Preparation method of superhydrophobic woven fabric for oil-water separation

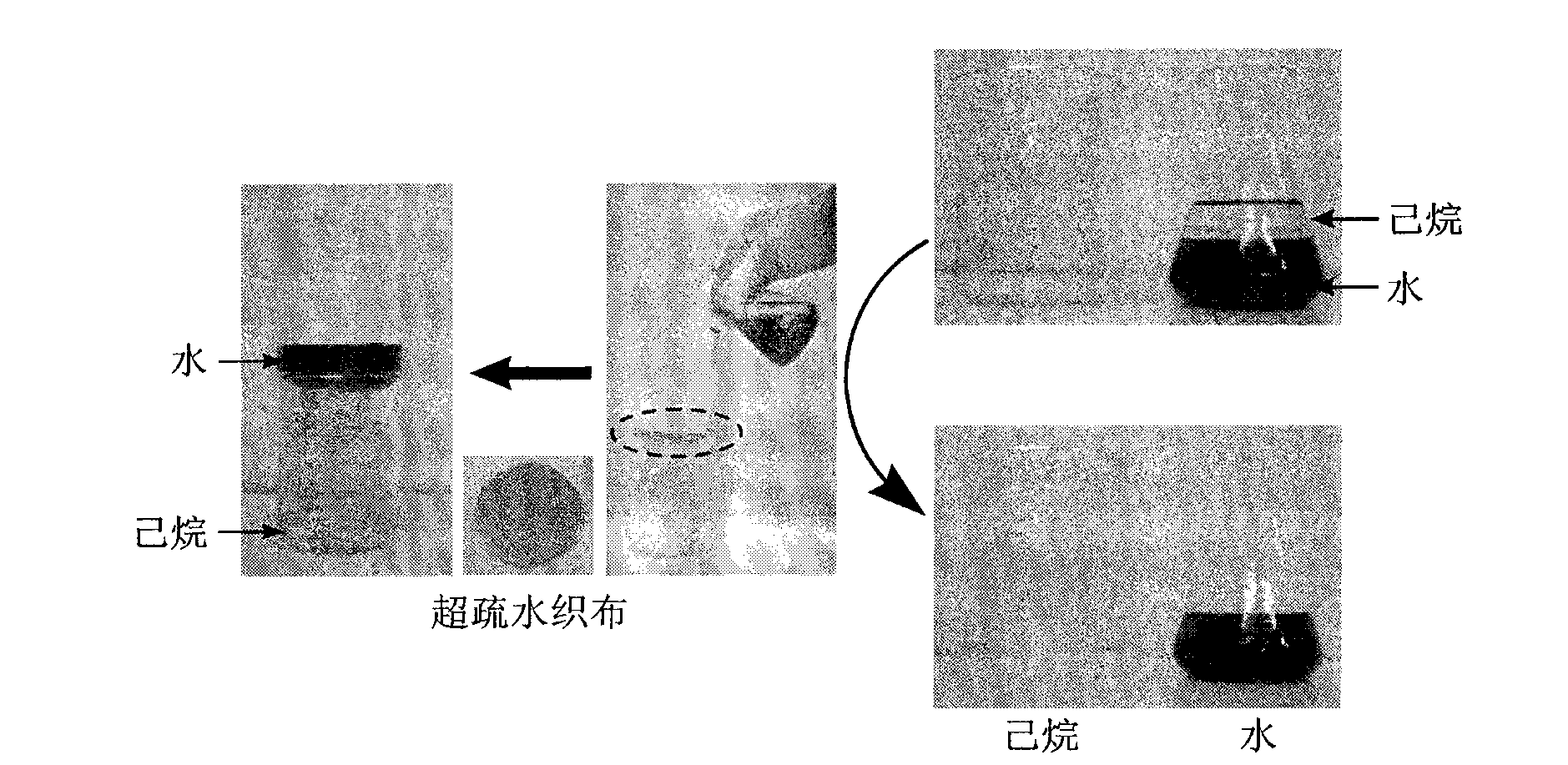

An oil-water separation and super-hydrophobic technology, which is applied in the direction of separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of poor stability of super-hydrophobic substrates, cannot be used repeatedly, and does not have universal applicability, so as to increase roughness , easy to operate, realize the effect of oil-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] At room temperature, a commercially available woven cloth of 5 cm × 5 cm was immersed in Fe with an average particle size of 40 nm. 3 o 4 After 5 minutes in the nanoparticle aqueous solution, the cloth was taken out, washed with water, and dried at 80° C. for several minutes. The dried modified Fe 3 o 4 The woven fabric of nanoparticles was immersed in 5mmol / L octadecyl mercaptan, and reacted at room temperature for 24h. After the reaction, the woven fabric is taken out, washed with absolute ethanol to remove unloaded stearyl mercaptan, and finally the woven fabric is dried to obtain the superhydrophobic woven fabric of the present invention.

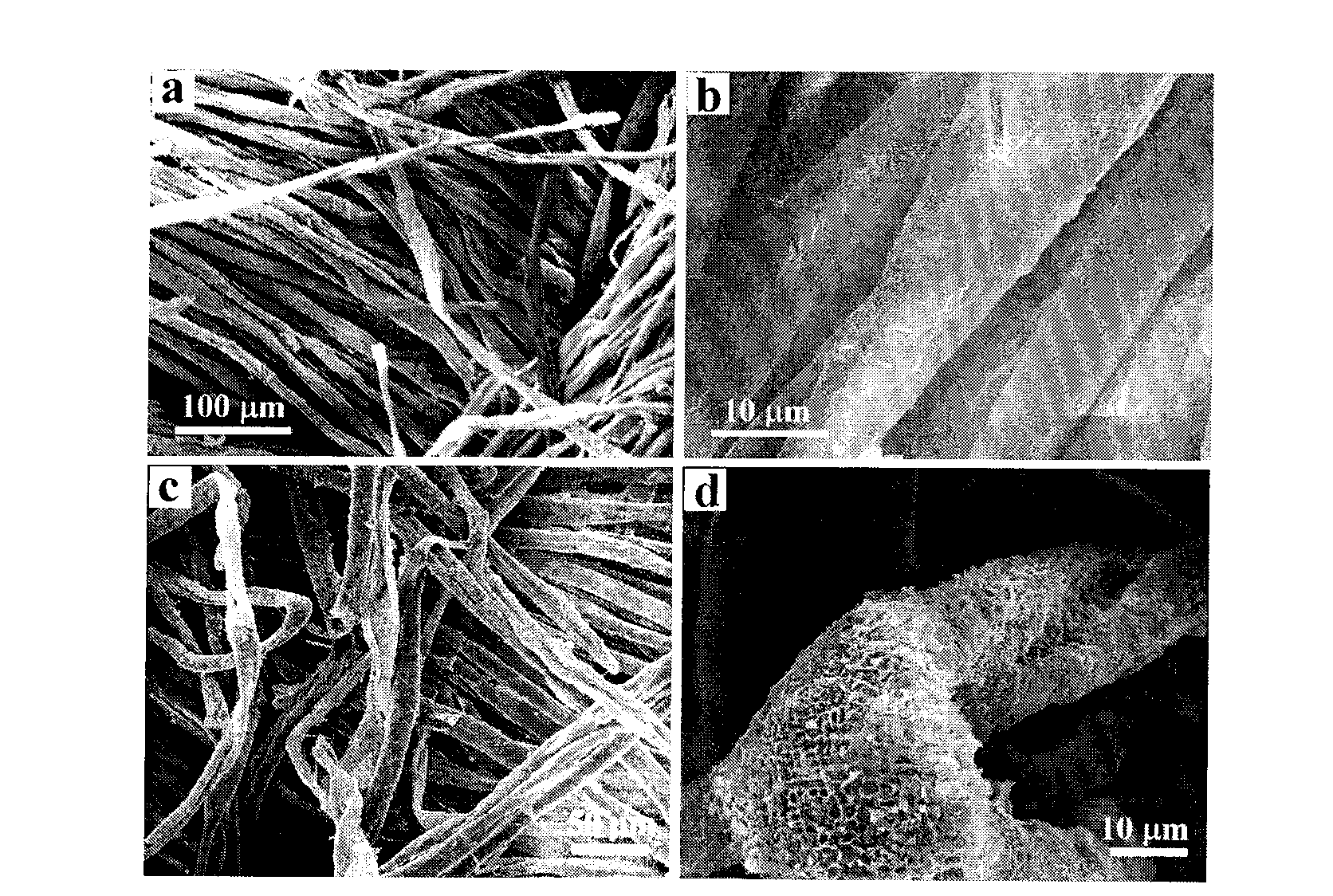

[0031] The scanning electron micrographs of the superhydrophobic woven fabric before surface modification (a, b) and after surface modification (c, d) are as follows figure 1 As shown, the surface of the woven fabric changed from smooth before modification to rough after modification.

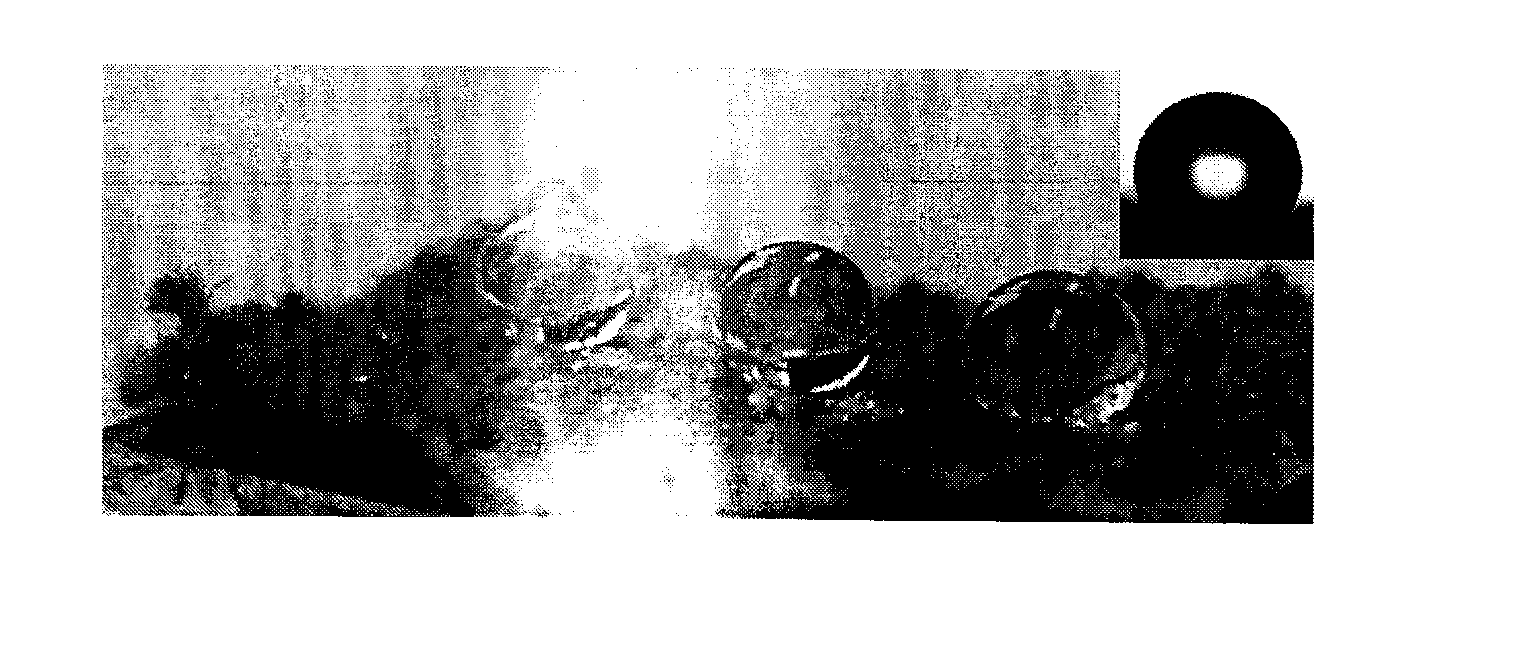

[0032] The static contact angle photos...

Embodiment 2

[0037] At room temperature, immerse a commercially available fabric of 5 cm x 5 cm in an aqueous solution containing FeO nanoparticles with an average particle size of 30 nm, take out the fabric after 10 minutes, wash it with water, and dry the fabric at 70 °C a few minutes. Then the dried woven fabric modified with FeO nanoparticles was immersed in 10 mmol / L octadecyl mercaptan, and reacted at room temperature for 24 h. After the reaction, the fabric was taken out, washed with ethanol to remove the unloaded stearyl mercaptan, and finally the fabric was dried to obtain a superhydrophobic fabric.

[0038] The contact angle between the superhydrophobic woven fabric and water is 158.2°, showing good superhydrophobic properties. The superhydrophobic woven fabric is used in the filter layer, which can realize rapid and efficient separation of oil-water mixture, and is resistant to high temperature and washing.

Embodiment 3

[0040]At room temperature, a commercially available fabric of 5 cm × 5 cm was immersed in an aqueous solution containing CoO nanoparticles with an average particle size of 50 nm, and the fabric was taken out for 15 minutes, washed with water, and then dried at 60 °C for several days. minute. Then the dried woven fabric modified with CoO nanoparticles was immersed in 20 mmol / L cetyl mercaptan, and reacted at room temperature for 12 h. After the reaction, the woven fabric was taken out, washed with ethanol to remove cetyl mercaptan that could not be loaded, and finally the woven fabric was put into an oven to dry to obtain a superhydrophobic woven fabric.

[0041] The superhydrophobic woven fabric has a contact angle of 156.1° with water, exhibits good superhydrophobic properties, can realize rapid and efficient separation of oil-water mixtures, and is resistant to high temperature and washing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com