Multilayer silicon/graphene composite lithium battery positive electrode material and preparation method thereof

A graphene composite and negative electrode material technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of electrode cycle performance degradation, loss, corrosion, etc., achieve good cycle charge and discharge performance, improve cycle stability, Suppresses the effect of large volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

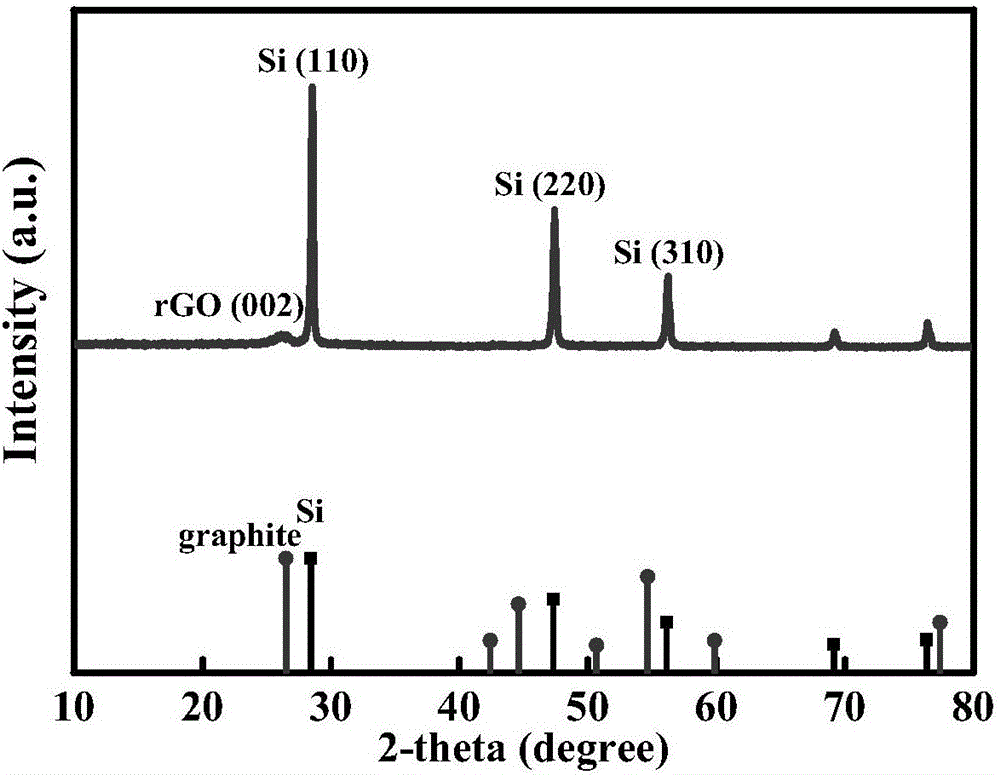

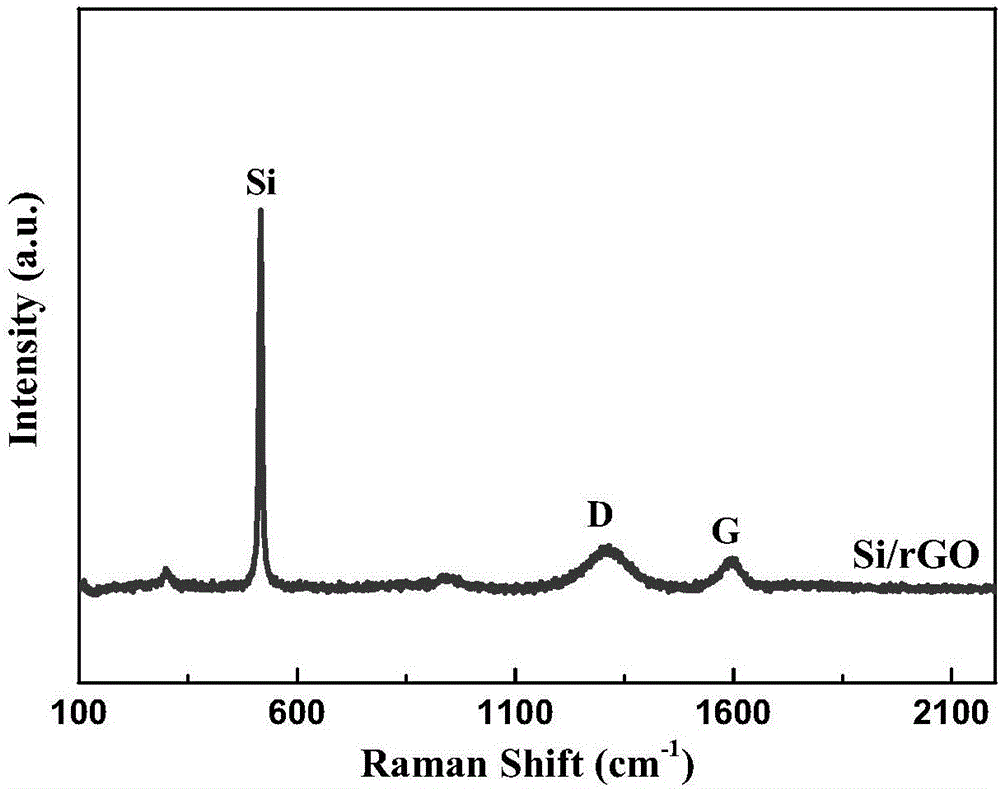

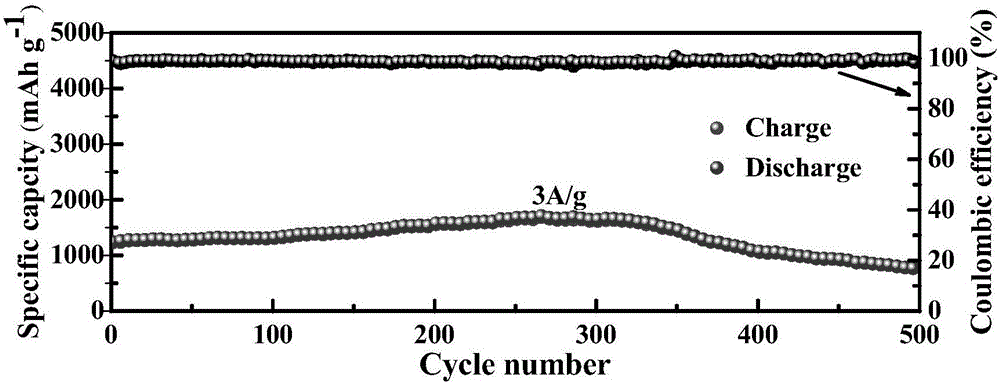

[0029] The present embodiment provides and prepares a kind of 5-layer nickel foam collector silicon / graphene composite lithium battery negative electrode material, comprises the following steps:

[0030] Step 1. Foamed nickel pretreatment: prepare 4M hydrochloric acid solution, add the foamed nickel pressed into discs into the hydrochloric acid solution, ultrasonically clean for 20 minutes, and then clean with absolute ethanol;

[0031] Step 2, adding the graphene oxide powder into absolute ethanol, ultrasonically dispersing for 60 minutes, and preparing a 1M graphene oxide solution;

[0032] Step 3. Drop HF into a mixed solution with a volume ratio of absolute ethanol: deionized water = 1:1 to prepare a 5M HF solution; then add nano-silicon to the HF solution, ultrasonically clean it for 20 minutes, and then centrifuge or suction filter; Add the cleaned nano-silicon to the mixed solution with a volume ratio of absolute ethanol: ethylene glycol = 9:1, and prepare a silicon dis...

Embodiment 2

[0045] Using the same process as in Example 1, 3-layer, 7-layer, 9-layer, and 11-layer silicon / graphene composite lithium battery negative electrode materials were prepared. The structure and electrical properties were characterized and the test results remained the same as in Example 1.

[0046] In short, through the design of the material structure, the layered graphene wraps the silicon nanopowder in it, so that the volume change of the silicon during the charge and discharge process will not affect the cycle effect, thereby forming a stable SEI film; its preparation method is a simple, practical , and an effective high-performance silicon composite negative electrode preparation method can realize the commercial lithium-ion battery application of silicon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com