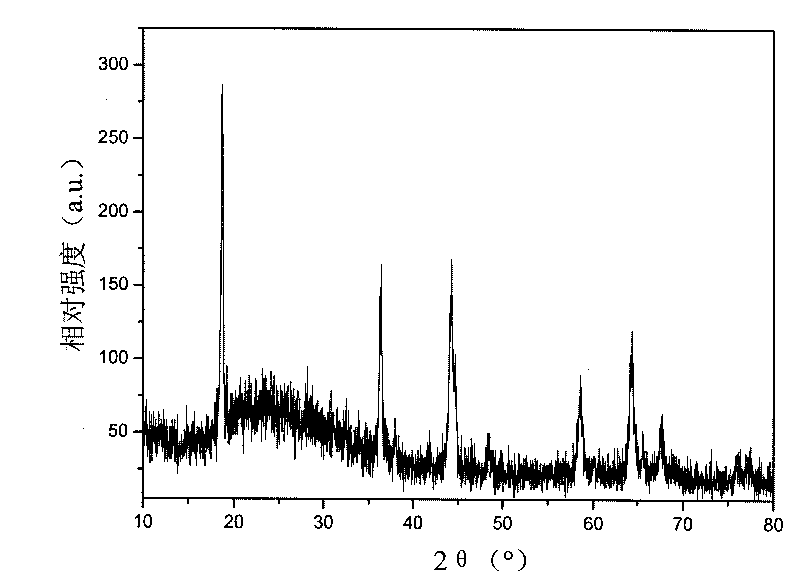

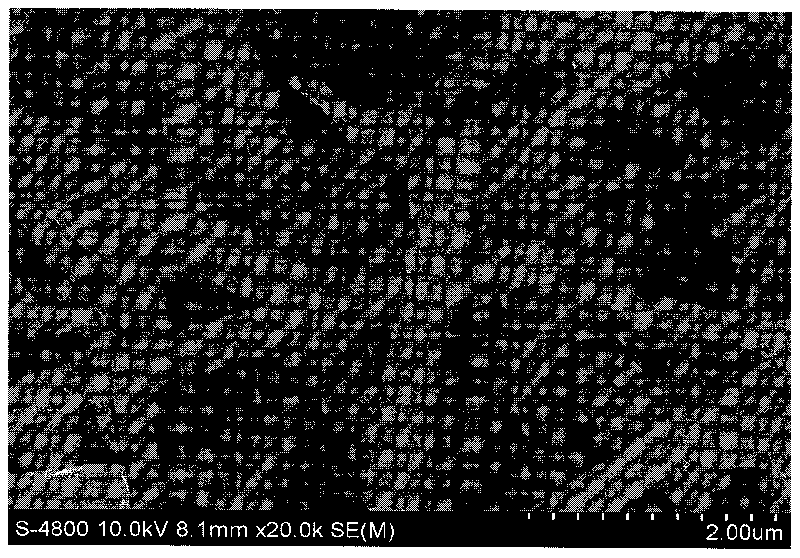

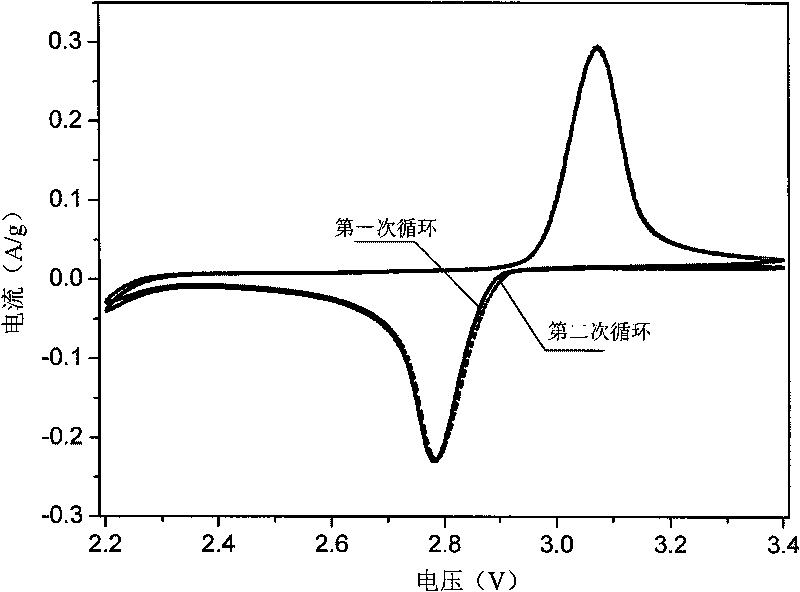

Method for synthesizing Li4Mn5O12 sub-micrometer rod

A technology of submicron rods and mixed liquids, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of less one-dimensional lithium manganate materials and complicated preparation methods, and achieve good electrochemical cycle performance and good repeatability , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (A) First, CTAB (cetyltrimethylammonium bromide) is added to deionized water, and after stirring for 10 minutes at a stirring speed of 600r / min, the first mixed solution is formed;

[0039] (B) Add MnSO to the first mixed solution 4 ·H 2 0, after stirring 5min under stirring speed 600r / min condition, form the second mixed liquor;

[0040] (C) Add KMnO to the second mixture 4 , after stirring for 5 minutes at a stirring speed of 600r / min, a brown suspension was formed;

[0041] Dosage: Add 0.8g of CTAB and 0.21g of MnSO to 100ml of deionized water 4 ·H 2 O and 1.48 g of KMnO 4 ;

[0042] (D) After incubating the brown suspension for 25 hours at a temperature of 160° C., the temperature was lowered to 25° C., and taken out to obtain a reactant having a supernatant and a lower precipitate;

[0043] (E) remove the supernatant, add alcohol to the sediment in the lower layer, stir for 10 minutes under the condition of stirring speed 600r / min, leave it for 5 minutes, an...

Embodiment 2

[0056] (A) First, CTAB (cetyltrimethylammonium bromide) was added to deionized water, and after stirring for 10 minutes at a stirring speed of 450r / min, the first mixed solution was formed;

[0057] (B) Add MnSO to the first mixed solution 4 ·H 2 0, after stirring for 5min under stirring speed 450r / min condition, form the second mixed solution;

[0058] (C) Add KMnO to the second mixture 4 , after stirring for 2 minutes at a stirring speed of 450r / min, a brown suspension was formed;

[0059] Dosage: Add 0.32g of CTAB and 0.39g of MnSO to 100ml of deionized water 4 ·H 2 O and 4.44 g of KMnO 4 ;

[0060] (D) After incubating the brown suspension for 30 hours at a temperature of 140° C., the temperature was lowered to 35° C., and taken out to obtain a reactant having a supernatant and a lower precipitate;

[0061] (E) removing the supernatant, adding alcohol to the sediment in the lower layer, stirring for 7 minutes at a stirring speed of 700 r / min, leaving it to stand for...

Embodiment 3

[0071] (A) CTAB (cetyltrimethylammonium bromide) was first added to deionized water, and after stirring for 5 minutes at a stirring speed of 700r / min, the first mixed solution was formed;

[0072] (B) Add MnSO to the first mixed solution 4 ·H 2 0, after stirring for 10min under stirring speed 700r / min condition, form the second mixed solution;

[0073] (C) Add KMnO to the second mixture 4 , after stirring for 2 minutes at a stirring speed of 700r / min, a brown suspension was formed;

[0074] Dosage: Add 0.94g of CTAB and 0.13g of MnSO to 100ml of deionized water 4 ·H 2 O and 1.48 g of KMnO 4 ;

[0075] (D) After incubating the brown suspension for 12 hours at a temperature of 180° C., the temperature was lowered to 25° C., and taken out to obtain a reactant having a supernatant and a lower precipitate;

[0076] (E) remove the supernatant, add alcohol to the sediment in the lower layer, stir for 5 minutes at a stirring speed of 450 r / min, leave it for 2 minutes, and remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com