Carbide doped porous carbon and preparation method thereof

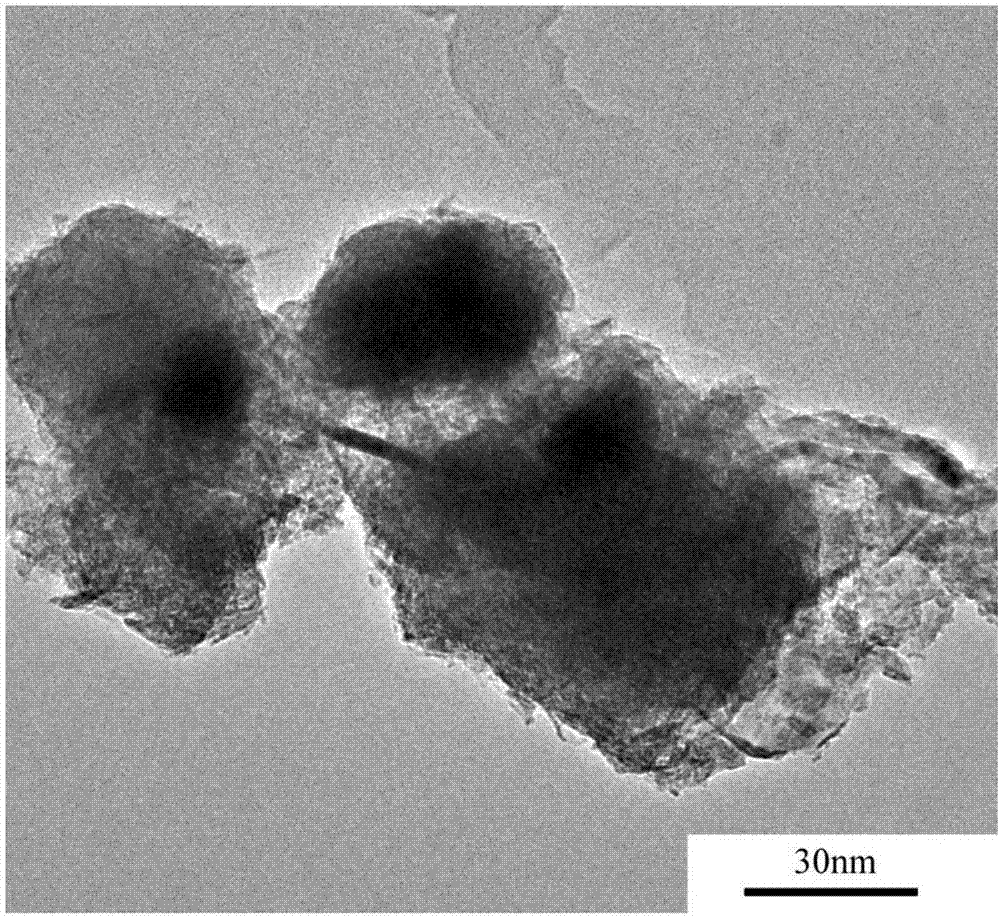

A porous carbon and carbide technology, applied in the field of porous carbon materials, can solve the problems of removal, pore shrinkage, and specific surface area reduction, and achieve the effects of improving conductivity, reducing bonding ability, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] For the carbide-doped porous carbon in which metal carbides are embedded in the porous carbon, the present invention provides a method for preparing the carbide-doped porous carbon described in the above technical solution, comprising the following steps:

[0058] (1) adding water to a mixed solution including an organic carbon source, an organic metal salt, a curing agent and an organic solvent for hydrolysis to obtain a hydrolyzed compound;

[0059] (2) surface oxidation is performed after the hydrolyzed complex obtained in the step (1) is solidified to obtain a composite oxidation product;

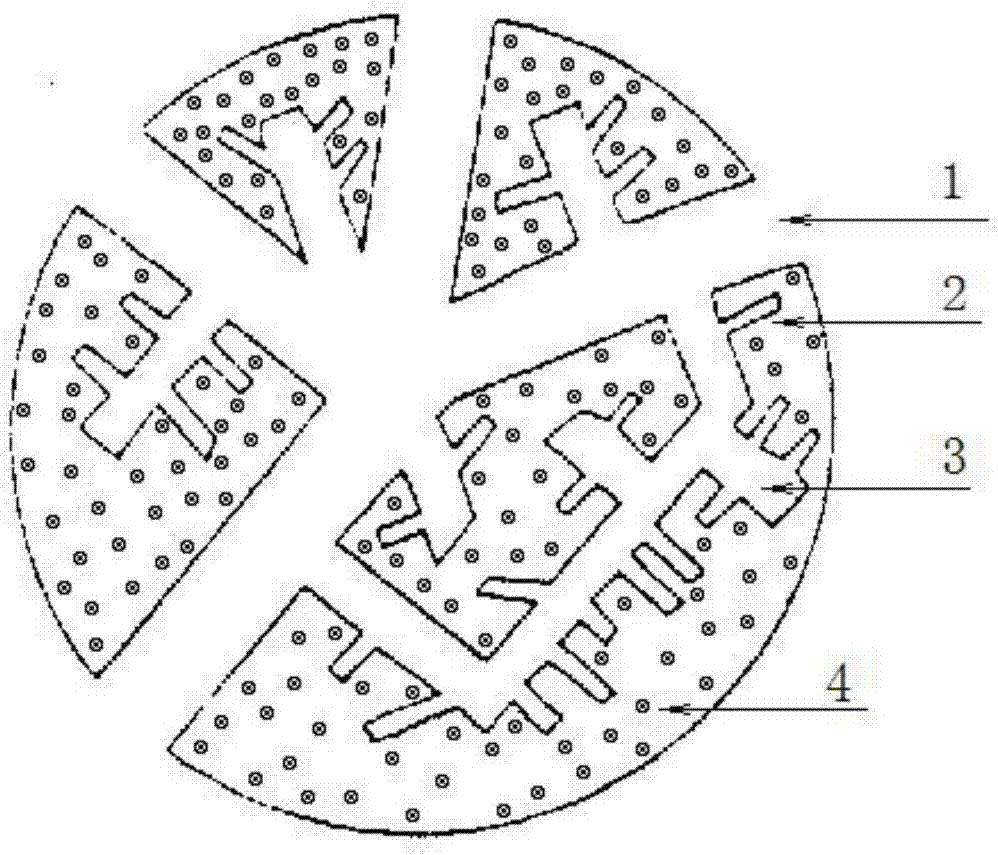

[0060] (3) subjecting the composite oxidation product obtained in step (2) to pressure treatment to obtain a preform;

[0061] (4) Carbonizing the preform obtained in step (3) to obtain carbide-doped porous carbon.

[0062] In the invention, water is added to a mixed solution including organic carbon source, organic metal salt, curing agent and organic solvent, and hydrolyzed to...

Embodiment 1

[0128] ① Mix phenolic resin, titanium ethoxide, hexamethylenetetramine and ethanol at a weight ratio of 100:3:5:100 at 25°C and fully stir and dissolve to obtain a mixed solution;

[0129] ②Keep at 25°C, add water dropwise to the mixed solution at a rate of 1.7mL / min and continue to stir for 0.5h until the titanium ethoxide is completely hydrolyzed to obtain a hydrolyzed complex. 50%;

[0130] ③ The hydrolyzed compound was heated and vacuum-evaporated at 80°C under continuous stirring to obtain a solidified material for 12 hours;

[0131] ④ After pulverizing the solidified material, heat and oxidize it in a fluidized bed at 180°C for 0.5h to obtain the oxidized material, wherein the particle size of the pulverized solidified material is controlled at D50 of 80 μm;

[0132] ⑤ Press the oxide material into a sheet with a thickness of 0.5mm and a diameter of 10mm under a pressure of 50MPa;

[0133] ⑥Put the preform into the carbonization reaction chamber, raise the temperature ...

Embodiment 2

[0144] ① Mix phenolic resin, titanium ethoxide, hexamethylenetetramine and ethanol at a weight ratio of 100:40:20:1000 at 0°C and fully stir to dissolve to obtain a mixed solution;

[0145] ②Heat the above solution to 70°C, then add water dropwise to the mixed solution at a rate of 1.7mL / min and continue to stir for 5h until the titanium ethoxide is completely hydrolyzed to obtain a hydrolyzed complex. Add about 500mL of water as a solvent 50% of the mass of ethanol;

[0146] ③ The hydrolyzed compound was heated at 100°C under vacuum evaporation and solidified under continuous stirring to obtain a solidified material for 12 hours;

[0147] ④ After pulverizing the solidified material, heat and oxidize it in a fluidized bed at 260°C for 0.5h to obtain a composite oxidation product, wherein the particle size of the pulverized solidified material is controlled at D50 of 80 μm;

[0148] ⑤ Compress the composite oxidation product into a sheet with a thickness of 0.2 mm and a diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com