Heterostructure self-supporting electrode material and preparation method and application thereof

A self-supporting electrode and heterostructure technology, applied in electrodes, battery electrodes, structural parts, etc., can solve the problems of poor conductivity of MOFs, lack of active sites, restricting the transfer process, etc., to achieve a simple preparation process, enhanced conductivity, The effect of large catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

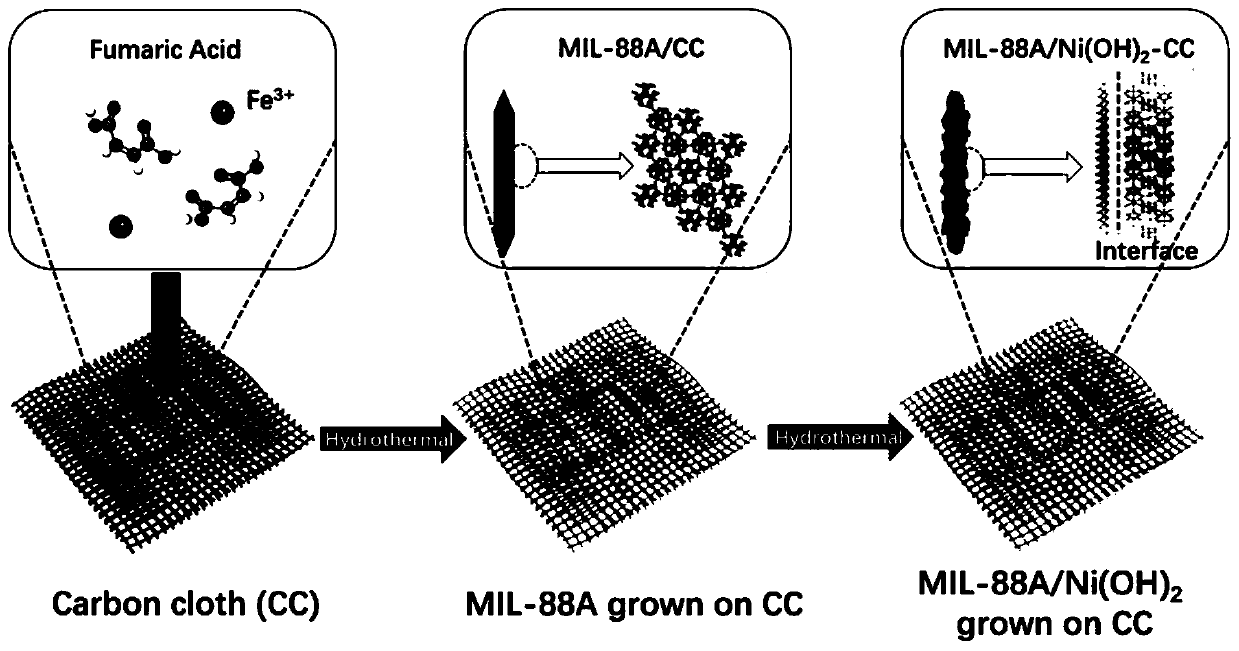

[0049] (1) will 5cm 2 Soak the carbon cloth in 50mL of acetone solution, sonicate for 1h, take out the carbon cloth, then soak it in 50mL of absolute ethanol for 20min, take out the carbon cloth and dry it in vacuum. Finally, place the above-mentioned carbon cloth in 50 mL of concentrated nitric acid (volume concentration: 86%) and soak it for 24 hours, take out the acid-etched carbon cloth and wash it with a large amount of deionized water until the solution is neutral, and place it in a vacuum oven at 40°C to dry for 12 hours. Cloth pre-processing process is completed, recorded as CC;

[0050] (2) 139.2mg fumaric acid (C 4 h 4 o 4 ) and CC into a 50mL beaker, add 25mL deionized water to ultrasonic for 15min, stir for 15min, until the solution is clear, slowly add 525.2mg ferric nitrate nonahydrate (Fe(NO 3 )3·9H 2 O) stirring for 5min, then transferred to a 50mL hydrothermal reaction kettle, heated at 110°C for 6h, and finally vacuum-dried to obtain MIL-88A / CC;

[0051...

Embodiment 2

[0059] (1) will 5cm 2 Soak the carbon cloth in 50mL of acetone solution, sonicate for 1h, take out the carbon cloth, then soak it in 50mL of absolute ethanol for 20min, take out the carbon cloth and dry it in vacuum. Finally, arrange the above-mentioned carbon in 50ml of concentrated nitric acid (volume concentration: 50%) and soak for 24h, take out the acid-etched carbon cloth and wash it with a large amount of deionized water until the solution is neutral, and place it in a vacuum oven at 40°C to dry for 12h. Cloth pre-processing process is completed, recorded as CC;

[0060] (2) 139.2mg fumaric acid (C 4 h 4 o 4 ) and CC into a 50mL beaker, add 25mL deionized water to ultrasonic for 15min, stir for 15min, until the solution is clear, slowly add 525.2mg ferric nitrate nonahydrate (Fe(NO 3 )3·9H 2 O) stirring for 5min, then transferred to a 50mL hydrothermal reaction kettle, heated at 110°C for 6h, and finally vacuum-dried to obtain MIL-88A / CC;

[0061] (3) Place the MI...

Embodiment 3

[0063] (1) will 5cm 2 Soak the carbon cloth in 50mL of acetone solution, sonicate for 1h, take out the carbon cloth, then soak it in 50mL of absolute ethanol for 20min, take out the carbon cloth and dry it in vacuum. Finally, arrange the above-mentioned carbon in 50ml of concentrated nitric acid (volume concentration: 86%) and soak for 24h, take out the acid-etched carbon cloth and wash it with a large amount of deionized water until the solution is neutral, and place it in a vacuum oven at 40°C for 12h to dry. Cloth pre-processing process is completed, recorded as CC;

[0064] (2) 139.2mg fumaric acid (C 4 h 4 o 4 ) and CC into a 50mL beaker, add 25mL deionized water to ultrasonic for 15min, stir for 15min, until the solution is clear, slowly add 525.2mg ferric nitrate nonahydrate (Fe(NO 3 )3·9H 2 O) stirring for 5min, then transferred to a 50mL hydrothermal reaction kettle, heated at 90°C for 6h, and finally vacuum-dried to obtain MIL-88A / CC;

[0065] (3) Place the MIL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com