Reconstructable hybrid machine tool of mechanical system and fault tolerance correcting method

A technology of mechanical systems and machine tools, used in metal processing machinery parts, large fixed members, metal processing, etc., to solve problems such as quality accidents, quality or safety accidents, and major failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

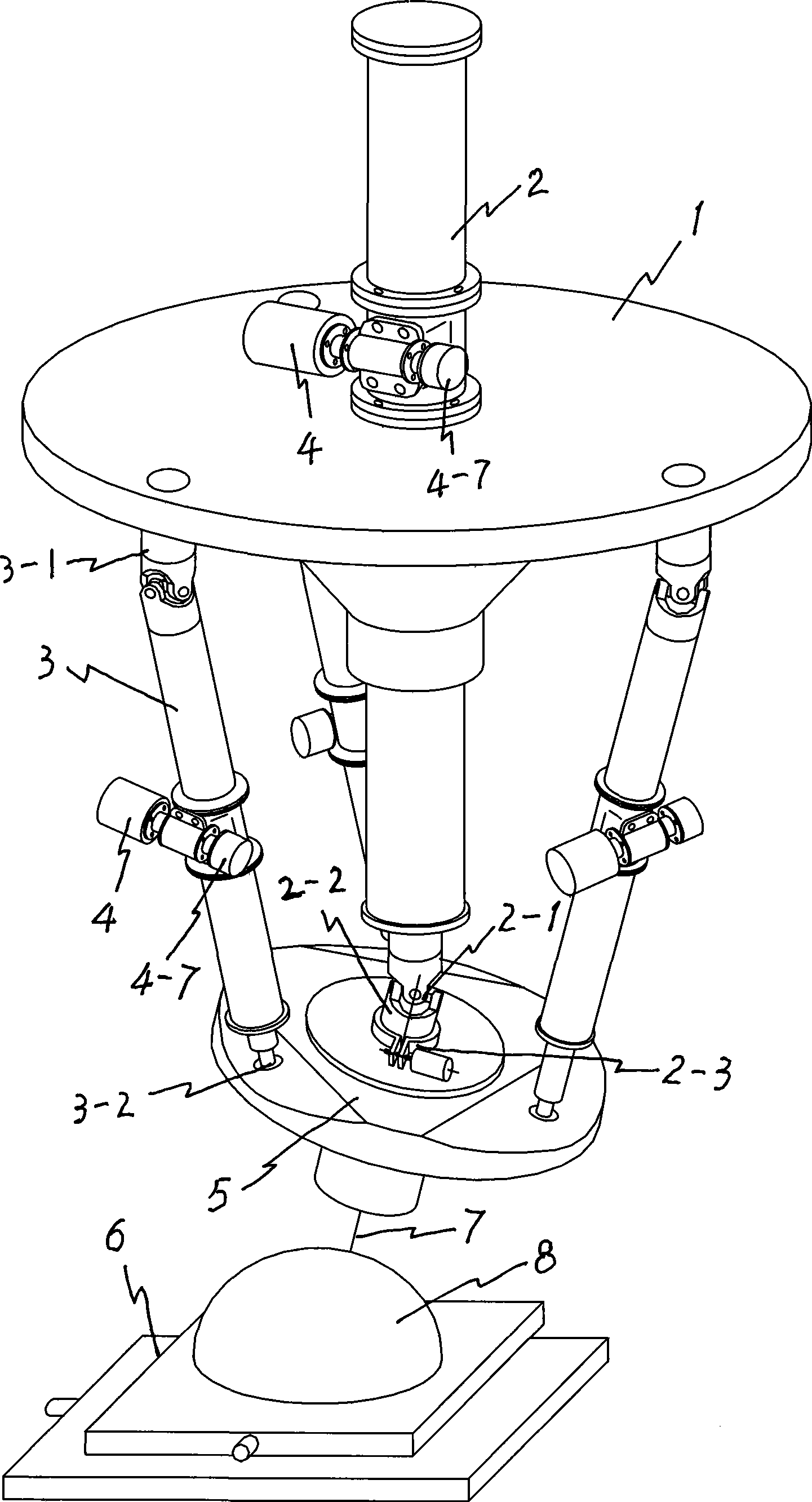

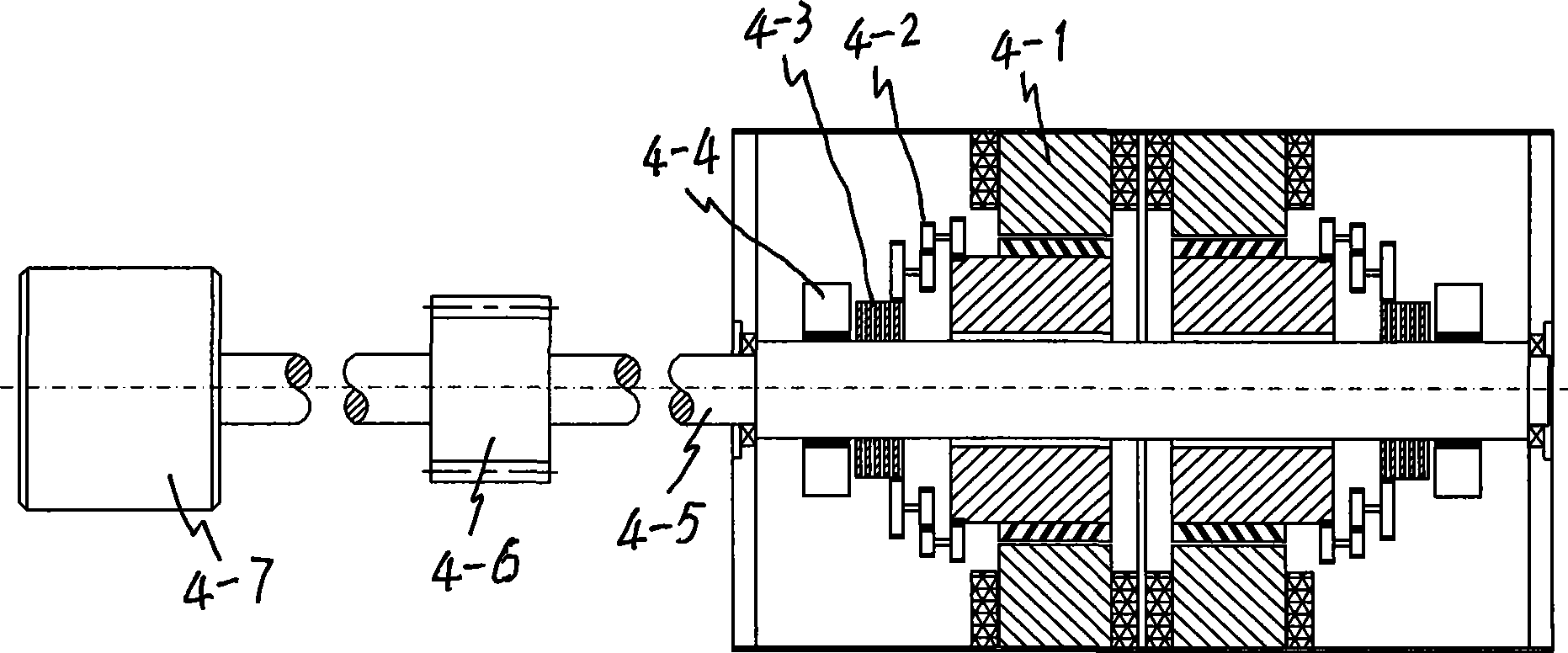

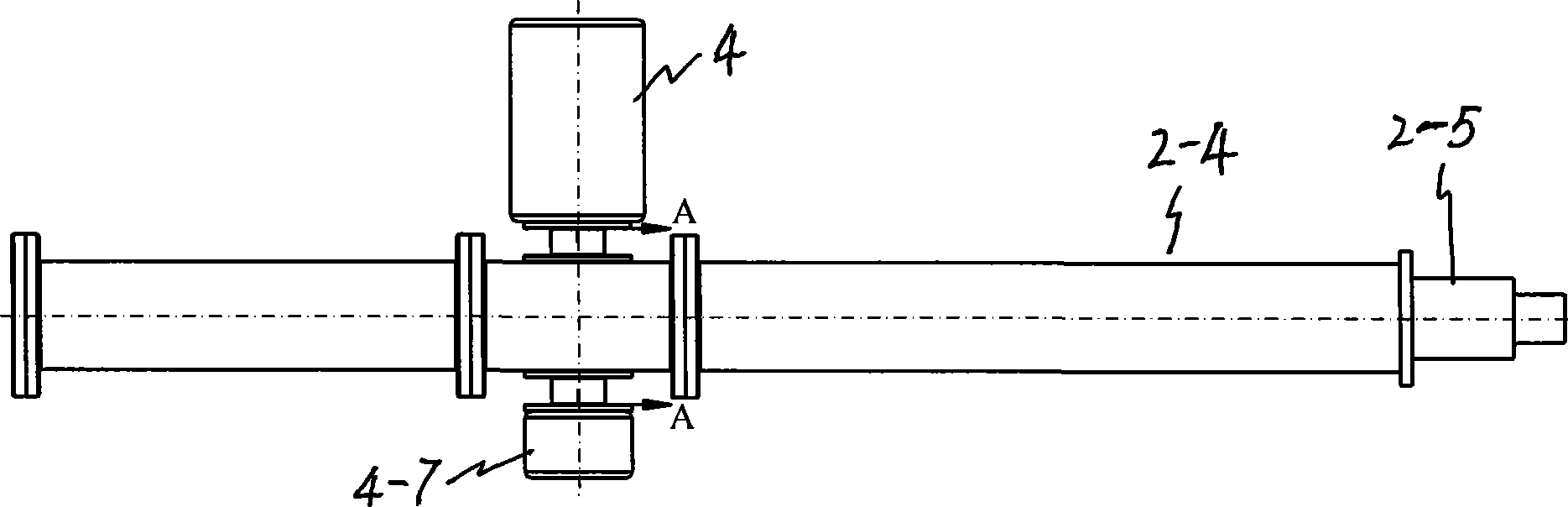

[0022] In this embodiment: there are four sets of redundant transmission devices 4, which are respectively fixed on the central leg 2 and three peripheral legs 3, and pass through the power output gear 4-6, the central leg mandrel 2-5 and the peripheral leg mandrel The gear rack 2-6 on the 3-4 meshes, the modulus (m) is 3, the number of teeth (z) of the gear 4-6 is 15; in the transmission system of the redundant transmission device 4, the power (P) of the servo motor 4-1 is 80W 1. The reduction ratio of the gear reduction mechanism 4-2 is 8, the clutch 4-3, and the brake 4-4 are all the same as the background technology. 5, and through the clutch 4-3 and the main shaft clutch connection, to transmit power, the model of the photoelectric encoder 4-7 is CN65M121759; the outer diameters of the center leg housing 2-4 and the mandrel 2-5 are respectively φ65mm, φ30mm, the outer diameters of the surrounding leg shells 3-3 and their mandrels 3-4 are φ45mm and φ20mm respectively; in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com