Waterproof air-permeable antibacterial anti-ultraviolet reinforced coating adhesive for textile and preparation method of waterproof air-permeable antibacterial anti-ultraviolet reinforced coating adhesive

An anti-ultraviolet and textile technology, used in textiles, papermaking, fiber processing, etc., can solve the problems of no antibacterial auxiliaries and reinforcing auxiliaries, weak antibacterial properties, no antibacterial properties, etc. Use simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

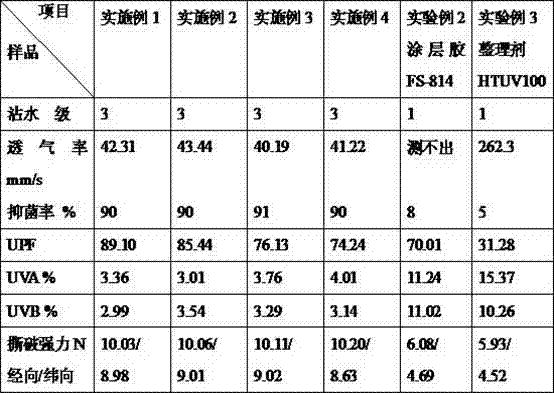

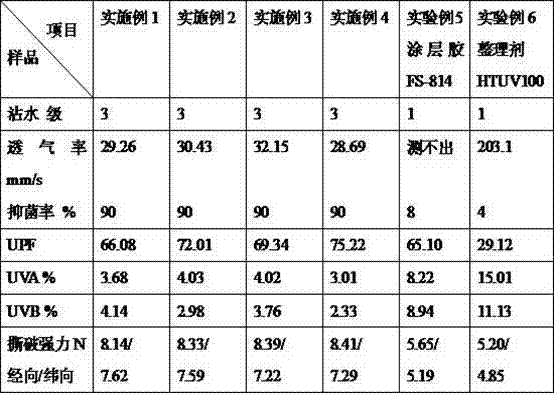

Embodiment 1

[0060] The weight ratio of each raw material: Add water-based polyurethane waterproof moisture-permeable adhesive 65, polyethylene glycol average number average molecular weight 600, TDI trimer curing agent 2.5 to the stainless steel reactor, stir for 25-30 minutes at room temperature; add anionic amino group Silicone oil emulsion 3.5, anionic or non-ionic fluorine waterproofing agent 5, phenylamide anionic antibacterial and deodorant finishing agent 5, stirring at room temperature for 20-25 minutes; adding nano zinc oxide powder 2.5, nano titanium dioxide powder 1.5, stirring at room temperature for 30-40 minutes, and filtering The product is discharged.

Embodiment 2

[0062] The weight ratio of each raw material: water-based polyurethane waterproof moisture-permeable adhesive 68, polyethylene glycol average number average molecular weight 600 12, TDI trimer curing agent 2, anionic amino silicone oil emulsion 3, anionic or non-ionic fluorine-based waterproofing agent 5.5 , Phenylamide anionic antibacterial and deodorant finishing agent 5.5, nano zinc oxide powder 2, nano titanium dioxide powder 2, the production process is as in Example 1.

Embodiment 3

[0064] The weight ratio of each raw material: water-based polyurethane waterproof and moisture-permeable adhesive 67, polyethylene glycol average number average molecular weight 600 10, TDI trimer curing agent 3.5, anionic amino silicone oil emulsion 4, anionic or non-ionic fluorine-based waterproofing agent 6 , Phenylamide anionic antibacterial and deodorant finishing agent 7, nano zinc oxide powder 1.5, nano titanium dioxide powder 1.0, the production process is as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com