Tensile conductive cable and manufacturing method thereof

A technology of cables and conductive fillers, which is applied in the field of preparation of flexible and stretchable conductive composite materials, can solve the problems of high resistance of stretchable conductive materials, and achieve the effect of simple process and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

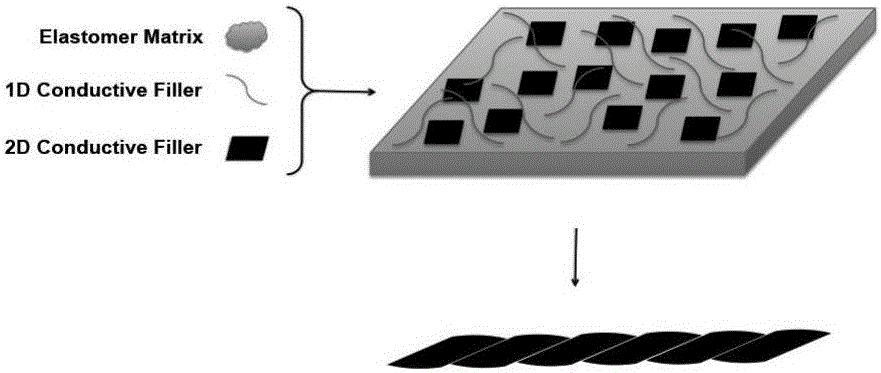

[0020] Embodiment 1: the preparation of material

[0021] (1) Take the following materials according to volume percentage: 80% of SEBS elastomer, 15% of copper nanosheets coated with silver, and 5% of carbon nanotubes;

[0022] (2) Use N,N-dimethylformamide as solvent to prepare SEBS solution and conductive filler dispersion respectively, mix the two evenly and then pour them into ethanol for flocculation, after filtering, drying and pelletizing Obtain the conductive composite material masterbatch;

[0023] (3) The obtained composite material masterbatch is hot-pressed at 200°C and 10MPa to form a film, and the film thickness is controlled by using different molds;

[0024] (4) Cut the obtained composite material film into strips with a width of 2mm, fix one end thereof, connect the other end to a motor to rotate around an axis, and twist to form a line. The number of rotations of the motor is controlled so that the strip of composite material shrinks by 20% in its length di...

Embodiment 2

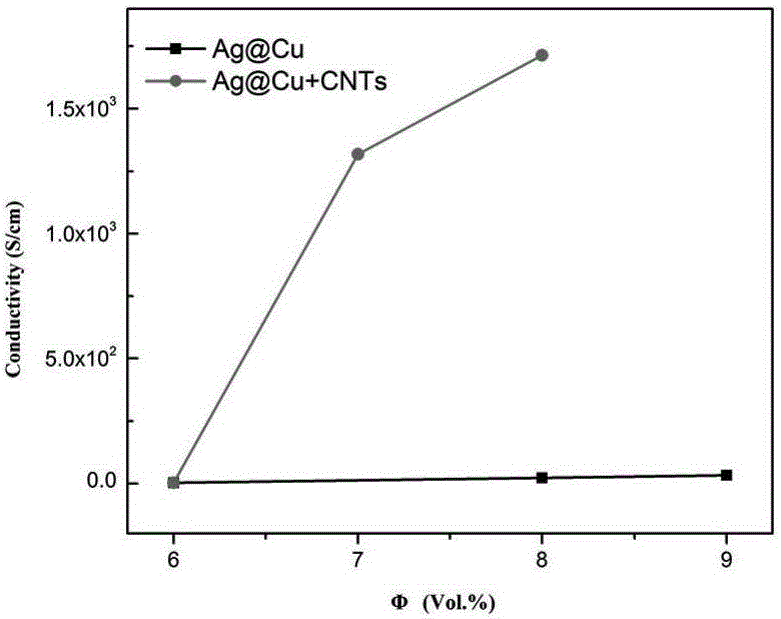

[0025] Example 2: Conductivity Test of Stretchable Cables Containing Different Volume Fractions of Conductive Fillers

[0026] For the stretchable conductive cables containing different volume fractions of conductive fillers prepared according to the test method described in Example 1, the volume conductivity was tested respectively, and the typical results are shown in the attached figure 2 Shown: The lower curve represents the binary composite system in which the conductive filler is only silver-coated copper nanosheets. It can be seen that as the filler content increases, the conductivity of the stretchable wire increases gradually; the upper curve represents the conductive filler is silver For the ternary composite system of copper-coated nanosheets and carbon nanotubes, it can be seen that when the total volume of the conductive filler is the same, the conductivity of the ternary composite system is higher than that of the binary composite system. The measured volume con...

Embodiment 3

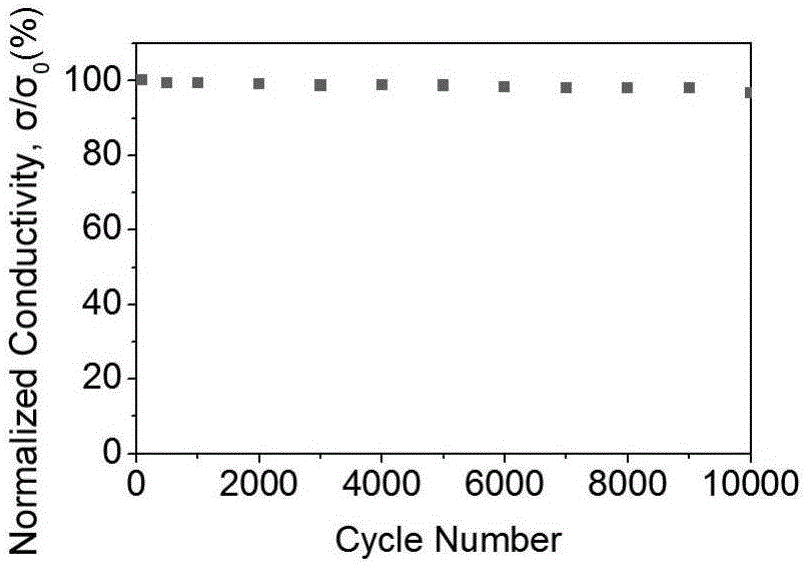

[0027] Example 3: Testing the Influence of Alternate Stretch and Release Cycles on Conductivity of Stretchable Conductive Cables

[0028] The stretchable conductive cable prepared according to the method described in Example 1 was uniaxially stretched to 100% strain, and then the tensile force was released to make the elastic conductive cable retract to the initial test length, and its conductivity was tested. Repeat the stretching and release experiments 10,000 times, and the results of the impact of the cycle test on the conductivity are shown in the attached image 3 , After 10,000 cycles of stretching and release, the change in conductance is less than 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bulk conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com