Method for recycling valuable metals of waste lithium ion battery and regenerating ternary positive electrode material

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of recycling valuable metals in waste lithium-ion batteries and regenerated ternary positive electrode materials. It can solve the problems of long high-temperature treatment time, low purity of recycled materials, and a large number of chemical reagents to achieve recycling. Low cost, safe and easy to obtain, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

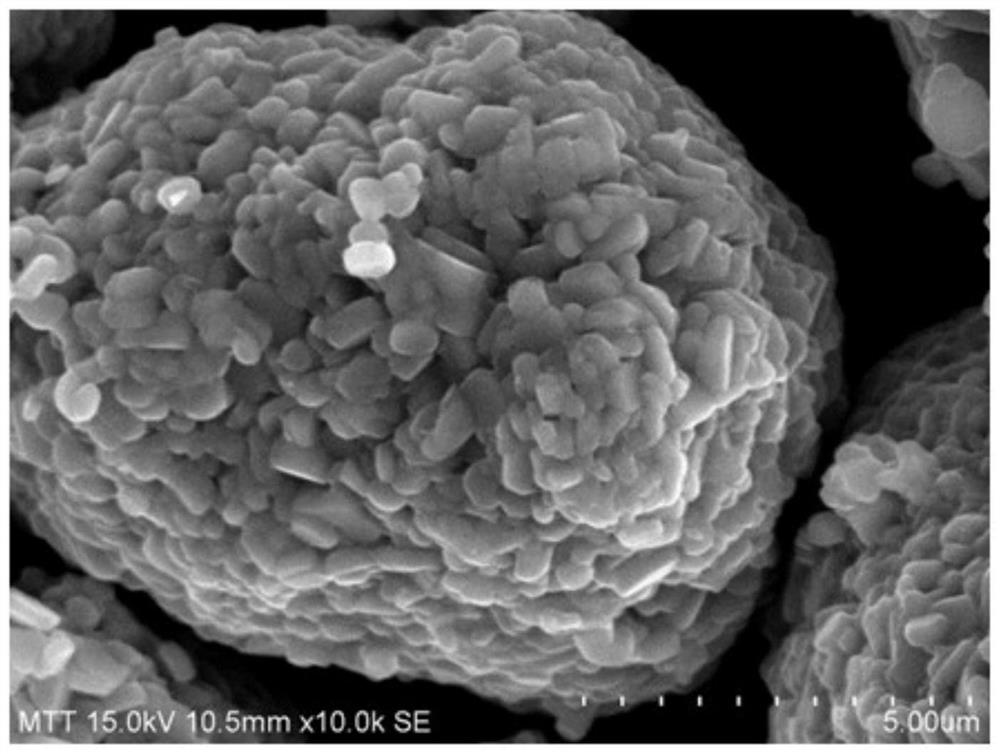

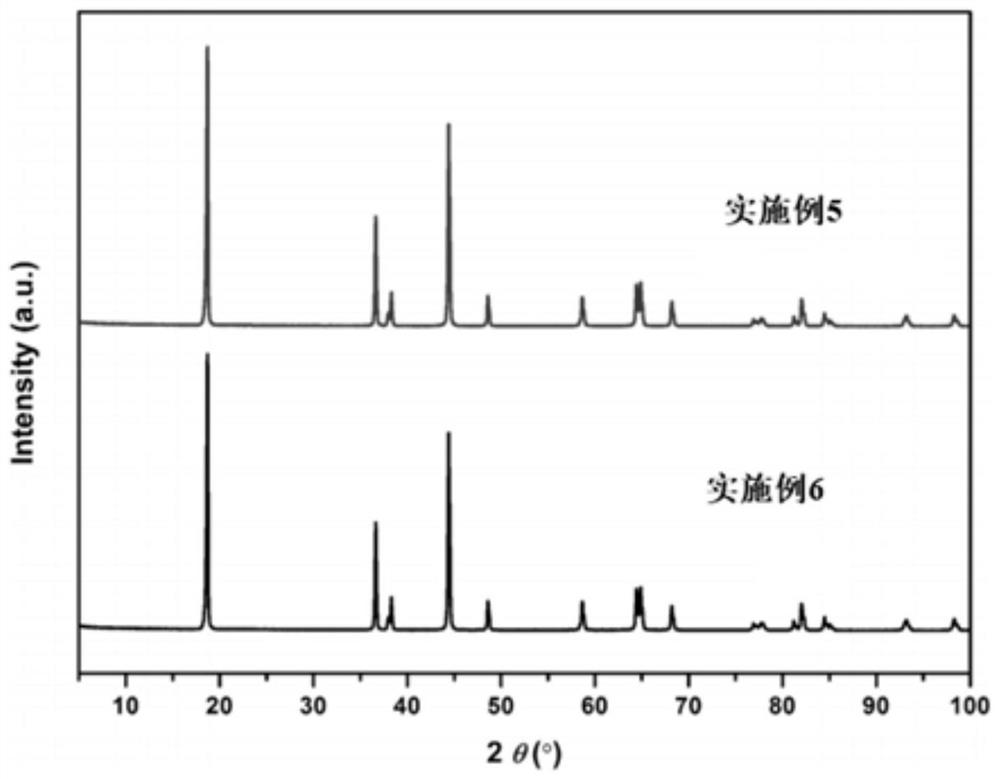

Image

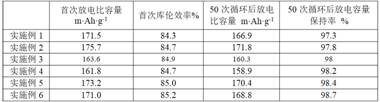

Examples

Embodiment 1

[0046] Discharge, disassemble, and remove impurities from the waste nickel-cobalt lithium manganate ternary battery to obtain the positive electrode sheet, put the positive electrode sheet in a muffle furnace at 700°C for 2 hours, and remove the conductive agent and binder in the positive electrode sheet to obtain the waste tertiary battery. Yuan cathode material. Weigh 50g of waste and old ternary positive electrode material and place it in a 500ml beaker, add water to adjust the mass volume ratio of positive electrode material to water to be 1:5, then add acetic acid with a molar concentration of 2mol / L, and the reducing agent sodium thiosulfate with a molar concentration of 1mol / L L, the above mixed solution was reacted at 80° C. for 4 hours under magnetic stirring, and filtered to obtain a filtrate rich in valuable metal ions. The content of lithium ions and transition metal ions (nickel ions, cobalt ions, manganese ions) in the filtrate is determined by ICP-OES, and the m...

Embodiment 2

[0048] Discharge, disassemble, and remove impurities from the waste nickel-cobalt lithium manganate ternary battery to obtain the positive electrode sheet, put the positive electrode sheet in a muffle furnace at 600°C for 4 hours, and remove the conductive agent and binder in the positive electrode sheet to obtain the waste tertiary battery. Yuan cathode material. Weigh 30 g of the waste ternary positive electrode material and place it in a 500ml beaker, add water to adjust the mass volume ratio of the positive electrode material to water to be 1:3, then add maleic acid with a molar concentration of 2mol / L, and the reducing agent hydrazine hydrate with a molar concentration of 1mol / L L, the above mixed solution was reacted at 80° C. for 4 hours under magnetic stirring, and filtered to obtain a filtrate rich in valuable metal ions. The content of lithium ions and transition metal ions (nickel ions, cobalt ions, manganese ions) in the filtrate is determined by ICP-OES. According...

Embodiment 3

[0050] Discharge, disassemble, and remove impurities from the waste nickel-cobalt lithium manganate ternary battery to obtain the positive electrode sheet, put the positive electrode sheet in a muffle furnace at 600°C for 4 hours, and remove the conductive agent and binder in the positive electrode sheet to obtain the waste tertiary battery. Yuan cathode material. Weigh 50 g of the waste ternary positive electrode material and place it in a 500ml beaker, add water to adjust the mass volume ratio of the positive electrode material to water to be 1:3, then add maleic acid with a molar concentration of 2mol / L, and the reducing agent hydrazine hydrate with a molar concentration of 1mol / L L, the above mixed solution was reacted at 80° C. for 4 hours under magnetic stirring, and filtered to obtain a filtrate rich in valuable metal ions. Determine the content of lithium ions and transition metal ions (nickel ions, cobalt ions, manganese ions) in the filtrate by ICP-OES, according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com