Composite solid polymer electrolyte membrane and preparation method and application thereof

A solid polymer, electrolyte membrane technology, applied in the field of electrochemical devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

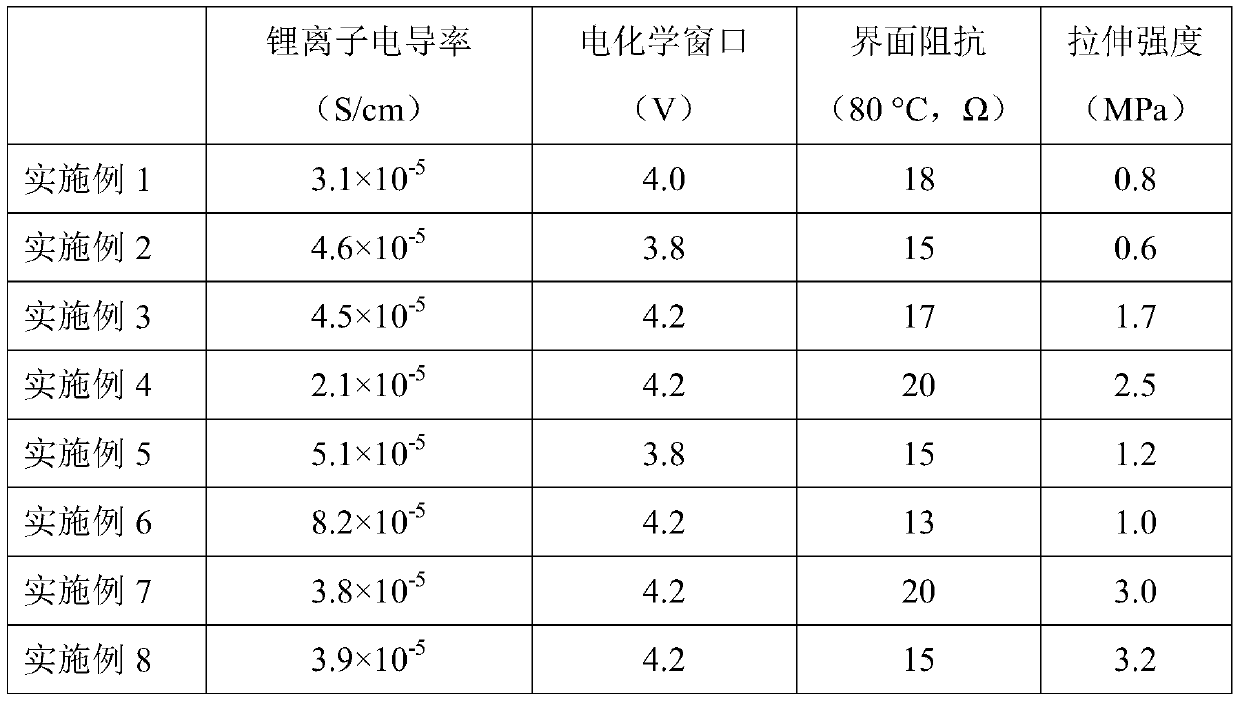

Examples

Embodiment 1

[0047] Polyethylene oxide (PEO), a lithium-ion-conducting polymer, is dissolved in an acetonitrile solution at a concentration of 8%, and a cross-linking monomer trimethylolpropane triglycidyl ether (TMPEG) and polyether with 100% of the mass of PEO are added Amine (ED900), under stirring, add N-methyl-butylpyrrolidine bistrifluoromethanesulfonic acid imide salt ionic liquid with 50% PEO mass, and finally add lithium salt LiTFSI, the addition ratio is the same as that of polymer and monomer The molar ratio of EO groups in the medium is 1:5; after mixing evenly, the solid polymer electrolyte slurry is coated on the release film, heated at 80°C, the monomers in the material are cross-linked, the solvent volatilizes, and a composite solid-state polymerization is obtained electrolyte membrane.

Embodiment 2

[0049] Polyethylene oxide (PEO), a lithium-ion-conducting polymer, was dissolved in an acetonitrile solution at a concentration of 8%, and the cross-linking monomer polypropylene glycol diglycidyl ether (DY-3601) and polyether amine with 100% of the mass of PEO were added (ED900), under stirring, add N-methyl-butylpyrrolidine bistrifluoromethanesulfonic acid imide salt ionic liquid with 50% PEO mass, and finally add lithium salt LiTFSI, and the addition ratio is the same as that in the polymer and the monomer The molar ratio of EO groups is 1:5; after mixing evenly, coat the solid polymer electrolyte slurry on the release film, heat at 100°C, cross-link the monomers in the material, and volatilize the solvent to obtain a composite solid polymer electrolyte membrane.

Embodiment 3

[0051] Polyethylene oxide (PEO), a lithium-ion-conducting polymer, was dissolved in an acetonitrile solution at a concentration of 8%, and gas-phase nano-silica (average particle size: 10nm) with a mass of 20% of PEO was added for uniform ultrasonic dispersion. Then add 100% PEO mass of cross-linking monomer trimethylolpropane triglycidyl ether (TMPEG) and polyether amine (ED900), and add N-methyl-butylpyrrolidine bistriol with 50% PEO mass Fluoromethanesulfonate imide salt ionic liquid, finally add lithium salt LiTFSI, the addition ratio is 1:5 with the molar ratio of EO groups in the polymer and the monomer; after mixing evenly, coat the solid polymer electrolyte slurry on On the release film, heating at 80°C, the monomers in the material are cross-linked, the solvent is volatilized, and a composite solid polymer electrolyte membrane is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com