Pressure plate automatic translation clamping machine

A technology of clamping machine and pressing plate, applied in clamping, workpiece clamping device, metal processing machinery parts, etc., to achieve the effect of stable performance, simple structure and satisfactory accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The details and working conditions of the specific device proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings.

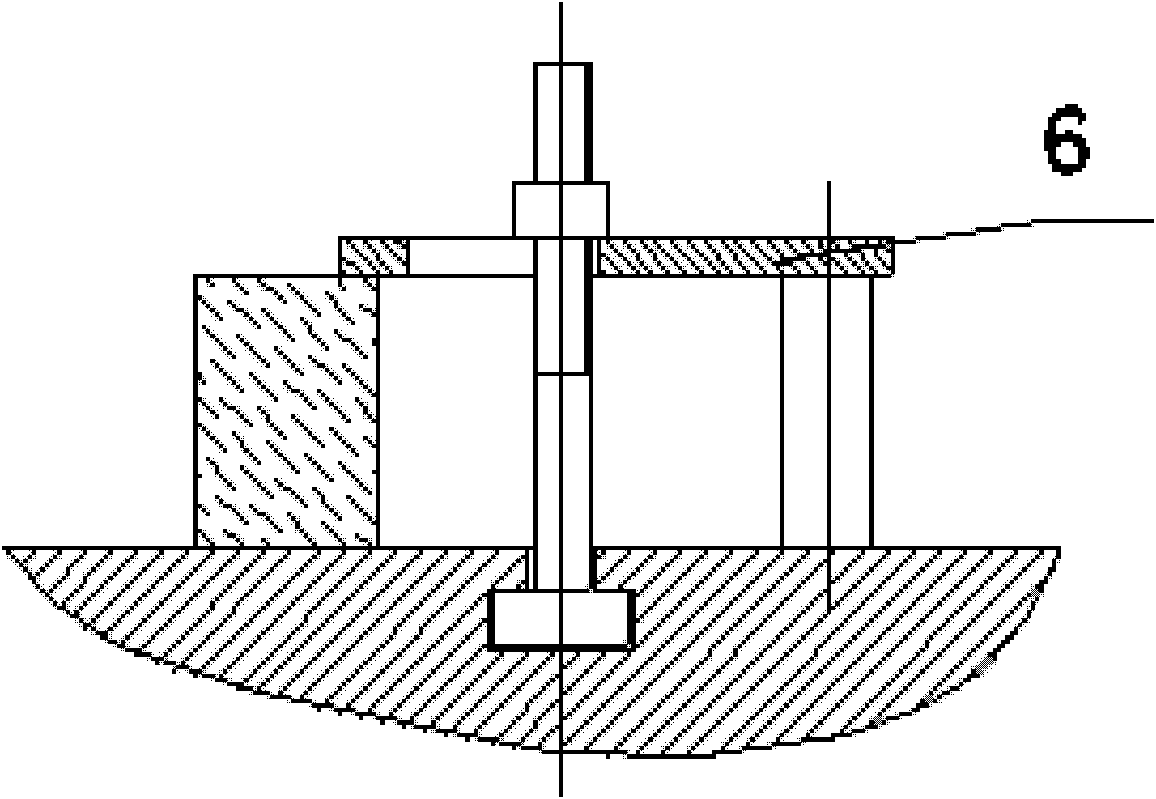

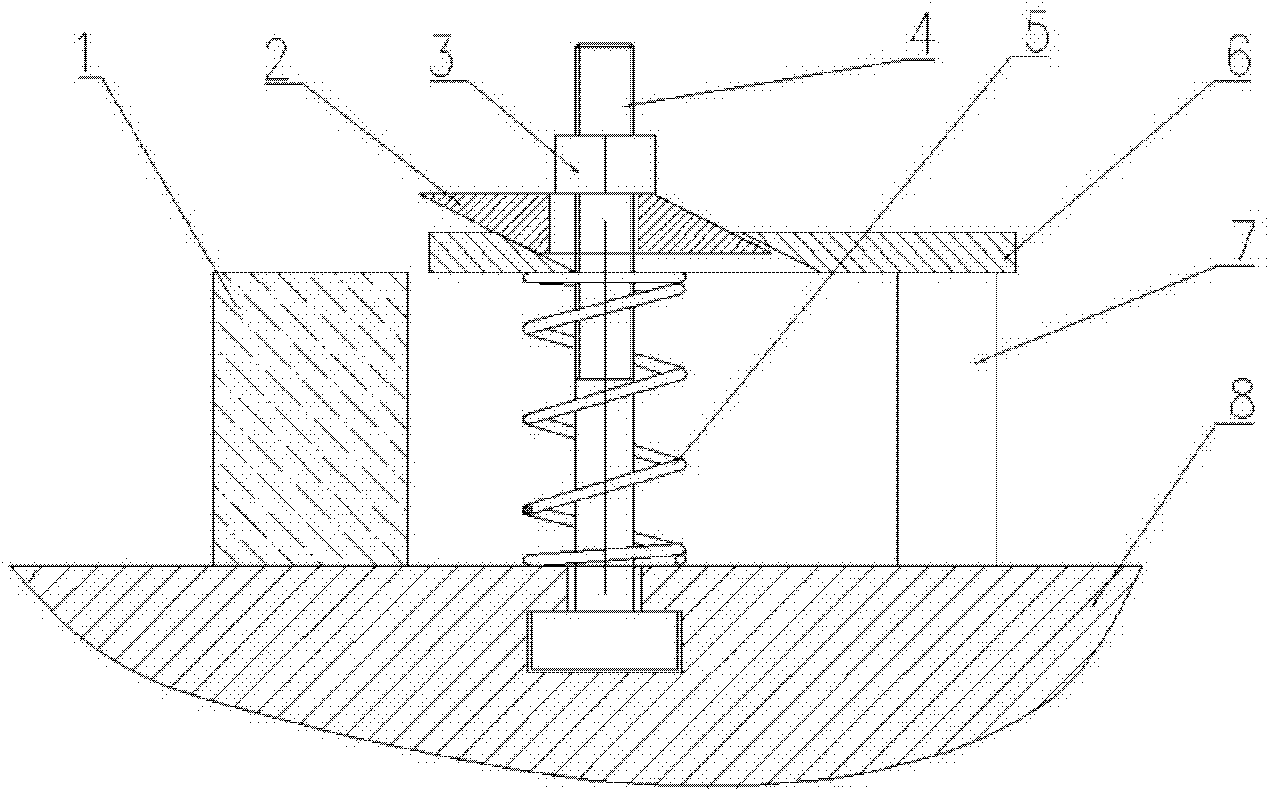

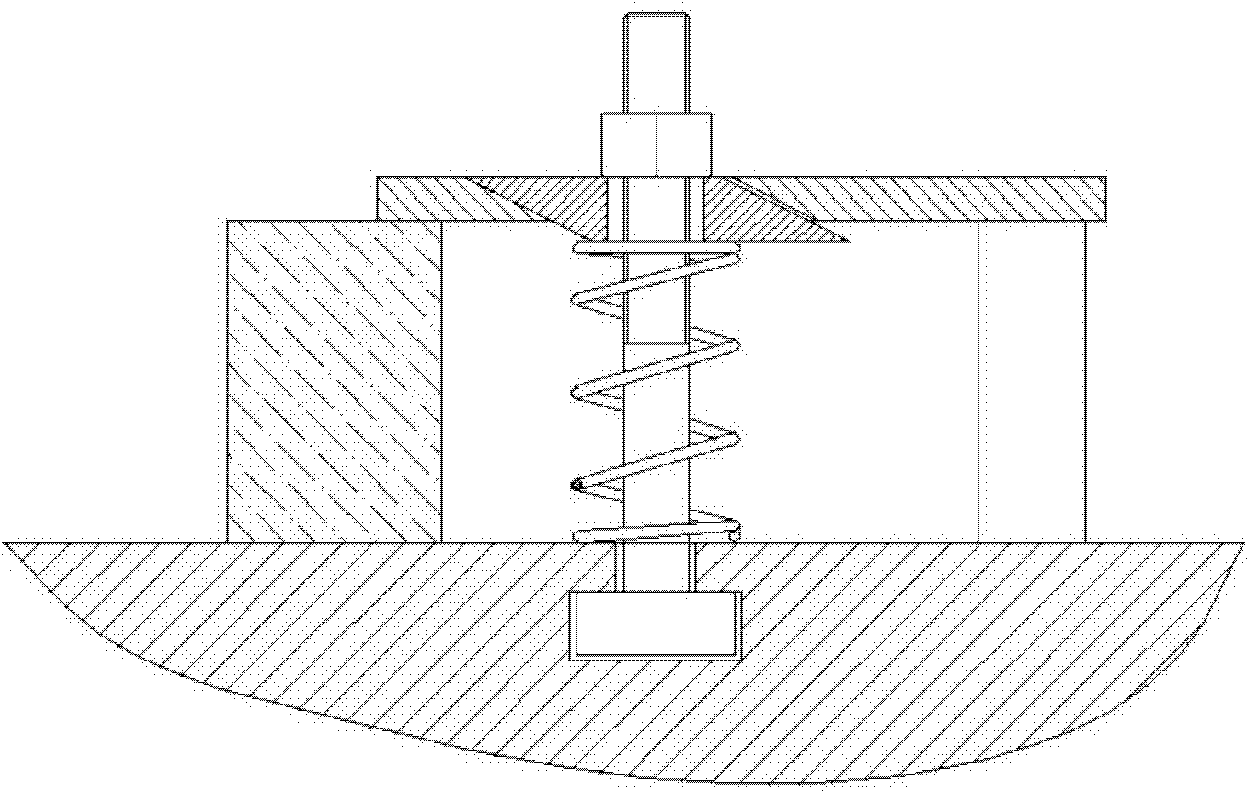

[0011] The pressing plate automatic translation clamping machine of the present invention includes inclined-plane pressing block 2, nut 3, T-shaped bolt 4, spring 5, pressing plate 6, spacer 7, workbench 8, and pressing plate 6 is kept horizontal under the elastic force of spring 5, and the inclined plane The pressing block 2 is in contact with the inclined plane on the left side of the pressing plate 6 under the action of the nut 3 . When the nut 3 is turned, the inclined-plane pressing block 2 moves down under the action of the nut 3, and pushes the pressure plate 6 to move left through the left inclined plane of the inclined-plane pressing block 2. At this time, due to the action of the spring 5, the pressing plate 6 remains horizontal. , until it moves above the workpiece, such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com