High-performance polypyrrole-based ternary composite thermoelectric material and preparation method thereof

A polypyrrolyl-based ternary and thermoelectric material technology, which is applied in the preparation of high-performance polypyrrolyl-based ternary composite thermoelectric materials, composite electrothermal materials, and high-performance polypyrrolyl-based ternary composite thermoelectric materials, and can solve the problem of enhancing polypyrrolyl-based Ternary composite material system and other problems, to achieve the effect of good component dispersion uniformity, mild reaction and high thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Weigh 2 mL of aniline that has been distilled twice under reduced pressure, add it to 100 mL of concentrated hydrochloric acid with a concentration of 0.8 mol / L, stir evenly, and prepare aniline hydrochloric acid solution A; add 5 g of ammonium persulfate to 100 mL of 0.8 mol / L Prepare solution B in L of concentrated hydrochloric acid; mix solution A and solution B, place in a water bath at 30°C, and stir for 10 hours. The suspension was suction-filtered, washed with 0.8 mol / L hydrochloric acid solution, absolute ethanol, and deionized water until the filtrate was colorless; finally, the filter cake was dried in a vacuum oven at 60°C for 20 hours to obtain polyaniline powder.

[0048] 0.03mol FeCl 3 ·6H 2 O was dissolved in 30 mL distilled water for use. Add 3 g of graphene to 50 mL of ethanol solution (vol ethanol: vol water = 1:1), stir for 1 h, and ultrasonically treat for 2 h to obtain a uniformly dispersed graphene suspension, then dissolve 0.03 mol of pyrrole mo...

Embodiment 2

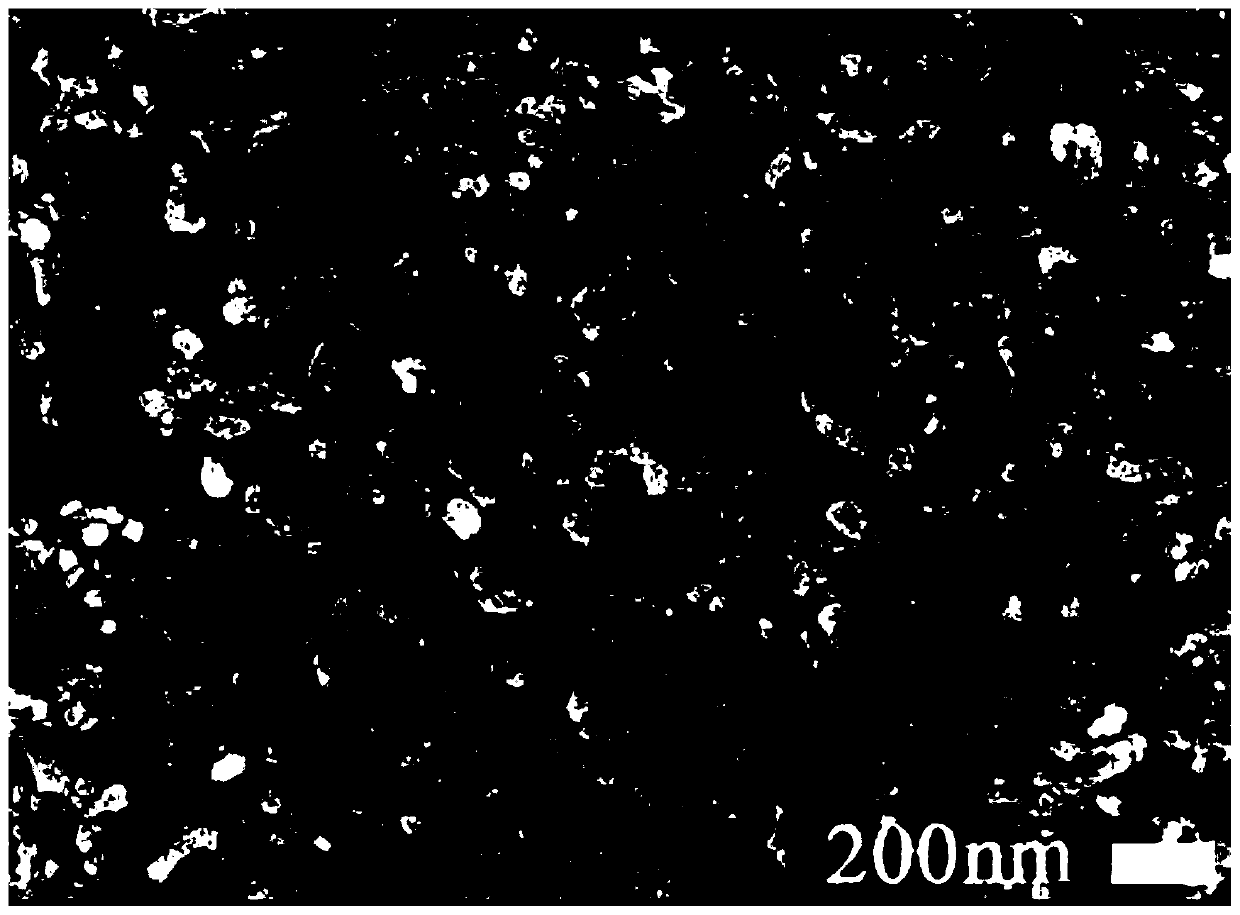

[0050] Weigh 2mL of aniline that has been distilled twice under reduced pressure, add it to 100mL of concentrated hydrochloric acid with a concentration of 1mol / L, stir well, and configure aniline hydrochloric acid solution A; add 2.5g of ammonium persulfate to 100mL of 1mol / L In concentrated hydrochloric acid, configure solution B; mix solution A and solution B, place in a water bath at 40°C, and stir for 8 hours. The suspension was suction-filtered, and washed with 1mol / L hydrochloric acid solution, absolute ethanol, and deionized water until the filtrate was colorless; finally, the filter cake was dried in a vacuum oven at 60°C for 20 hours to obtain polyaniline powder. figure 2 SEM image of the polyaniline nanorods prepared in this example.

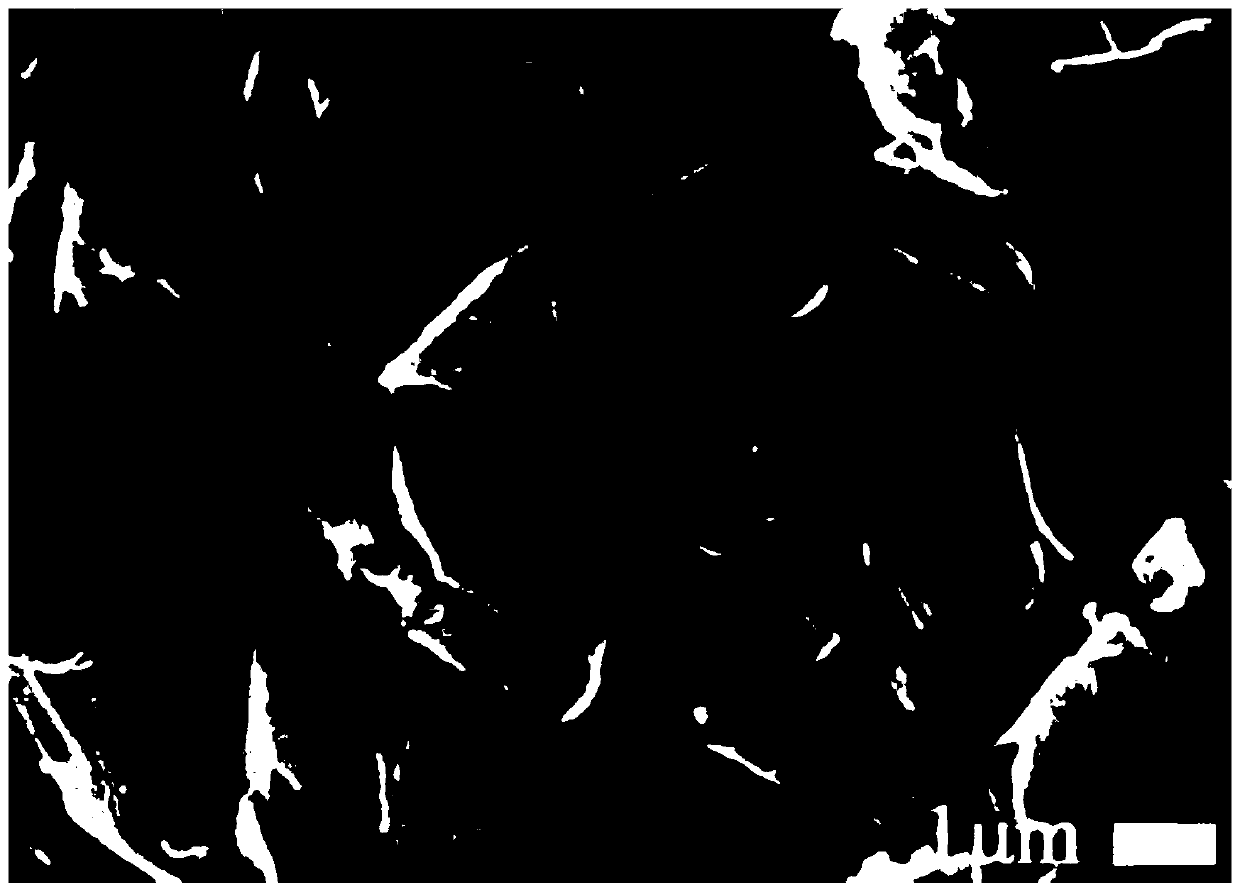

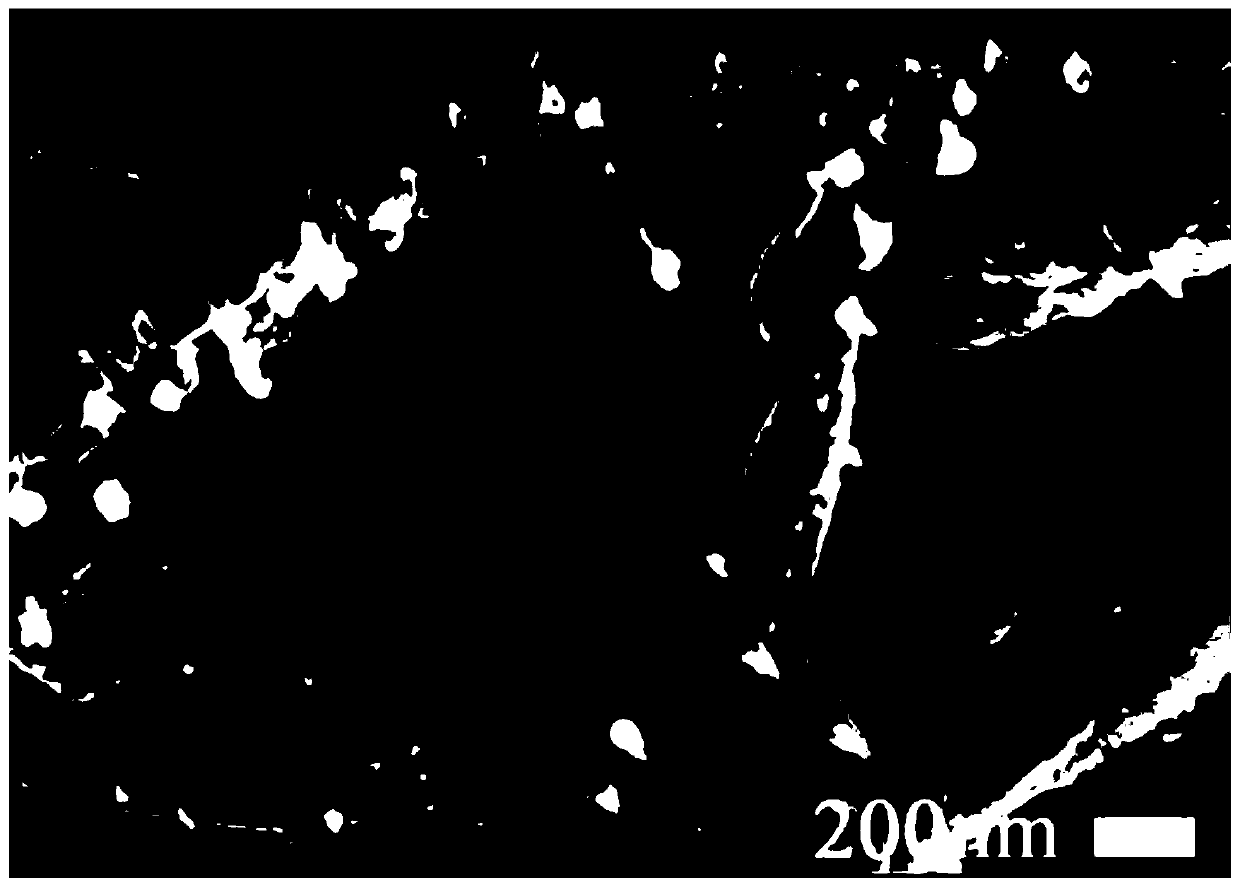

[0051] 0.04mol FeCl 3 ·6H 2 O was dissolved in 30 mL distilled water for use. 5g graphene ( figure 1 The SEM photo of the graphene nanosheets used in the examples) was added to 50mL ethanol solution (vol ethanol:vol water=1:1) an...

Embodiment 3

[0056] Weigh 1.5mL of aniline that has been distilled twice under reduced pressure, add it to 100mL of concentrated hydrochloric acid with a concentration of 1.5mol / L, stir well, and configure it as aniline hydrochloric acid solution A; add 3.4g of ammonium persulfate to 100mL of a concentration of 1.5 mol / L concentrated hydrochloric acid to prepare solution B; mix solution A and solution B, place in a water bath at 60°C, and stir for 12 hours. The suspension was suction-filtered, washed with 1.5 mol / L hydrochloric acid solution, absolute ethanol, and deionized water until the filtrate was colorless; finally, the filter cake was dried in a vacuum oven at 60°C for 20 hours to obtain polyaniline powder.

[0057] 0.06mol FeCl 3 ·6H 2 O was dissolved in 30 mL distilled water for use. Add 3 g of graphene to 50 mL of ethanol solution (vol ethanol: vol water = 1:1) and stir for 1 h, ultrasonicate for 2 h to obtain a uniformly dispersed graphene suspension, then dissolve 0.12 mol of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com