Process for treating oil-containing sludge

A sludge treatment and sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problems of polluting the surrounding environment of the landfill, waste of petroleum resources, etc., achieving no secondary pollution, good treatment effect, energy low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

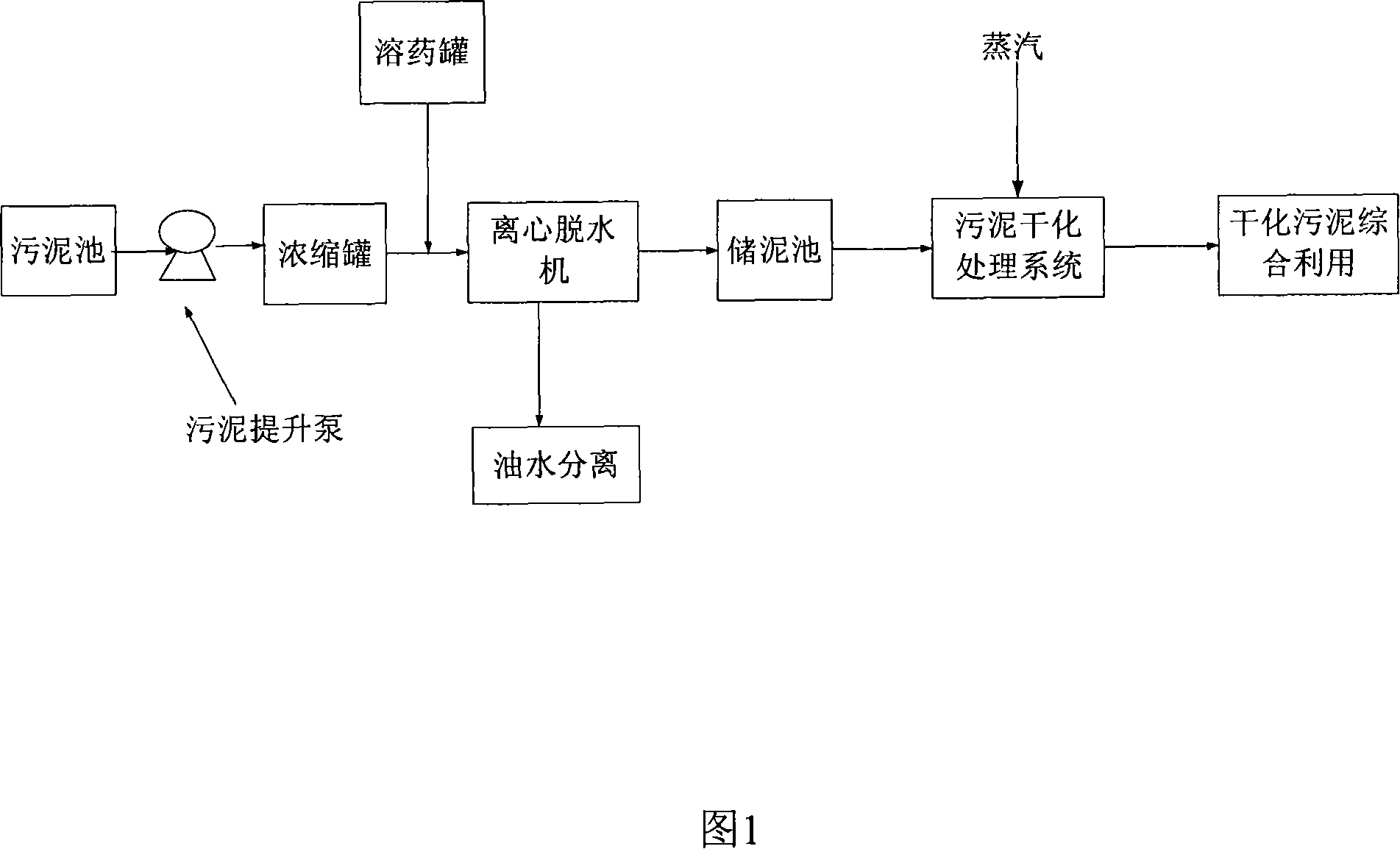

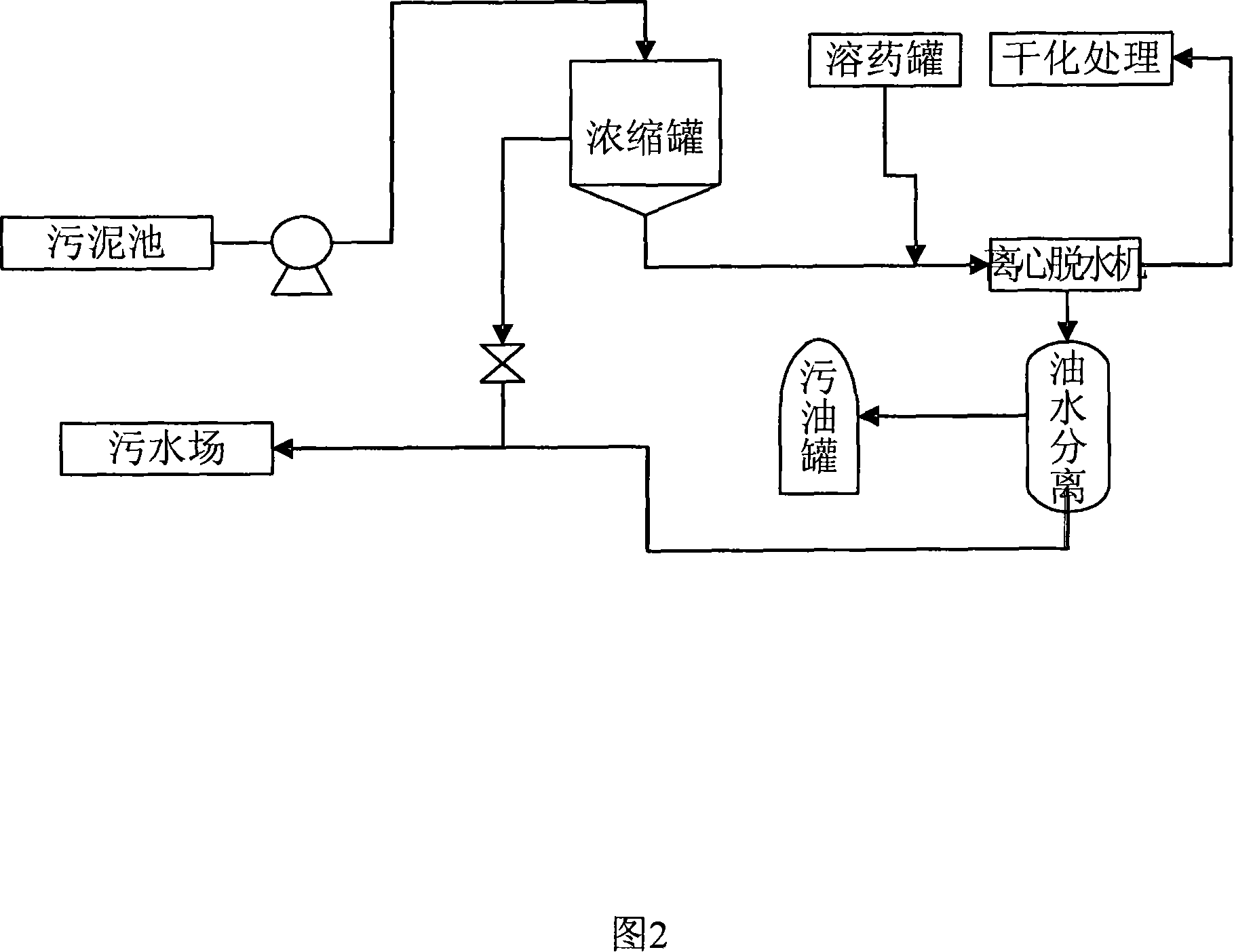

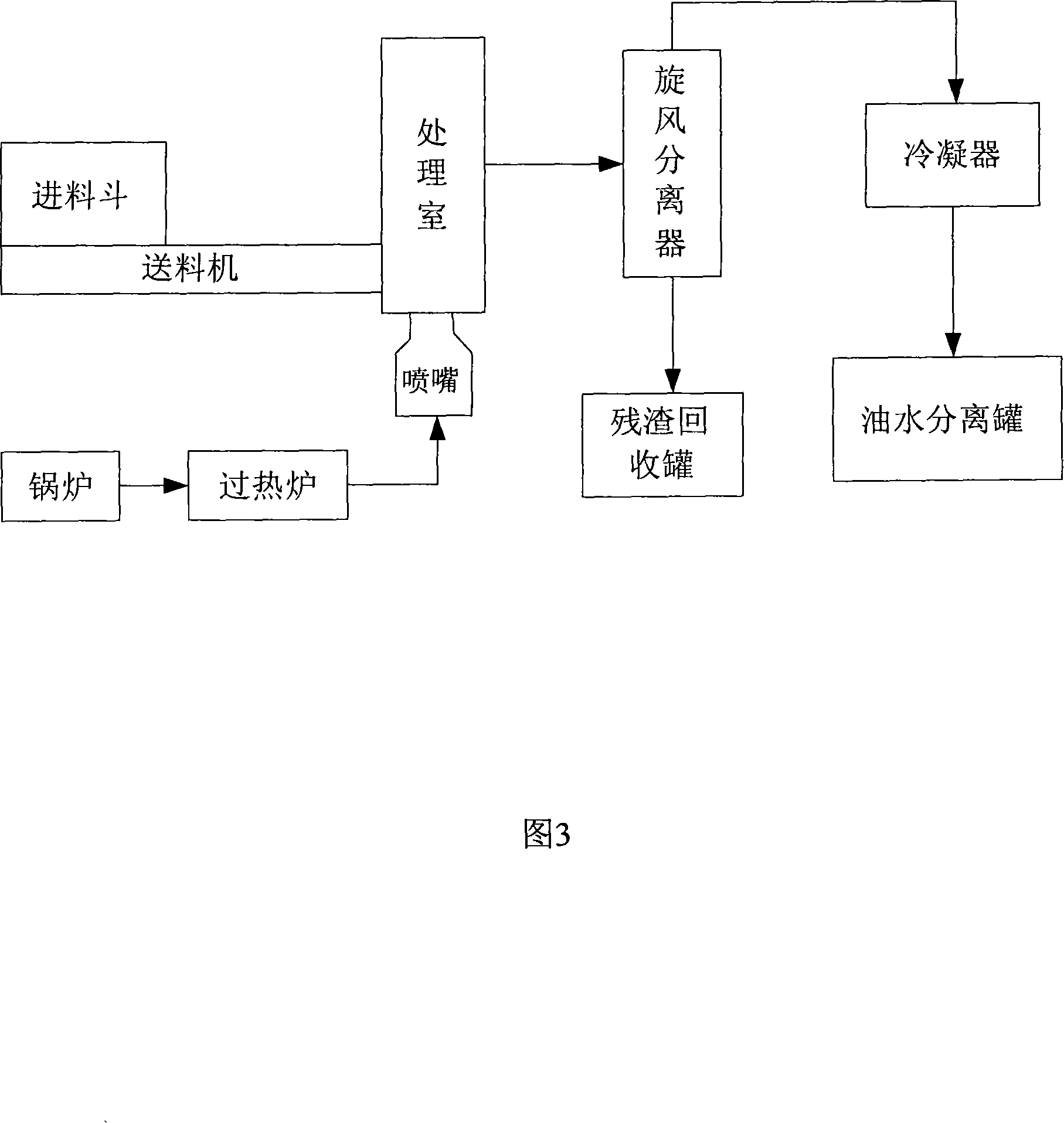

[0028] A method for treating oily sludge according to Embodiment 1 of the present invention includes a concentration treatment step, a flocculation-centrifugal dehydration step and a drying treatment step, wherein:

[0029] In the concentration treatment step, the oily sludge collected or collected in the sludge tank is lifted to the sludge concentration tank through the sludge pump, and the sludge in the concentration tank is mainly processed by gravity settlement to further remove part of the free water, and the reaction The time is 2 to 60 hours, and the concentrated sludge wastewater is discharged into the sewage field.

[0030] After concentration treatment, the moisture content of the sludge can be reduced from about 99% to about 97%-98%, and the volume is reduced by more than 50%.

[0031] The concentration treatment step of the oily sludge treatment method of this embodiment may further include a step of heating the sludge, and the sludge is heated to 20-60°C to ensure...

Embodiment 2

[0072] In this example, the oily sludge treatment method in Example 1 is further improved. In this example, the steps of fixing and removing sulfur-containing malodorous substances are added, and other aspects of the process flow are the same as those in Example 1.

[0073] The main odorous substances produced by oily sludge are hydrogen sulfide and mercaptans. The sulfide content in the "three sludges" produced by refining and chemical enterprises is generally very high, resulting in high hydrogen sulfide content in and around the three sludge treatment facilities and sites. In the traditional three sludge treatment process, the operators caused by hydrogen sulfide Poisoning and even death occurred frequently. The sulfides in the three sludges mainly come from two sources. One is that after the sulfur element in the processed crude oil is processed, part of it enters the sewage treatment plant in the form of sulfides, and finally enters the three sludges; the other part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com