Flame-proof treatment method for light and thin natural fiber material

A technology of natural fiber, flame retardant treatment, applied in the direction of fiber treatment, natural fiber, flame retardant fiber, etc., can solve the problem of unsatisfactory effect, ultra-thin, ultra-light, ultra-fine and ultra-flexible fiber materials can not obtain good results, etc. , to achieve the effect of safe and reliable ecological indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

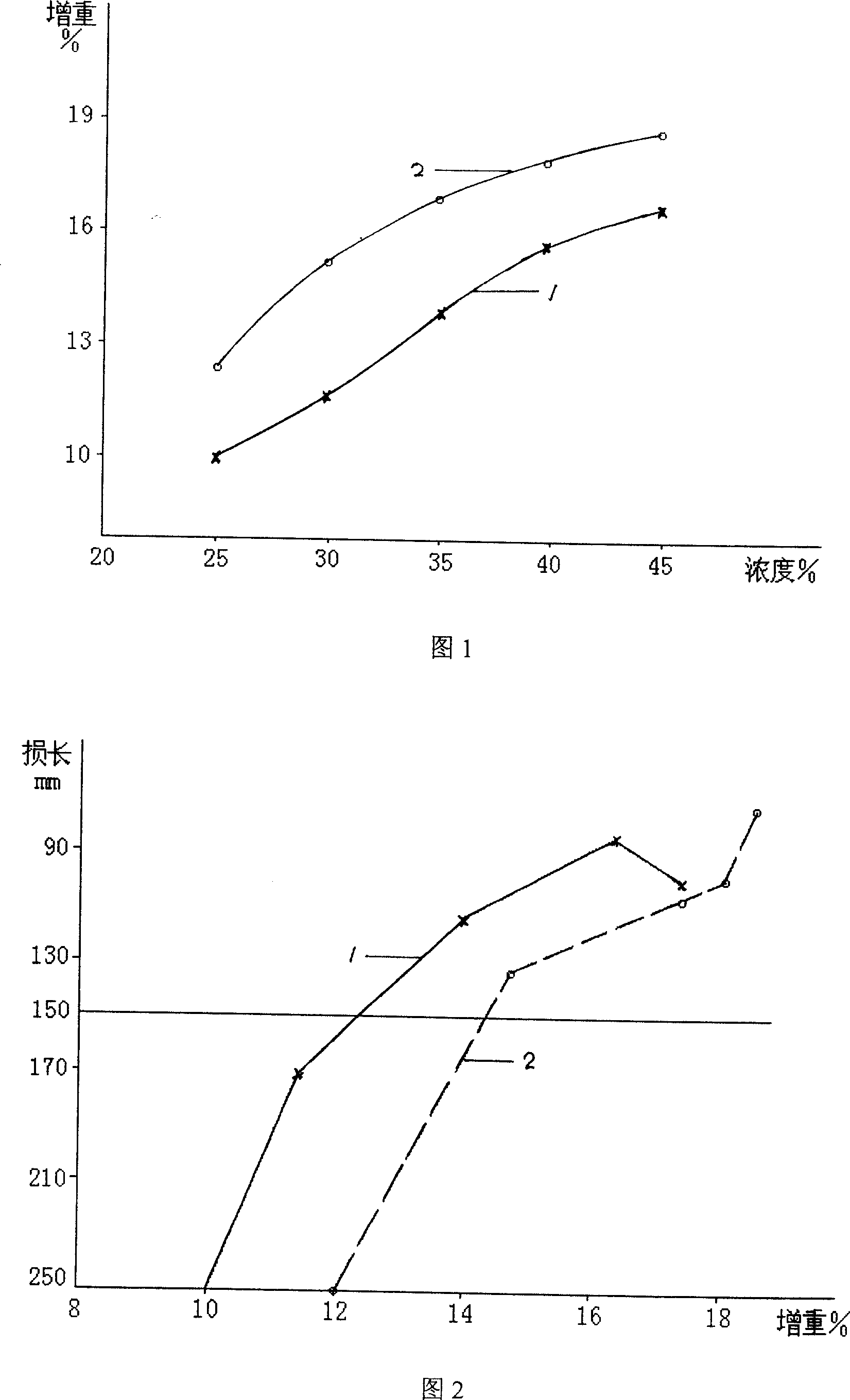

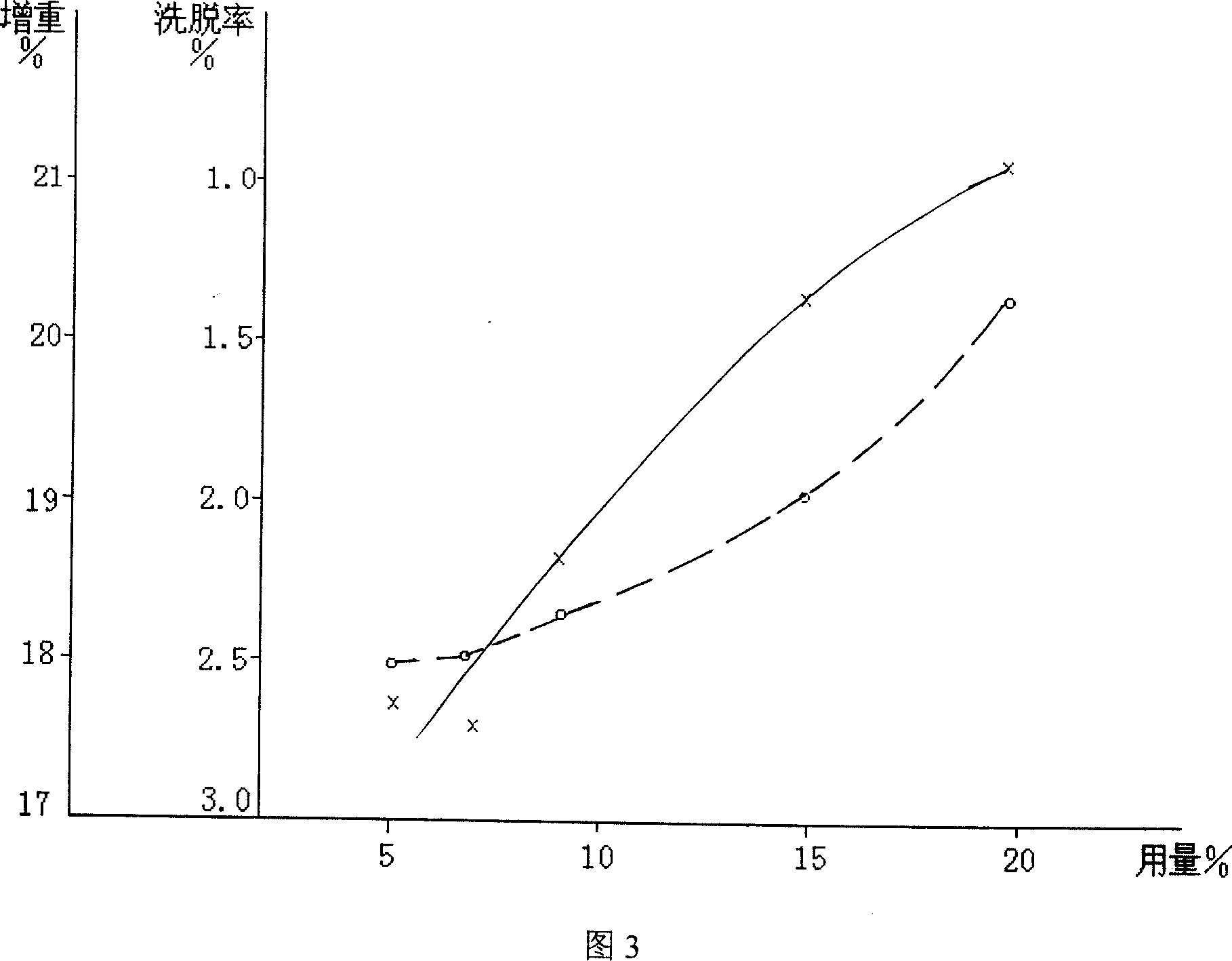

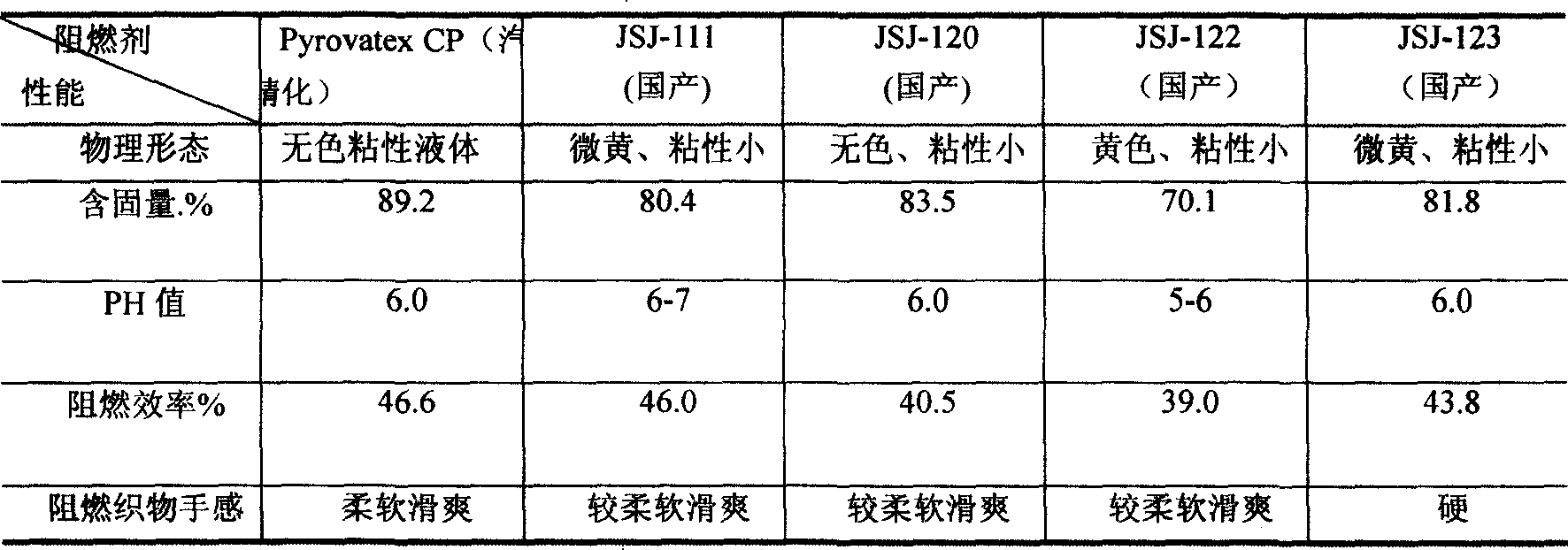

[0027] 1. The effect of the amount of flame retardant on the flame retardancy and softness of fiber materials

[0028] Due to the characteristics of lightness, bulkiness, softness and large specific surface area of ultra-microfiber materials, the amount of air contained in unit mass of fiber materials is relatively large, and the oxygen supply is sufficient during combustion, so ultra-microfiber materials are easier to ignite and burn. Ecologically efficient flame retardants are selected during flame retardant processing and the amount of flame retardants is appropriately increased.

[0029] At present, the durable flame retardants that can be used for natural and mixed materials at home and abroad mainly include N-methylol-3-dimethylphosphorus propionamide (Pyrovatex CP) and tetrakismethylolphosphorous chloride-urea condensation products ( Proban class) two kinds, because Proban class flame retardant is ammonia smoked fixation when processing natural fiber material, the deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com