Carbon nanotube three-dimensional network architecture and polymer composite material thereof, and preparation methods thereof

A carbon nanotube and three-dimensional network technology, applied in the field of preparation of functional composite materials, can solve the problems of high cost and inability to popularize mass production, and achieve the effects of low cost, novel preparation ideas and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation of the carbon nanotube three-dimensional network macroscopic body comprises the following steps:

[0043] Step 1. Add deionized water to the carbon nanotube aqueous dispersion, and perform ultrasonic dispersion for 30 minutes, so that the carbon nanotubes are uniformly dispersed in water to obtain a carbon nanotube dispersion; the carbon nanotube content in the carbon nanotube dispersion is 1wt.%. . ;

[0044] Step 2. Pour the above-mentioned carbon nanotube dispersion into a polypropylene plastic tube with a diameter of 1.5 cm and a height of 8 cm, and gradually immerse the plastic tube in liquid nitrogen at a speed of 6 mm / min until the dispersion is completely frozen into ice;

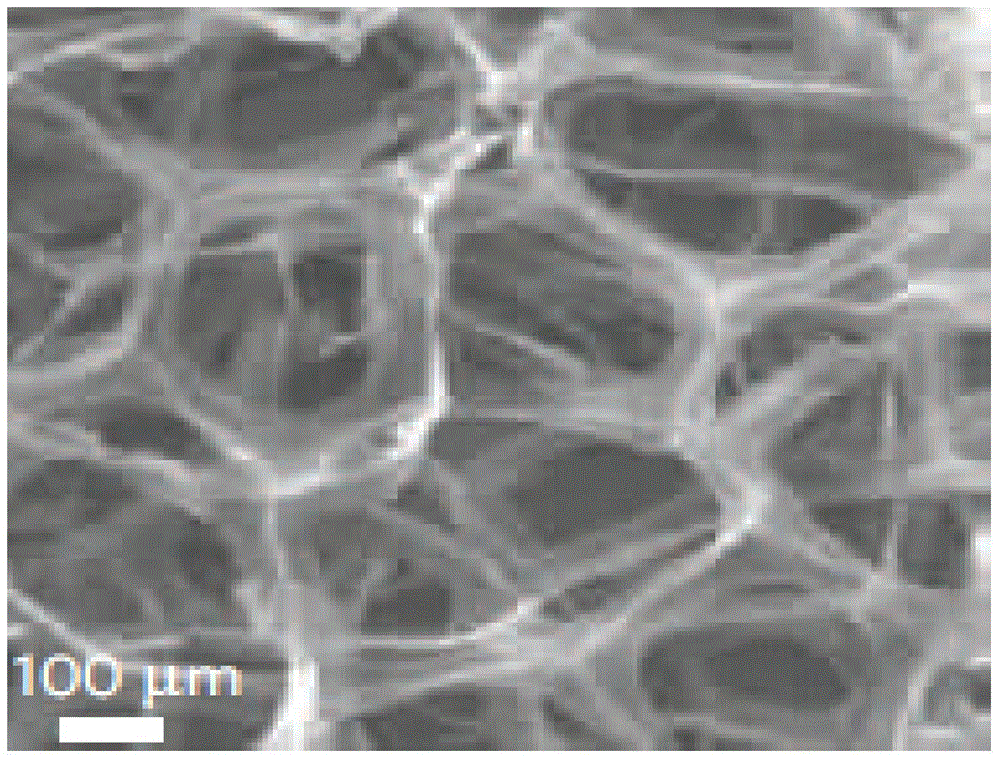

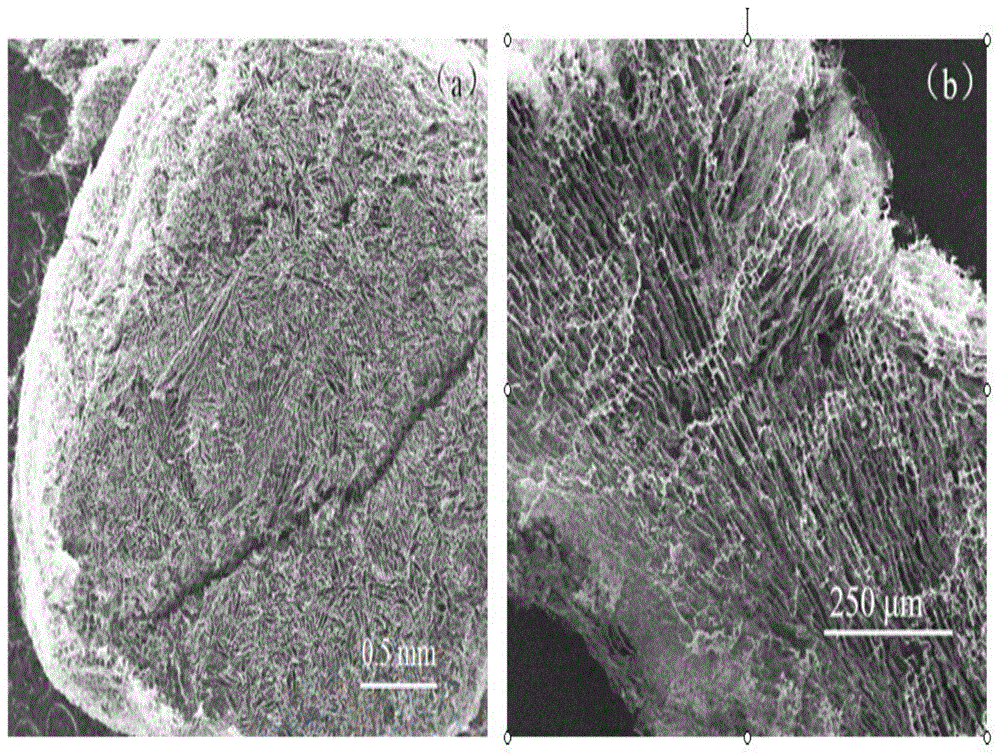

[0045] Step 3, put the above-mentioned frozen ice and the mold together into a freeze dryer and freeze-dry for 48 hours until the ice is completely sublimated to obtain a three-dimensional network macroscopic body of carbon nanotubes, such as figure 1 As shown, the scanning ...

Embodiment 2

[0047] The preparation method of carbon nanotube / bisphenol F epoxy resin composite material with three-dimensional continuous skeleton structure:

[0048] 1. Preparation of bisphenol F epoxy resin precursor: weigh 20g of bisphenol F epoxy resin (NPEF-170) and 6g of diaminodiphenylmethane (DDM) curing agent, mix the two, and vigorously Stir for about 10 minutes until uniformly mixed, and then remove air bubbles in a vacuum environment for 5 minutes to obtain a bisphenol F epoxy resin precursor;

[0049] 2. Mixing: Put the carbon nanotube macroscopic body prepared in Example 1 into the mold, and then drop the above-mentioned bisphenol F epoxy resin precursor solution at 80°C according to the volume ratio of 1:1 to make it penetrate and fully infiltrate Carbon nanotube macroscopic body, a mixture;

[0050] 3. Vacuum treatment: Vacuum the above mixture for 2 hours to remove the air bubbles, so that the resin precursor can be better filled into the pores of the carbon nanotube net...

Embodiment 3

[0054] The preparation of the carbon nanotube three-dimensional network macroscopic body comprises the following steps:

[0055] Step 1. Add deionized water to the carbon nanotube aqueous dispersion, and perform ultrasonic dispersion for 30 minutes, so that the carbon nanotubes are uniformly dispersed in water to obtain a carbon nanotube dispersion; the carbon nanotube content in the carbon nanotube dispersion is 3wt.%. .

[0056] Step 2. Pour the above-mentioned carbon nanotube dispersion into a polypropylene plastic tube with a diameter of 1.5 cm and a height of 8 cm, and gradually immerse the plastic tube in liquid nitrogen at a speed of 6 mm / min until the dispersion is completely frozen into ice;

[0057] Step 3: put the above-mentioned frozen ice and the mold together into a freeze dryer and freeze-dry for 48 hours until the ice is completely sublimated to obtain a carbon nanotube three-dimensional network macroscopic body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com