Pulse combustion control system and control method

A technology of pulse combustion and pulse control, which is applied in the direction of controlling combustion, lighting and heating equipment, and can solve the problems of high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

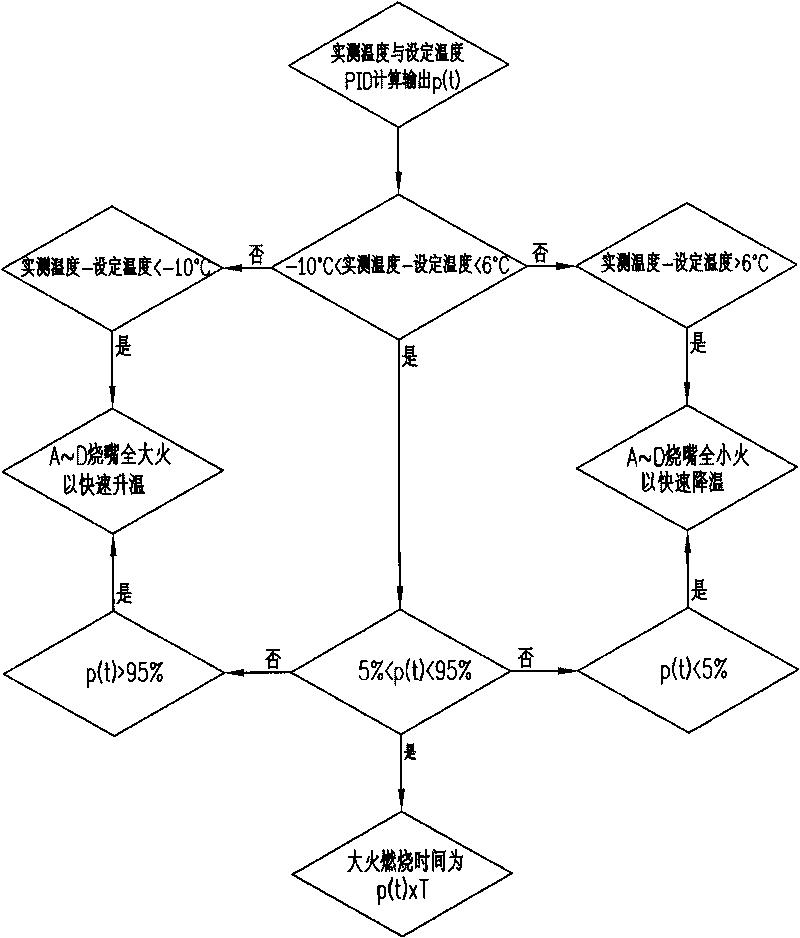

[0021] There are two forms of pulse combustion control, one is large and small fire pulses, and the other is open and close pulses. The procedures used in the two pulse forms are exactly the same. The applicable fuel for pulse control can be natural gas with high calorific value or clean coal gas. In the present invention, the control system adopts large and small fire pulse mode, and the fuel adopts natural gas as an example for illustration.

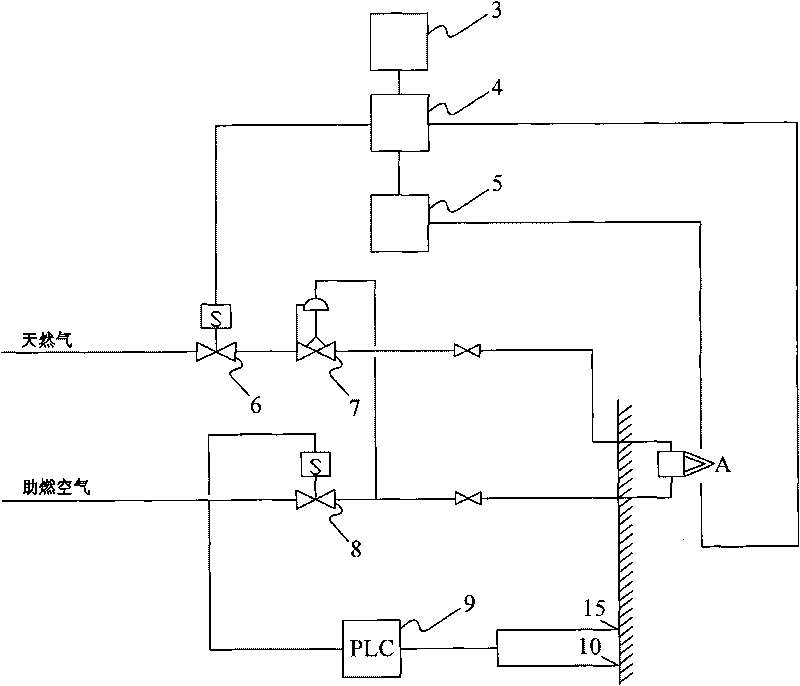

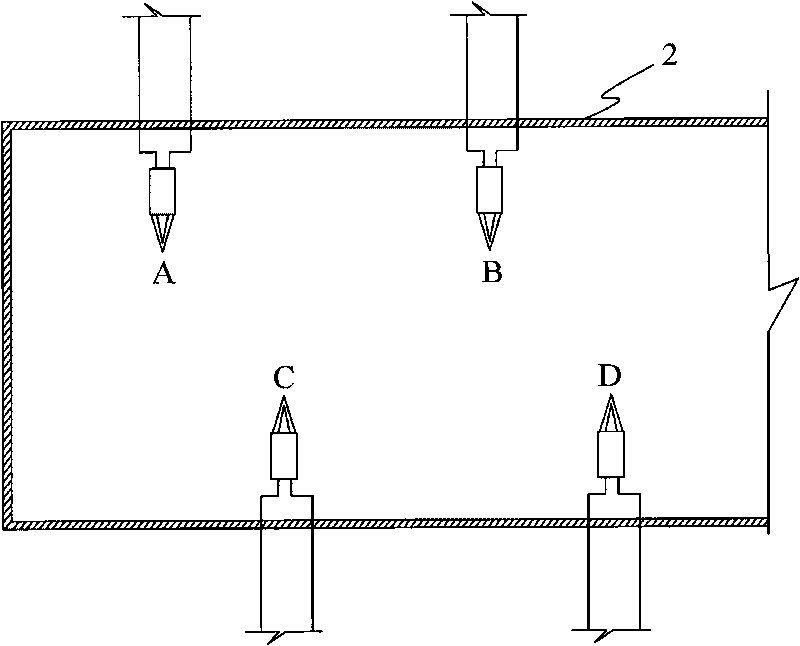

[0022] The pulse control system of the present invention is composed of three parts: ignition, flame monitoring and large and small fire pulse combustion control. The main structure of the system is as follows: figure 1 As shown, including: flame monitoring 3 (computer screen display), burner controller 4, ignition transformer 5, gas solenoid valve 6, air / gas proportional valve 7, air solenoid valve 8, PLC temperature control system 9, temperature detector 10. Temperature detector 15.

[0023] Each burner is equipped with a set of ig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com