Preparation method of alumina coated Li(NixCoyMn1-x-y)O2 lithium ion battery anode material

A lithium-ion battery and cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems affecting the purity and electrochemical performance of lithium-nickel-cobalt-manganese-oxygen cathode materials, and improve electrochemical cycle performance and thermal stability. The effect of reducing the generation of impurities and improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

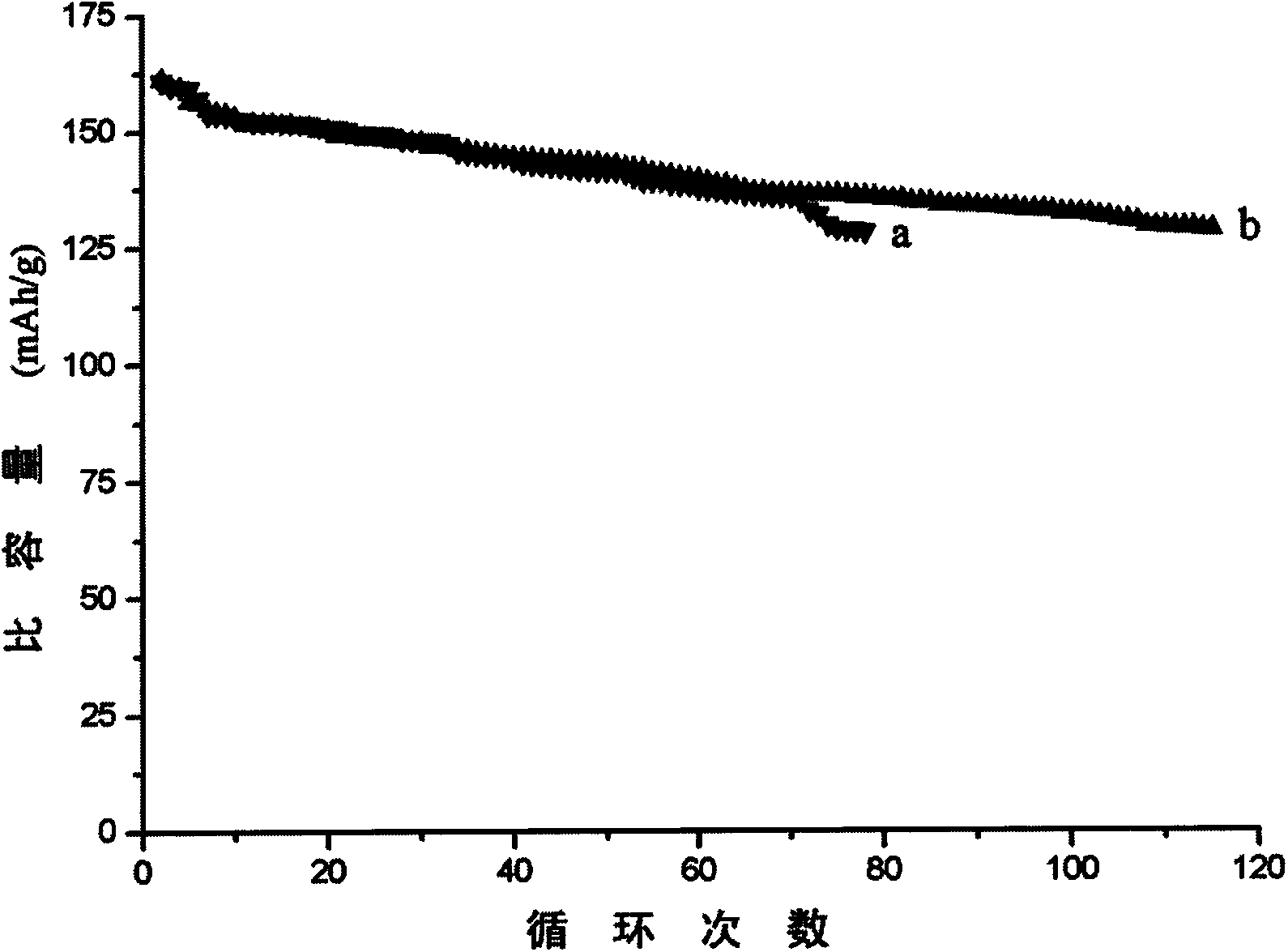

Image

Examples

Embodiment 1

[0026] (1) Nickel salt, cobalt salt and manganese salt are made into mixed salt solution A according to the molar ratio of x:y:1-x-y ratio, wherein x<1, y<1, x+y<1;

[0027] (2) Sodium hydroxide is dissolved in water to form solution B;

[0028] (3) ammoniacal liquor is dissolved in water, is made into solution C;

[0029] (4) Add solution A, solution B and solution C at the same molar ratio of 1:1:0.05 under nitrogen protection, adjust the pH to 9, and react for 5 hours at a temperature of 50°C;

[0030] (5) Aluminum isopropoxide and solution A are added to step (4) at a molar ratio of 0.1%:1, and the reaction is carried out at a temperature of 50° C. for 1 h;

[0031] (6) The product obtained in step (5) was filtered, washed and dried overnight at 100°C to obtain aluminum hydroxide modified coated Li(Ni x co y mn 1-x-y )O 2 Precursor.

[0032] (7) Aluminum hydroxide modified coated Li(Ni x co y mn 1-x-y )O 2 The precursor was fully mixed with lithium salt by wet me...

Embodiment 2

[0034] (1) Nickel salt, cobalt salt and manganese salt are made into mixed salt solution A according to the molar ratio of x:y:1-x-y ratio, wherein x<1, y<1, x+y<1;

[0035] (2) Sodium hydroxide is dissolved in water to form solution B;

[0036] (3) ammoniacal liquor is dissolved in water, is made into solution C;

[0037] (4) Add solution A, solution B and solution C at the same molar ratio of 1:1:0.3 under nitrogen protection, adjust the pH to 11, and react at a temperature of 60°C for 8 hours;

[0038] (5) Aluminum isopropoxide and solution A are added to step (4) at a molar ratio of 0.5%:1, and the reaction is carried out at a temperature of 60° C. for 3 hours;

[0039] (6) The product obtained in step (5) was filtered, washed and dried overnight at 100°C to obtain aluminum hydroxide modified coated Li(Ni x co y mn 1-x-y )O 2 Precursor.

[0040] (7) Aluminum hydroxide modified coated Li(Ni x co y mn 1-x-y )O 2 The precursor was fully mixed with lithium salt by we...

Embodiment 3

[0042] (1) Nickel salt, cobalt salt and manganese salt are made into mixed salt solution A according to the molar ratio of x:y:1-x-y ratio, wherein x<1, y<1, x+y<1;

[0043] (2) Sodium hydroxide is dissolved in water to form solution B;

[0044] (3) ammoniacal liquor is dissolved in water, is made into solution C;

[0045] (4) Add solution A, solution B and solution C at the same molar ratio of 1:1:0.5 under nitrogen protection, adjust the pH to 12, and react at a temperature of 80°C for 12 hours;

[0046] (5) adding aluminum isopropoxide and solution A to step (4) at a molar ratio of 10%:1, and reacting for 5 hours at a temperature of 80°C;

[0047] (6) The product obtained in step (5) was filtered, washed and dried overnight at 100°C to obtain aluminum hydroxide modified coated Li(Ni x coy mn 1-x-y )O 2 Precursor.

[0048] (7) Aluminum hydroxide-coated Li(Ni x co y mn 1-x-y )O 2 The precursor was fully mixed with lithium salt by wet method, and calcined in air at 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com