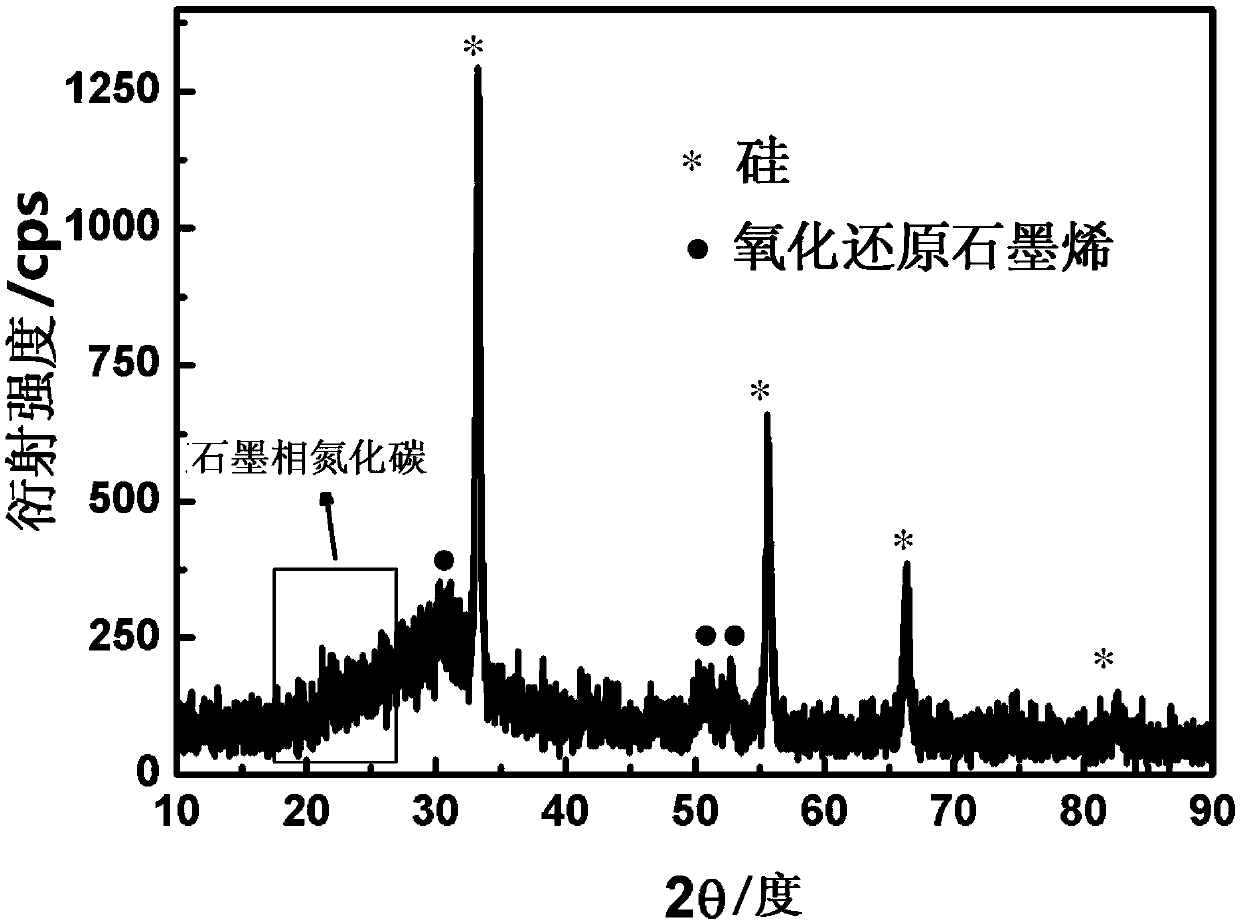

Silicon embedded redox graphene/graphite phase carbon nitride composite material, preparation and application thereof

A technology of graphitic carbon nitride and composite materials, applied in the field of lithium ion batteries, can solve the problems of increasing graphene/carbon nitride sheet spacing, poor chemical stability, separation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

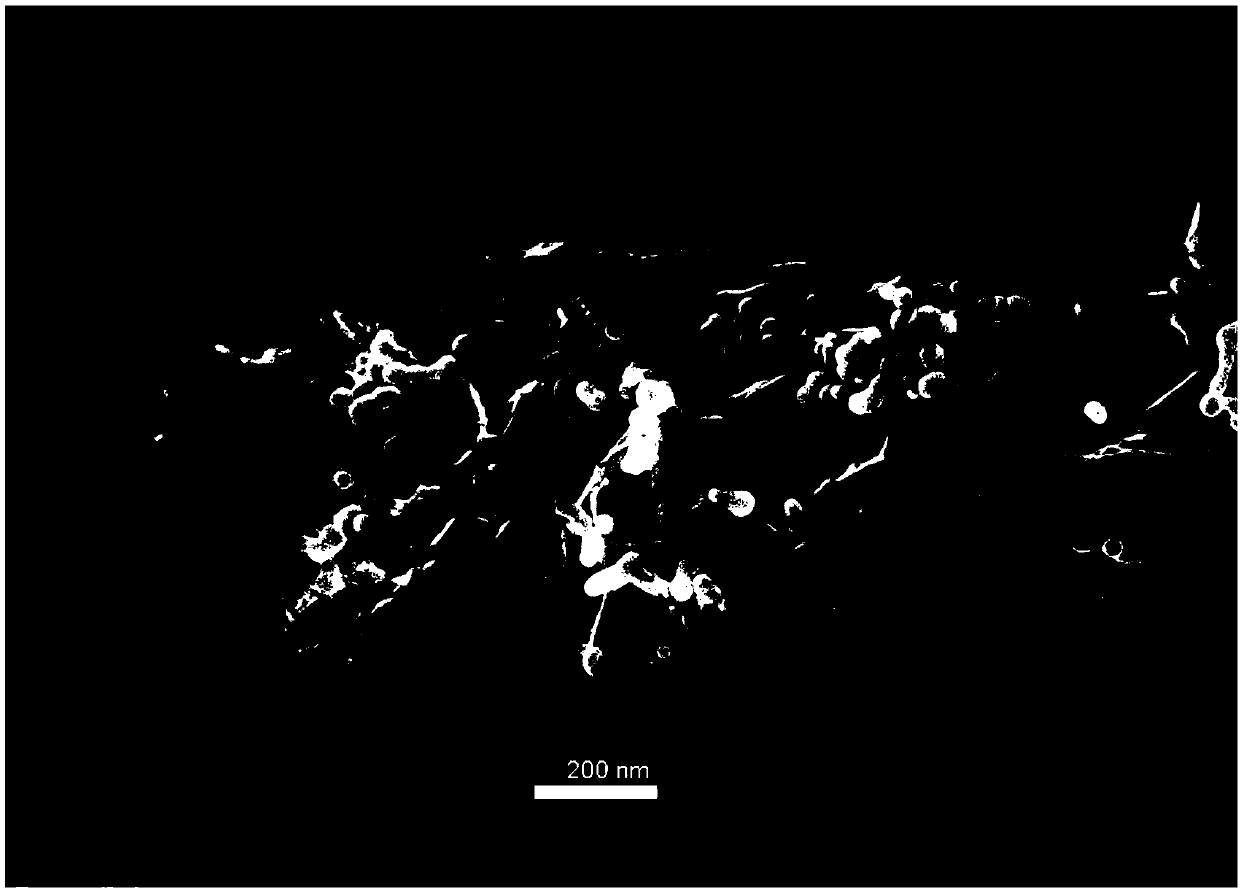

[0045] A method for preparing a silicon-embedded redox graphene / graphite phase carbon nitride composite material comprises the following steps:

[0046] S1. Add 5 g of urea and 0.5 g of graphene oxide into 100 mL of alcohol / water mixed solution (the volume ratio of ethanol: water is 1:2), and stir until all the liquid is volatilized to obtain a uniform mixture of urea / graphene oxide;

[0047] S2. Move the mixture of 5.5 g of urea / graphene oxide obtained in step S1 into a tube furnace fed with argon / hydrogen standard gas, raise the temperature to 550° C. at a heating rate of 10° C. / min, and heat it for 2 hours. Cool to room temperature, the product obtained by the reaction is redox graphene / graphite phase carbon nitride composite matrix;

[0048] S3, adding 0.1g of dodecyltrimethylammonium bromide to 200mL of deionized water, and configuring dodecyltrimethylammonium bromide / water mixed solution (0.5g / L) for subsequent use;

[0049] S4, 2.0g silicon powder (average particle siz...

Embodiment 2

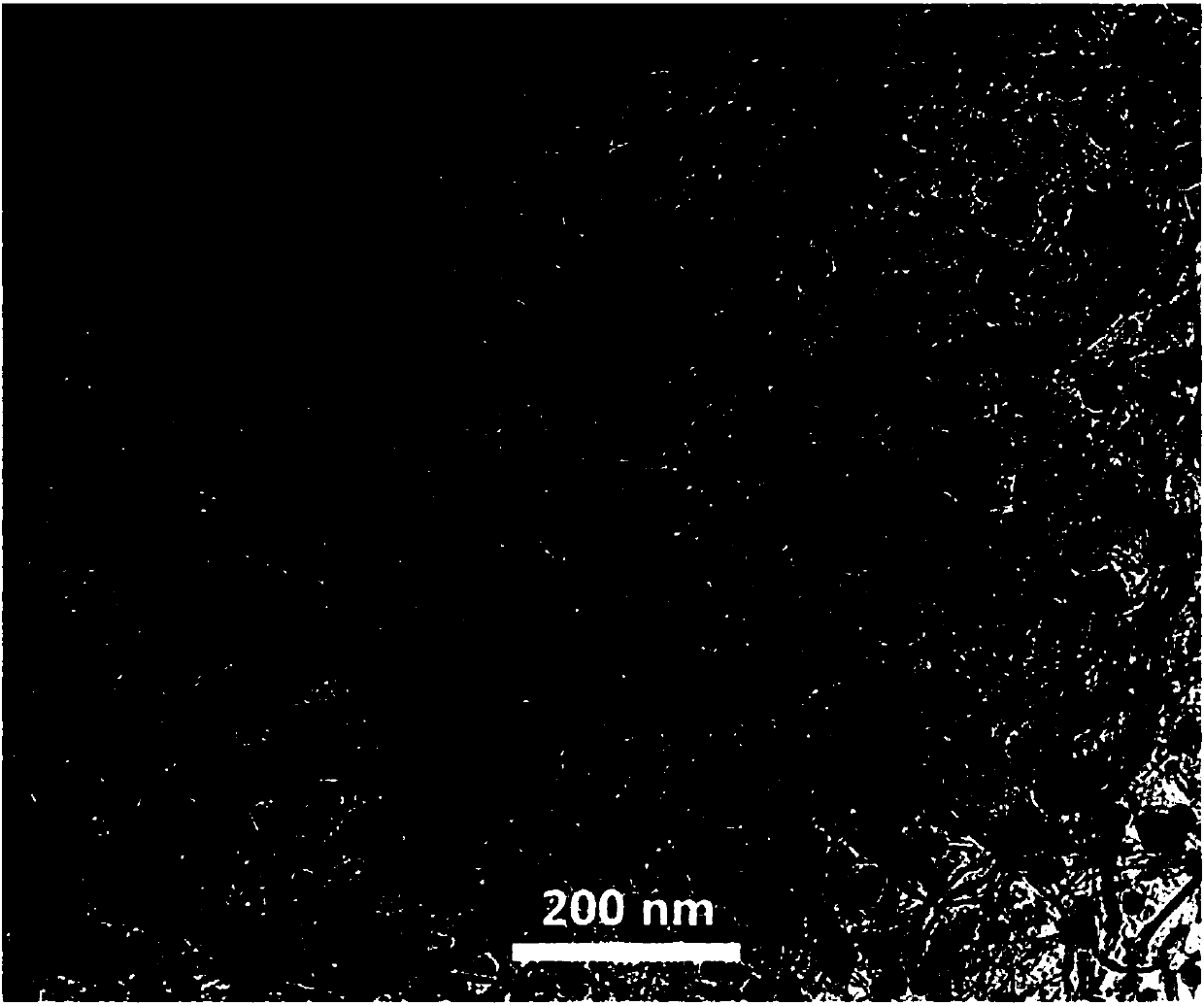

[0057] A method for preparing a silicon-embedded redox graphene / graphite phase carbon nitride composite material comprises the following steps:

[0058] S1. Add 5g of urea and 0.5g of graphene oxide into 50mL of alcohol / water mixed solution (volume ratio of ethanol: water is 1:1), and stir until all the liquid is volatilized to obtain a uniform mixture of urea / graphene oxide;

[0059] S2. Move the 5.5g urea / graphene oxide mixture obtained in step S1 into a tube furnace fed with argon / hydrogen standard gas, raise the temperature to 650°C at a heating rate of 20°C / min, and heat it for 0.5 hours. Cool to room temperature, the product obtained by the reaction is redox graphene / graphite phase carbon nitride composite matrix;

[0060] S3, adding 0.2g of dodecyltrimethylammonium bromide to 200mL of deionized water, and configuring dodecyltrimethylammonium bromide / water mixed solution (1.0g / L) for subsequent use;

[0061] S4, 0.7g silicon powder (average particle size is 40nm) is add...

Embodiment 3

[0066] A method for preparing a silicon-embedded redox graphene / graphite phase carbon nitride composite material comprises the following steps:

[0067] S1. Add 10g of urea and 0.4g of graphene oxide into 50mL of alcohol / water mixed solution (the volume ratio of ethanol:water is 1:4), and stir until all the liquid is volatilized to obtain a uniform mixture of urea / graphene oxide;

[0068] S2. Move the 10.4g urea / graphene oxide mixture obtained in step (1) into a tube furnace fed with argon / hydrogen standard gas, heat up to 650°C at a heating rate of 2°C / min, and keep it warm for 4 hours , furnace cooled to room temperature. The product obtained by the reaction is the redox graphene / graphite phase carbon nitride composite material.

[0069] S3. Add 0.02 g of polydiallyldimethylammonium chloride into 200 mL of deionized water, and prepare a polydiallyldimethylammonium chloride / water mixed solution (0.1 g / L) for later use.

[0070] S4, 1.0g silicon powder (average particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com