Electret film, preparation method, application, and air purification device

An electret and thin film technology, applied in the field of electret materials and preparation, can solve the problems of low charge density and storage stability, charge failure, etc., achieve high charge density and electrostatic voltage, not easy to decay, and improve performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

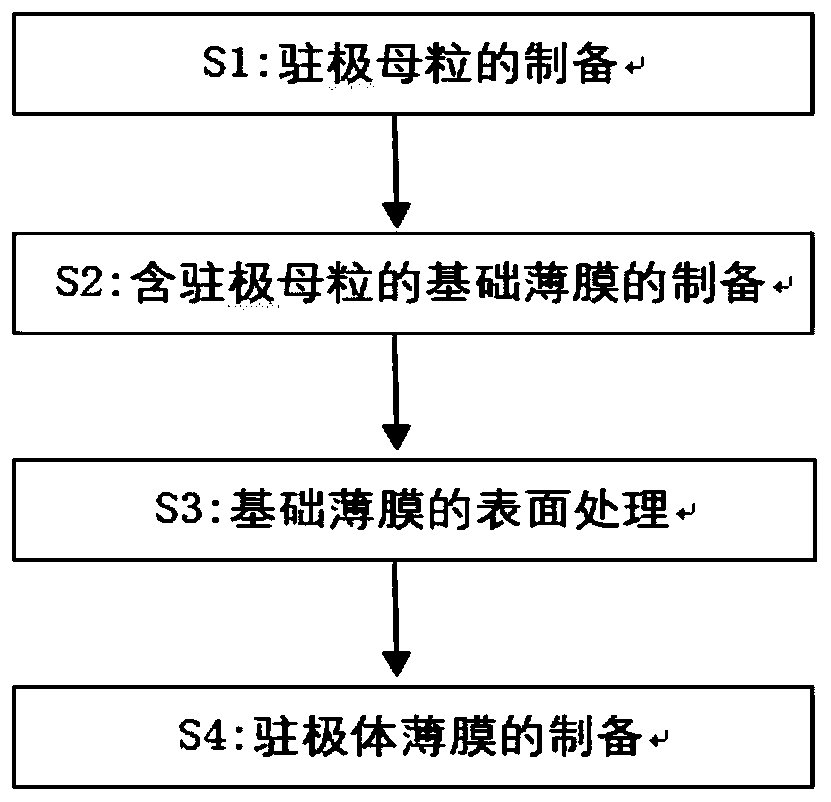

[0116] In a second aspect, in some embodiments, a method for preparing an electret film is provided, comprising the following steps:

[0117] making a base film from a mixture comprising a first polymer and an electret masterbatch;

[0118] The base film is subjected to electret treatment to obtain an electret film.

[0119] The preparation method of the film material has the characteristics of simple process operation, convenient manipulation, low cost, suitable for mass production and the like.

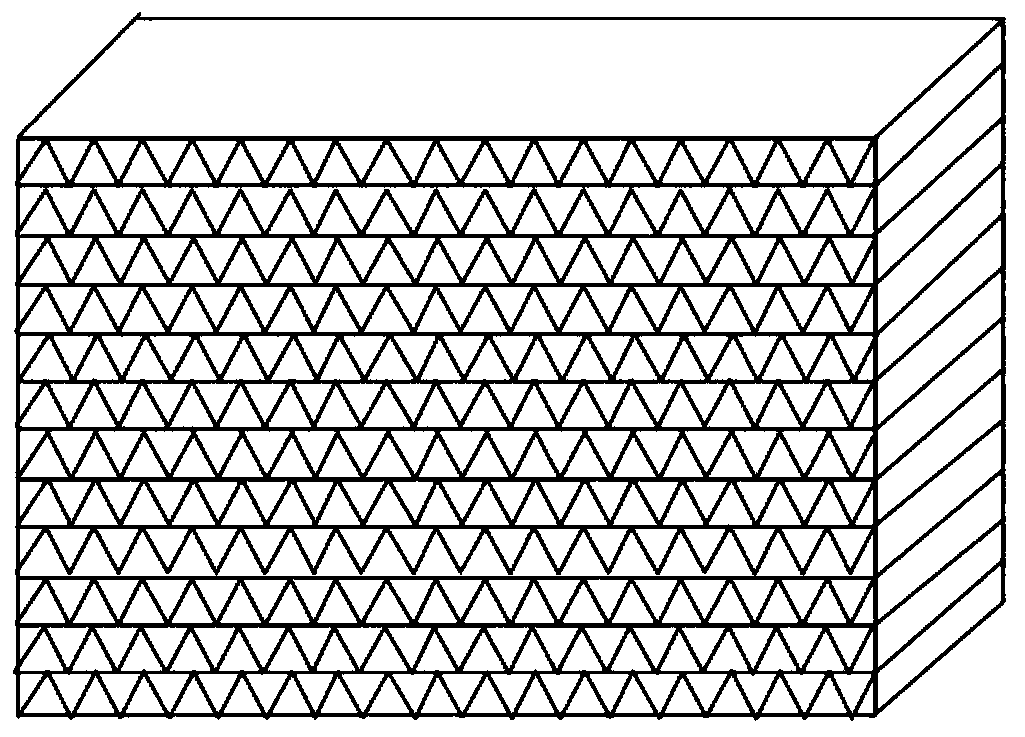

[0120] Specifically, after mixing the electret masterbatch and the polymer material according to a certain ratio, the base film is obtained by melt extrusion, and then the base film is subjected to surface treatment and corona electret to obtain a high-performance electret Membrane air filter material. The electret film air filter material produced by the invention has high charge density and static voltage, can generate a durable and stable electrostatic field and is not easy to ...

Embodiment 1

[0147] 1. An electret film, mainly prepared from the following raw materials:

[0148] Polypropylene and electret masterbatch, wherein, the weight content of electret masterbatch is 5%;

[0149] The electret masterbatch includes the following components by weight: 2.5% nano active titanium dioxide, 2.5% nano active calcium carbonate, 5% nano tourmaline, 2.5% substituted aryl carboxylate aluminum salt, 5% hindered amine, 5% phosphite , 5% pentaerythritol ester and 72.5% polypropylene.

[0150] 2, the preparation method of electret thin film, comprises the following steps:

[0151] 2.5% nano active titanium dioxide, 2.5% nano active calcium carbonate, 5% nano tourmaline, 2.5% substituted aryl carboxylate aluminum salt, 5% hindered amine, 5% phosphite, 5% pentaerythritol ester and 72.5% polypropylene Add it to a high-speed mixing mixer and mix and disperse for 20-30 minutes, extrude and granulate with a twin-screw extruder at an extrusion temperature of 180-240°C; then dry the ...

Embodiment 2

[0158] The difference between this embodiment and embodiment 1 is that the weight content of electret masterbatch is 2%; the rest are the same as embodiment 1.

[0159] In this embodiment, the test results show that the resistance is 0.1 Pa and the filtration efficiency is 32.962%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com