Quaternized chitosan fibers and moisture-absorbing antibacterial wound dressing

A technology of quaternized chitosan and chitosan fiber, which is applied in the field of medical materials and can solve problems such as increased hygroscopicity, decreased wet strength of fibers or dressings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

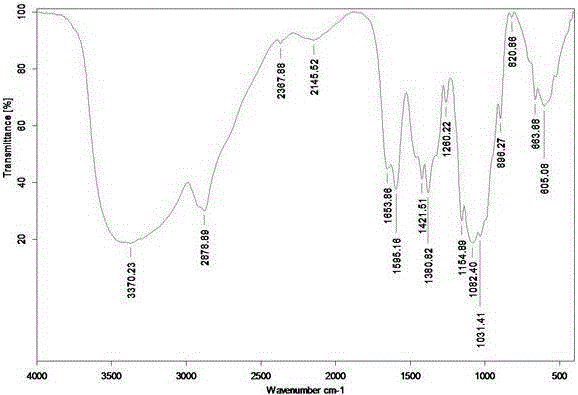

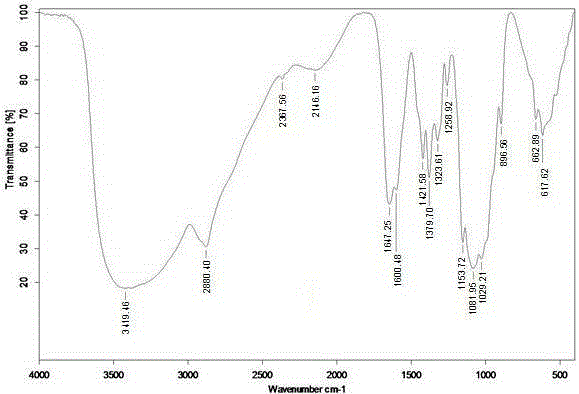

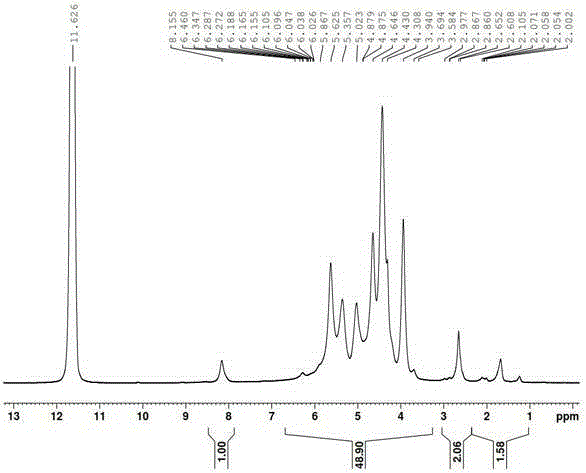

Image

Examples

preparation example Construction

[0044] The preparation of quaternized chitosan fiber is to use ordinary chitosan fiber as raw material, react with a certain proportion of 2,3-epoxypropyltrimethylammonium chloride, the polarity of the prepared fiber increases, It overcomes the disadvantages of poor hydrophilicity and non-hygroscopicity of ordinary chitosan fibers; moreover, the prepared fibers have high strength and good spinnability, and the dressings obtained have certain bactericidal ability, opening up another kind of dressing except silver-containing dressings. Antibacterial dressings, the following will introduce quaternized chitosan fibers and hygroscopic antibacterial wound dressings in combination with specific examples.

[0045] For the moisture absorption test, refer to the first part of YY / T0471.1-2004; for the antibacterial test, refer to the content of Appendix C5 of GB15979-2002.

[0046] The wet strength test is carried out according to the following method:

[0047] 1) Cut wound dressing sam...

Embodiment 1

[0054] Get 200 grams of 2,3-epoxypropyltrimethylammonium chloride, stir and dissolve with 500 milliliters of absolute alcohol, then transfer to a 1000 milliliter round-bottomed flask, add 200 grams of chitosan fiber length to the solution Tow (linear density 2.1dtex), heat and reflux at 80°C for 2 hours, take out the fiber, wash it twice in an anhydrous alcohol solution containing Tween 20, and dry it to obtain the reacted quaternized chitosan fiber.

[0055] After the above-mentioned quaternized chitosan fiber is cut into short fibers, fiber opening, carding, net laying, acupuncture, cutting and slitting, packaging and sterilization are carried out to obtain a quaternized chitosan dressing with hygroscopicity. and wet strength were 18g / 100cm 2 and 2.8N / cm.

Embodiment 2

[0057] Get 200 grams of 2,3-epoxypropyltrimethylammonium chloride, and stir and dissolve with 500 milliliters of dehydrated alcohol, then transfer in the round bottom flask of 1000 milliliters, add the chitosan fiber of 200 grams in the solution, Heat and reflux at 80° C. for 3.5 hours, take out the fibers, fully wash twice in an absolute alcohol solution containing Tween 20, and dry to obtain reacted quaternized chitosan fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Absorptive capacity | aaaaa | aaaaa |

| Absorptive capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com