Preparation method of layered cobalt aluminium bihydroxy composite metal oxide electrode material

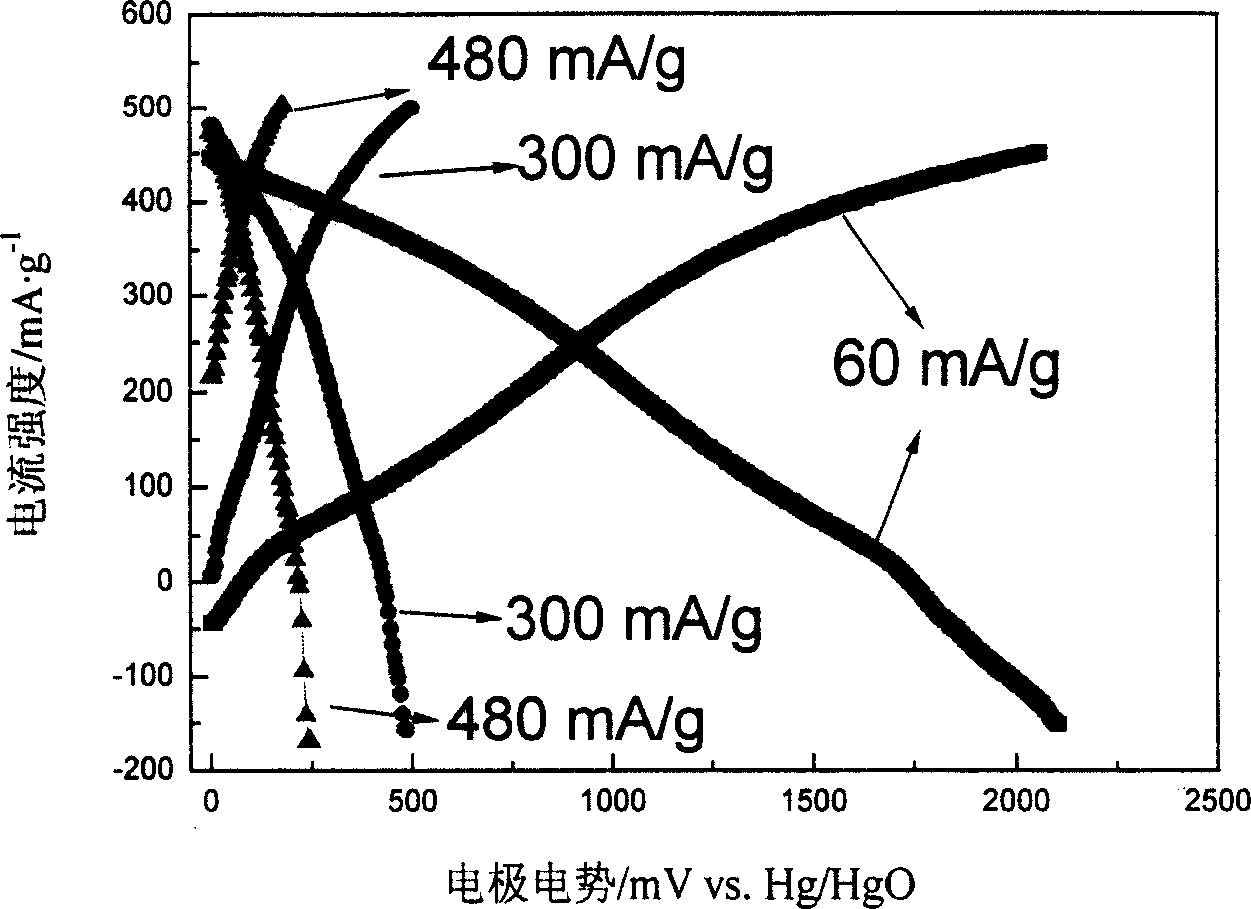

A technology of bis-hydroxyl compound and electrode material, applied in electrode manufacturing, hybrid capacitor electrode, capacitor manufacturing, etc., can solve the problems of underutilization of active substances, agglomeration between particles, insufficient crystal form, etc., and achieve electrochemical cycle. Good performance, good rate characteristics, uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

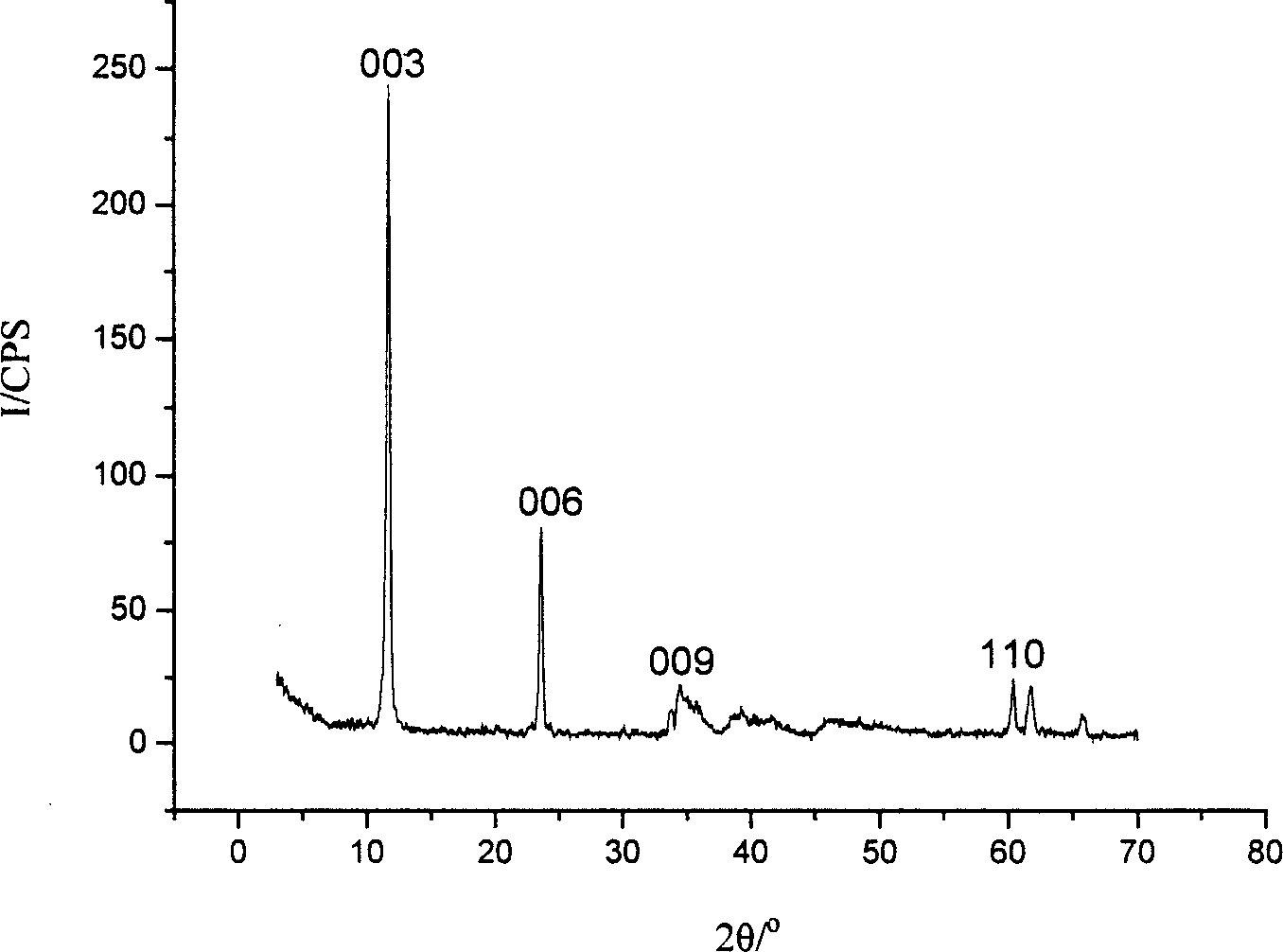

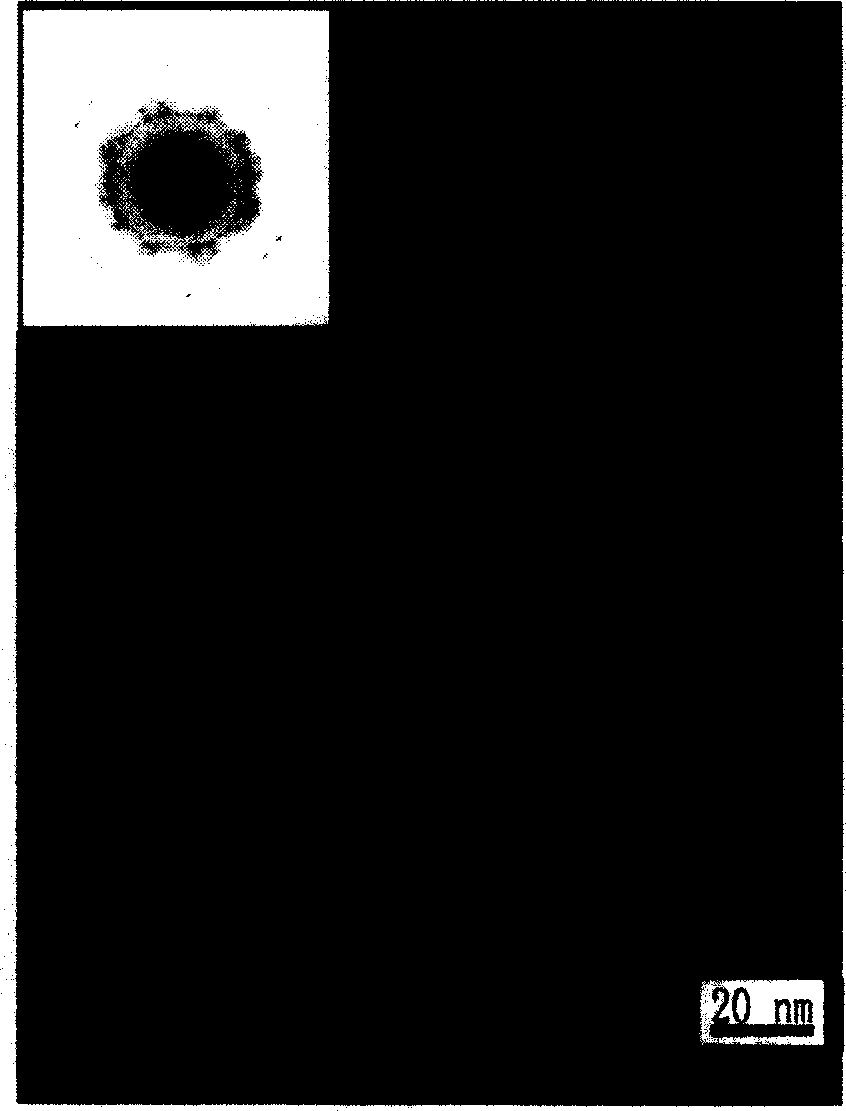

Embodiment 1

[0027] Take 0.10mol of Co(NO 3 ) 2 and 0.05mol of Al(NO 3 ) 3 Dissolve in 150ml of deionized water to make a mixed salt solution, take 0.20mol of NaOH and 0.10mol of NaOH 2 CO 3Dissolve in 150ml of deionized water to make an alkaline solution; add the mixed salt solution and alkaline solution to the full back-mixed liquid film reactor at the same time at the same time, and mix them fully in the gap between the rotor and the stator after being dispersed by the liquid distributor , discharged from the discharge port, the rotor speed is controlled to be 4000rmp, the reaction temperature is 25°C, and the residence time of the material in the reactor is 2min; Stir and crystallize in a water bath for 10 hours; wash the crystallized substance with deionized water several times, filter until the pH value is less than 8, and then dry it in vacuum at 80°C for 5h; dry the dried substance at 2°C·min -1 The temperature was raised to 160°C for 5 hours at a constant temperature, and the...

Embodiment 2

[0029] Take 0.20mol of CoSO 4 and 0.025mol of Al 2 (SO 4 ) 3 Dissolve in 150ml of deionized water to make a mixed salt solution, take 0.20mol of NaOH and 0.10mol of NaOH 2 CO 3 Dissolve in 150ml of deionized water to make an alkaline solution; add the mixed salt solution and alkaline solution to the full back-mixed liquid film reactor at the same time at the same time, and mix them fully in the gap between the rotor and the stator after being dispersed by the liquid distributor , discharged from the discharge port, the rotor speed is controlled to be 3500rmp, the reaction temperature is 35°C, and the residence time of the material in the reactor is 1min; Stir and crystallize in a water bath for 15 hours; wash the crystallized substance with deionized water several times, filter until the pH value is less than 8, and then dry it in vacuum at 70°C for 5h; dry the dried substance at 2°C·min -1 The rate is raised to 200°C for 5 hours of constant temperature roasting, and then...

Embodiment 3

[0031] Take 0.15mol of CoCl 2 and 0.05mol of AlCl 3 Dissolve in 150ml of deionized water to make a mixed salt solution, take 0.15mol of NaOH and 0.10mol of NaOH 2 CO 3 Dissolve in 150ml of deionized water to make an alkaline solution; add the mixed salt solution and alkaline solution to the full back-mixed liquid film reactor at the same time at the same time, and mix them fully in the gap between the rotor and the stator after being dispersed by the liquid distributor , discharged from the discharge port, the rotor speed is controlled to be 5000rmp, the reaction temperature is 25°C, and the residence time of the material in the reactor is 3min; Stir and crystallize in a water bath for 15 hours; wash the crystallized substance with deionized water several times, filter until the pH value is less than 8, and then dry it in vacuum at 80°C for 10h; dry the dried substance at 5°C·min -1 The temperature was raised to 160°C for 5 hours at a constant temperature, and then cooled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com