Finishing method of dry-touch and cool knitted underwear or fabric

A technology for underwear and fabrics, applied in fiber processing, textiles and papermaking, natural fibers, etc., can solve the problems of wet and cold, poor moisture removal performance, etc., and achieve the effect of strong wicking effect and strong moisture absorption and perspiration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Cotton underwear or fabric

[0020] Hydrophobic core material temperature-sensitive microcapsule finishing: underwear or fabrics are put into a solution with a bath ratio of 1:8, temperature-sensitive microcapsules cwjn-110% (weight to fabric), penetrant JFC 0.5% (weight to fabric), Helizarin binder FWT 6% (to fabric weight), soaked at room temperature, dehydrated, dried (100°C×3min), baked (150°C×40s)

[0021] Post-treatment: add hydrophilic soft oil 30985% (weight to fabric), penetrant JFC 3% (weight to fabric), adjust pH to 5.5 with HAC, bath ratio 1:8, immerse at 60°C for 30 minutes, and then dehydrate directly ,drying.

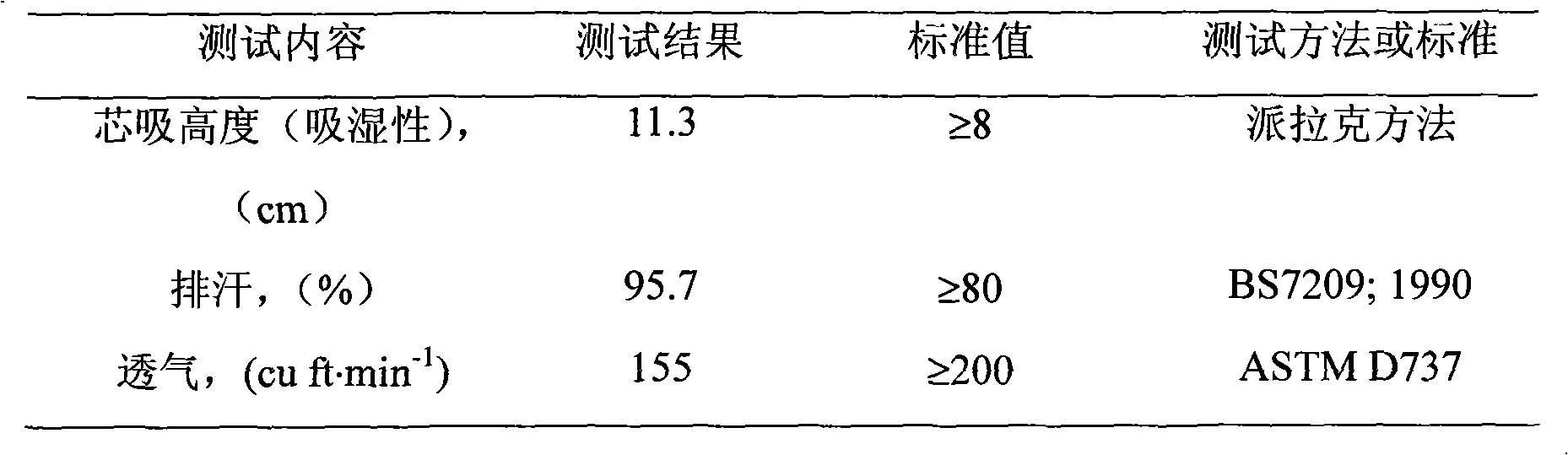

[0022] The moisture absorption, perspiration, and air permeability tests were carried out on the above-mentioned finished samples, and the results are shown in Table 1.

[0023] Table 1

[0024]

Embodiment 2

[0025] Example 2: Cotton / wool blend underwear or fabric

[0026] Hydrophobic core material temperature-sensitive microcapsule finishing: underwear or fabrics are put into a solution with a bath ratio of 1:8, temperature-sensitive microcapsules cwjn-112% (weight to fabric), penetrant JFC 1.5% (weight to fabric), Evo Protect FXM 8% (to fabric weight), soak at room temperature, dehydrate, dry (100°C×3min), bake (150°C×60s)

[0027] Post-treatment: add 8% hydrophilic agent Lurotex, 0.5% penetrant JFC, adjust pH to 5.5 with HAC, bath ratio 1:10, immerse at 60°C for 40min, dehydrate directly, and dry.

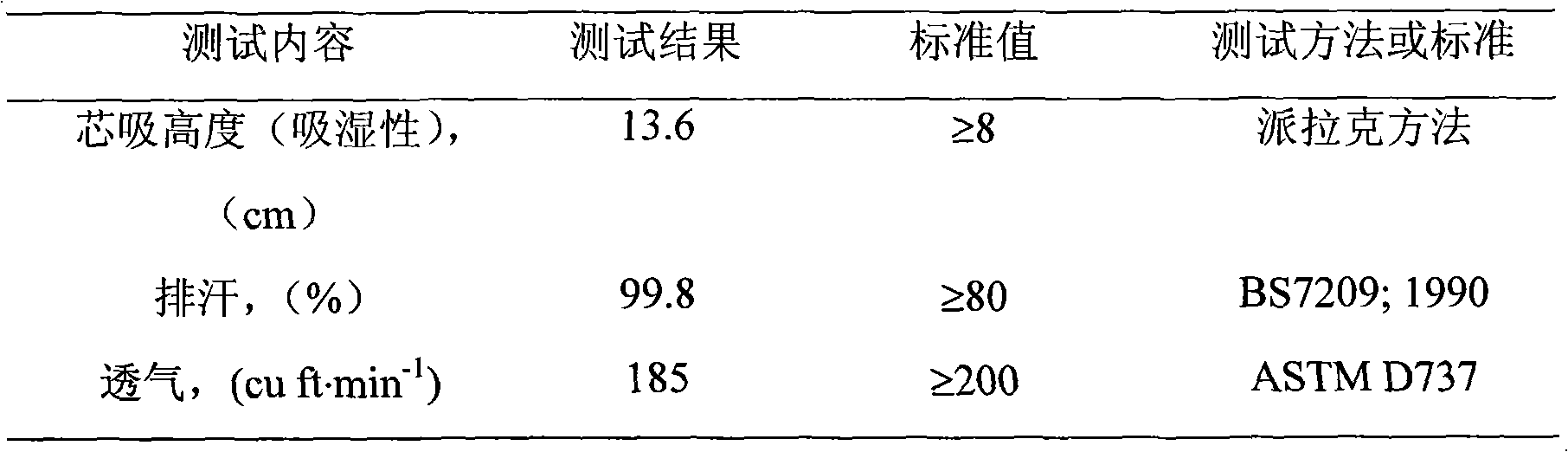

[0028] The moisture absorption, perspiration, and air permeability tests were carried out on the above-mentioned finished samples, and the results are shown in Table 2.

[0029] Table 2

[0030]

Embodiment 3

[0031] Embodiment 3: silk / cashmere blended underwear or fabric

[0032] Hydrophobic core material temperature-sensitive microcapsule finishing: underwear or fabrics are put into a solution with a bath ratio of 1:8, temperature-sensitive microcapsules cwjn-18% (weight to fabric), penetrant JFC 0.5% (weight to fabric), Helizarin binder 44386% (to fabric weight), soaked at room temperature, dehydrated, dried (80°C×3min), and then baked (120°C×90s)

[0033] Post-treatment: add hydrophilic agent Sliligen SIH Nano 8% (weight to fabric), penetrant JFC 1% (weight to fabric), adjust pH to 6 with HAC, bath ratio 1:10, after immersion at 60°C for 30min, Direct dehydration, drying.

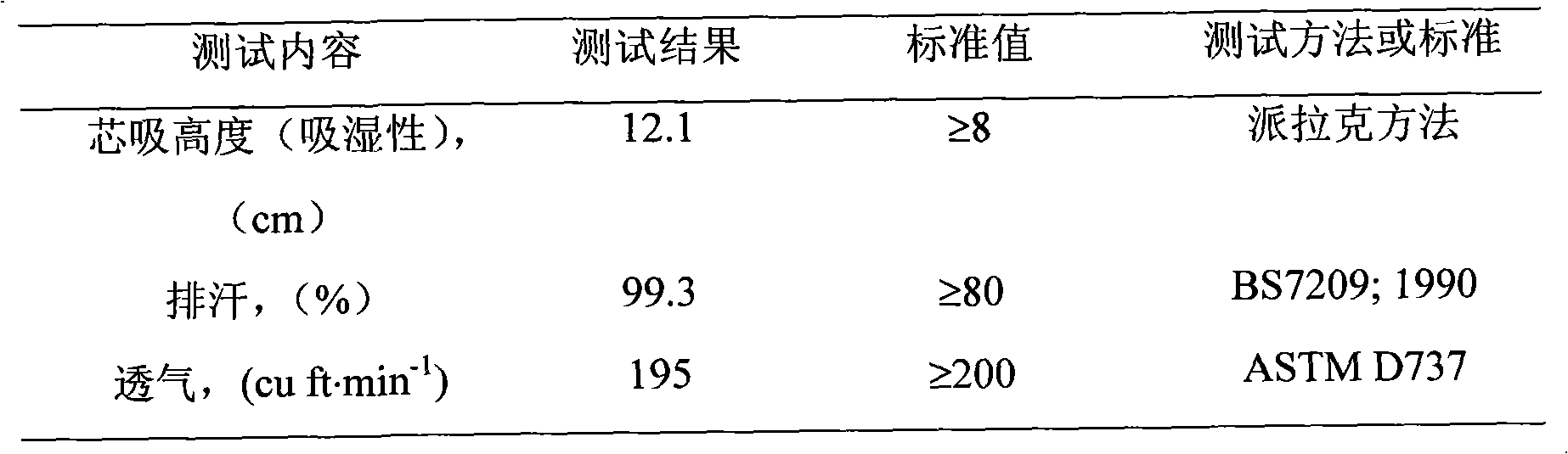

[0034] The moisture absorption, perspiration, and air permeability tests were carried out on the above-mentioned finished samples, and the results are shown in Table 3.

[0035] table 3

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com