Composite metallic-oxide-cladded lithium nickel cobalt manganese oxide anode material and preparation method thereof

A technology of nickel-cobalt-manganese oxides and composite metals, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as failure to meet performance requirements, limit practical applications, and low discharge specific capacity, so as to improve electrochemical cycle performance and Discharge specific capacity, large-scale industrial production, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: 30 grams of LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Add it into 150mL deionized water, and obtain a suspension under mechanical stirring; slowly add 40mL of 0.22mol / L Co(NO 3 ) 2 and 0.11mol / LAl(NO 3 ) 3 Mixed salt solution, while adding dropwise 0.3mol / L LiOH solution to keep the pH value of the suspension at 10.5; when the mixed salt solution was added dropwise, continue to stir for 30 minutes; filter the suspension, and the filter cake was Dry at 100°C for 12 hours and grind; heat up the ground powder to 400°C at a rate of 5°C / min and keep the temperature constant for 5 hours, then cool naturally to room temperature to obtain the product of the present invention.

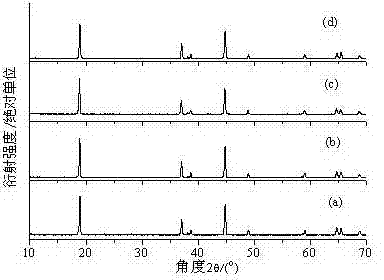

[0031] The content of metal ions Li, Ni, Co, Mn, Al in the product was measured by Japan Shimao ICPS-7500 inductively coupled plasma emission spectrometer, and Co was LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 1.73% by mass, Al as LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 0.40% of mass. X-ray powder diffractometer (Cu K ...

Embodiment 2

[0033] Embodiment 2: 40 grams of LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Add it into 100mL deionized water, and obtain a suspension under mechanical stirring; slowly add 30mL of 0.129mol / L CoSO 4 and 0.0646mol / L Al(NO 3 ) 3 Add the mixed salt solution of 0.2mol / L LiOH solution dropwise at the same time to keep the pH value of the suspension at 11; when the mixed salt solution is added dropwise, continue to stir for 60 minutes; filter the suspension and filter the cake in Dry at 120°C for 6 hours and grind; heat up the ground powder to 450°C at a rate of 2°C / min and keep the temperature constant for 5 hours, then cool naturally to room temperature to obtain the product of the present invention.

[0034] ICP and XRD ( figure 1 b) The test shows that the product is LiNi coated with cobalt-aluminum composite metal oxide 1 / 3 co 1 / 3 mn 1 / 3 o 2 , and Co is LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 0.57% by mass, Al as LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 0.13% of the mass, with a single layered structur...

Embodiment 3

[0035] Embodiment 3: 50 grams of LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Add it into 400mL deionized water, and obtain a suspension under mechanical stirring; slowly add 50mL of 0.500mol / L Co(NO 3 ) 2 and 0.250mol / L Al(NO 3 ) 3 Add the mixed salt solution of 1.0mol / L LiOH solution dropwise at the same time to keep the pH value of the suspension at 11.5. After the dropwise addition of the mixed salt solution is completed, continue to stir for 80 minutes; filter the suspension and filter the cake in Dry at 80°C for 10 hours and grind; heat up the ground powder to 500°C at a rate of 10°C / min and keep the temperature constant for 8 hours, then cool naturally to room temperature to obtain the product of the present invention.

[0036] ICP and XRD ( figure 1 d) The test shows that the product is LiNi coated with cobalt-aluminum composite metal oxide 1 / 3 co 1 / 3 mn 1 / 3 o 2 , and Co is LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 2.95% by mass, Al as LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 0.67% of the mass, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com