Intelligent layout method used for rectangular part

A rectangular part and rectangle technology, applied in the field of intelligent layout of rectangular parts, can solve the problems of not considering the special process of rectangular parts, having fiber direction, low efficiency, large corners and remaining materials, etc., so as to improve the utilization rate of materials and shorten the Nesting time, the effect of meeting process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

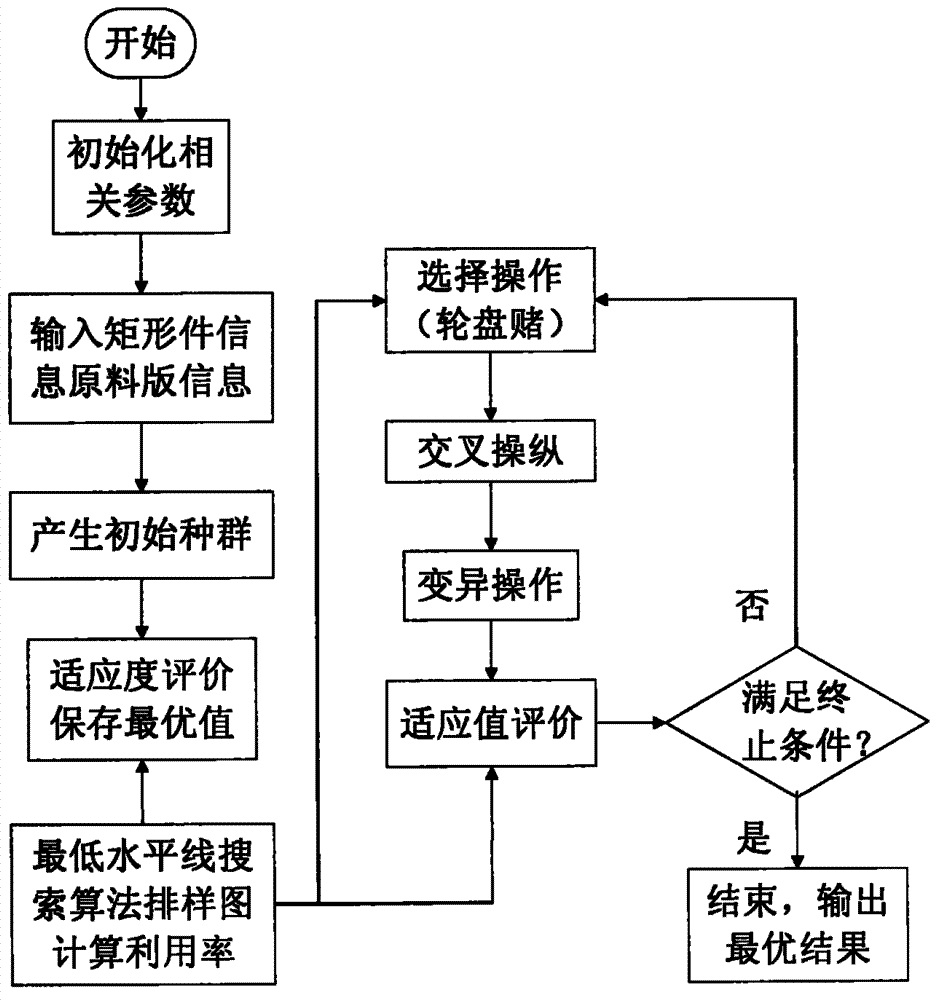

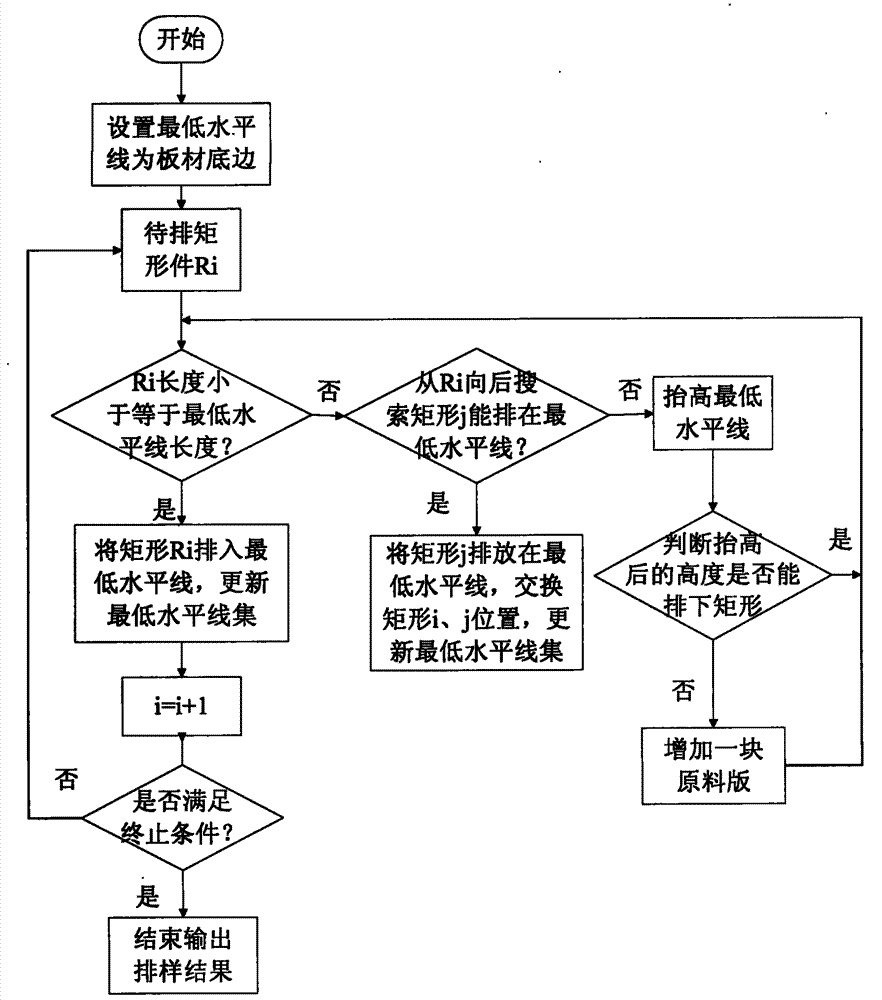

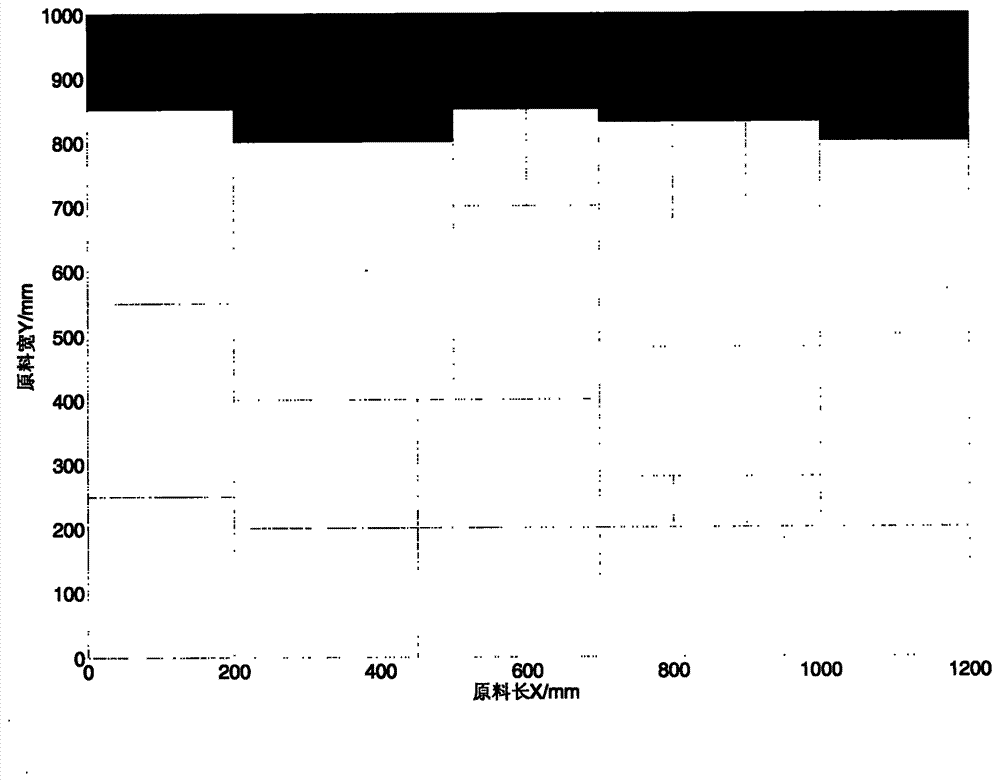

[0039] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the drawings and examples. It should be understood that the specific examples described here are only used to explain the present invention, but not to limit the present invention.

[0040] As understood by those skilled in the art, the layout method of rectangular parts has its own process requirements and constraints, specifically, for example:

[0041] (1) Any two rectangular pieces do not overlap and none of the rectangular pieces can exceed the boundary of the rectangular plate;

[0042] (2) The side of the discharged rectangular piece should be parallel to the side of the rectangular plate;

[0043] (3) The raw board itself has a fiber direction, and some rectangles in the rectangular pieces to be arranged have fiber direction requirements, and some rectangles do not have fiber directions. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com