Metal cation doped cobalt polysulfide/cobalt hydroxide composite material and preparation method and application thereof

A metal cation, cobalt hydroxide technology, applied in metal material coating process, hybrid/electric double layer capacitor manufacturing, nanotechnology for materials and surface science, etc. Simple, short time-consuming, high specific capacitance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

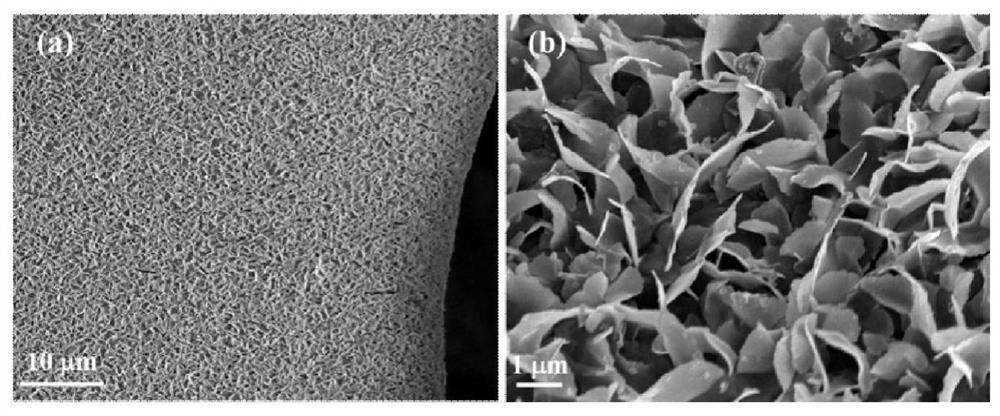

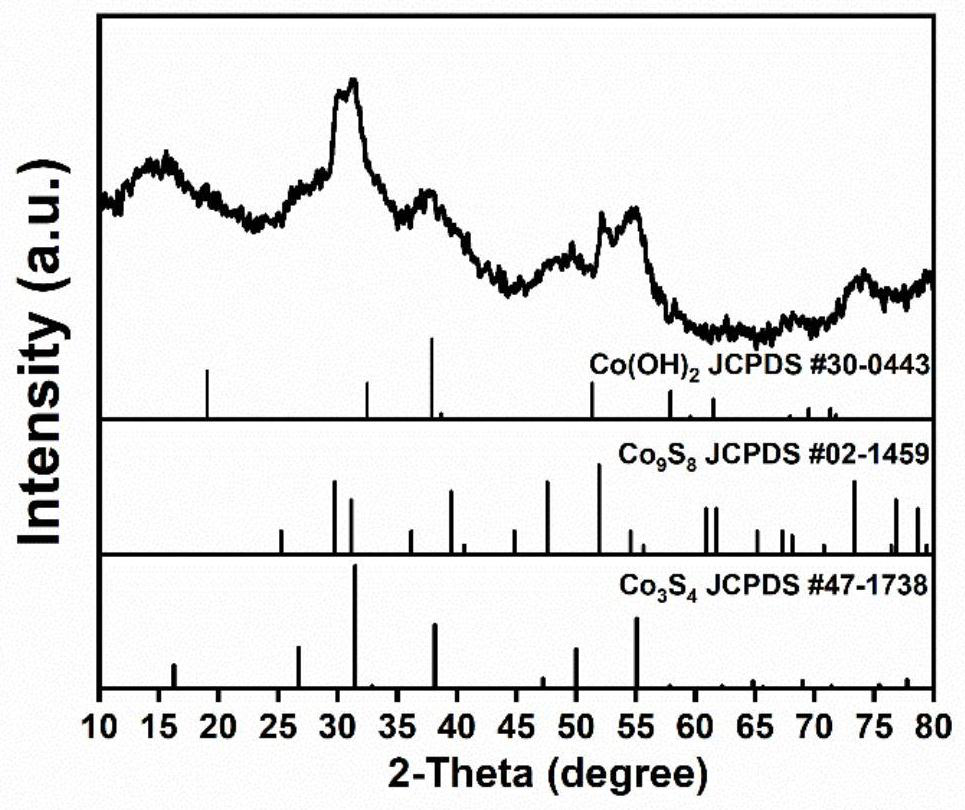

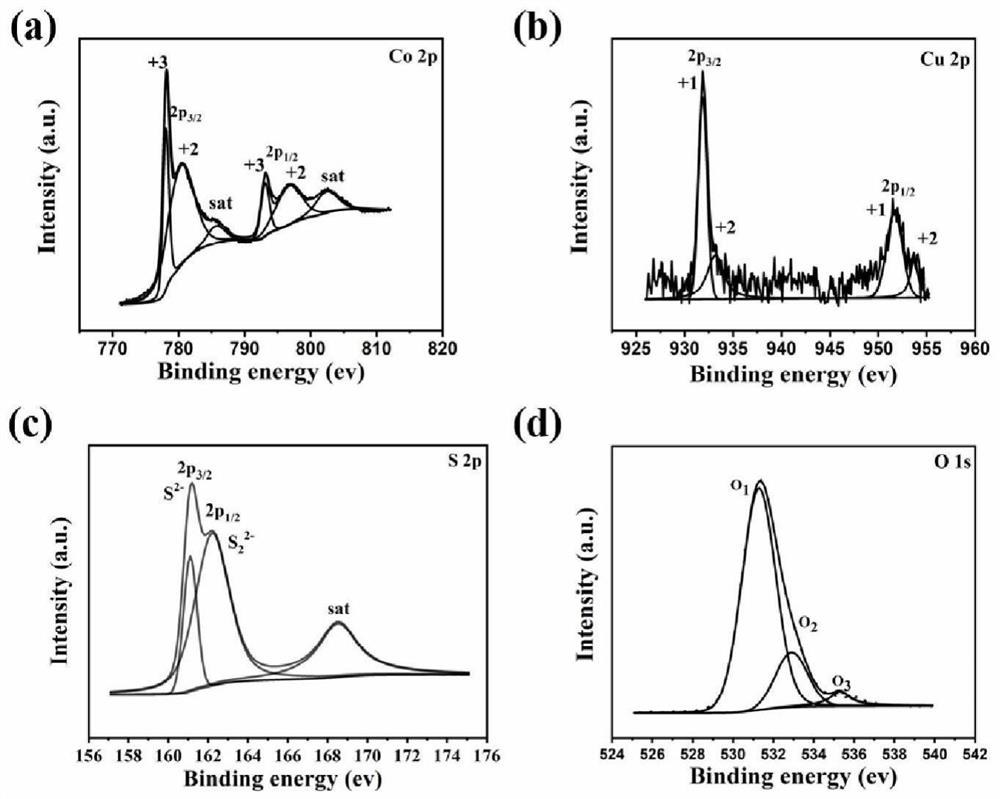

[0039] Example 1: Cu@CoS x / Co(OH) 2 Preparation of nanosheets and their application to supercapacitor electrode materials

[0040] When the doped metal cation is copper, its preparation steps are:

[0041] Take 0.409g (1.4mmol) Co(NO 3 ) 2 ·6H 2 O, 0.028g (0.12mmol) Cu(NO 3 ) 2 ·3H 2 O was dissolved in 30mL methanol, 0.3g (3mmol) dimethylimidazole was dissolved in 10mL methanol, the two were mixed evenly, and the solution was transferred to a 50mL hydrothermal kettle; the pretreated 4×1cm foamed nickel substrate was added, and The reaction was carried out at 120° C. for 2 hours. After the reaction was completed, it was naturally cooled to room temperature, and the nickel foam substrate was taken out, rinsed several times with deionized water and absolute ethanol, and vacuum-dried at 60°C for 12 hours to obtain Cu@Co / NF-Pre.

[0042] Take 0.6g (2.5mmol) Na 2 S·9H 2 O was dissolved in 40 mL of water, Cu@Co / NF-Pre was added, and reacted at 140 °C for 2 hours. After t...

Embodiment 2

[0051] Example 2: Zn@CoSx / Co(OH) 2 Preparation of nanosheets and their application to supercapacitor electrode materials

[0052] When the metal cation of doping is zinc, its preparation steps are:

[0053] Take 0.412g (1.4mmol) Co(NO 3 ) 2 ·6H 2 O, 0.035g (0.12mmol) Zn (NO 3 ) 2 ·6H 2 O was dissolved in 30mL ethanol, 0.5g (3mmol) terephthalic acid was dissolved in 10mL ethanol, the two were mixed evenly, and the solution was transferred to a 50mL hydrothermal kettle; the pretreated 4×1cm foamed nickel substrate was added, and The reaction was carried out at 120° C. for 4 hours. After the reaction was completed, it was naturally cooled to room temperature, and the nickel foam substrate was taken out, rinsed several times with deionized water and absolute ethanol, and vacuum-dried at 60°C for 12 hours to obtain Zn@Co / NF-Pre.

[0054] Take 0.6g Na 2 S·9H 2 O (2.5mmol) was dissolved in 40mL of water, Zn@Co / NF-Pre was added, and the reaction was carried out at 140°C for ...

Embodiment 3

[0059] Example 3: Mn@CoSx / Co(OH) 2 Preparation of nanosheets and their application to supercapacitor electrode materials

[0060] When the metal cation of doping is manganese, its preparation steps are:

[0061] Take 0.400g (1.4mmol) Co(NO 3 ) 2 ·6H 2 O, 0.030g (0.12mmol) Mn(NO 3 ) 2 4H 2 Dissolve O in 30mL N,N-dimethylformamide, take 0.5g (3mmol) phthalic acid and dissolve it in 10mL N,N-dimethylformamide, mix the two evenly and transfer the solution to a 50mL hydrothermal kettle ; Add the pretreated 4×1cm foam nickel substrate, and react at 120°C for 6 hours. After the reaction was completed, it was naturally cooled to room temperature, and the nickel foam substrate was taken out, rinsed several times with deionized water and absolute ethanol, and vacuum-dried at 60°C for 12 hours to obtain Mn@Co / NF-Pre.

[0062] Take 0.6g Na 2 S·9H 2 O (2.5mmol) was dissolved in 40mL of water, Mn@Co / NF-Pre was added, and the reaction was carried out at 140°C for 4 hours. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com