Method for preparing silicon-carbon cathode material of lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied to battery electrodes, circuits, electrical components, etc., can solve problems such as volume effect and capacity fading that cannot be fundamentally suppressed, and achieve excellent cycle performance, easy operation, and weakened volume effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

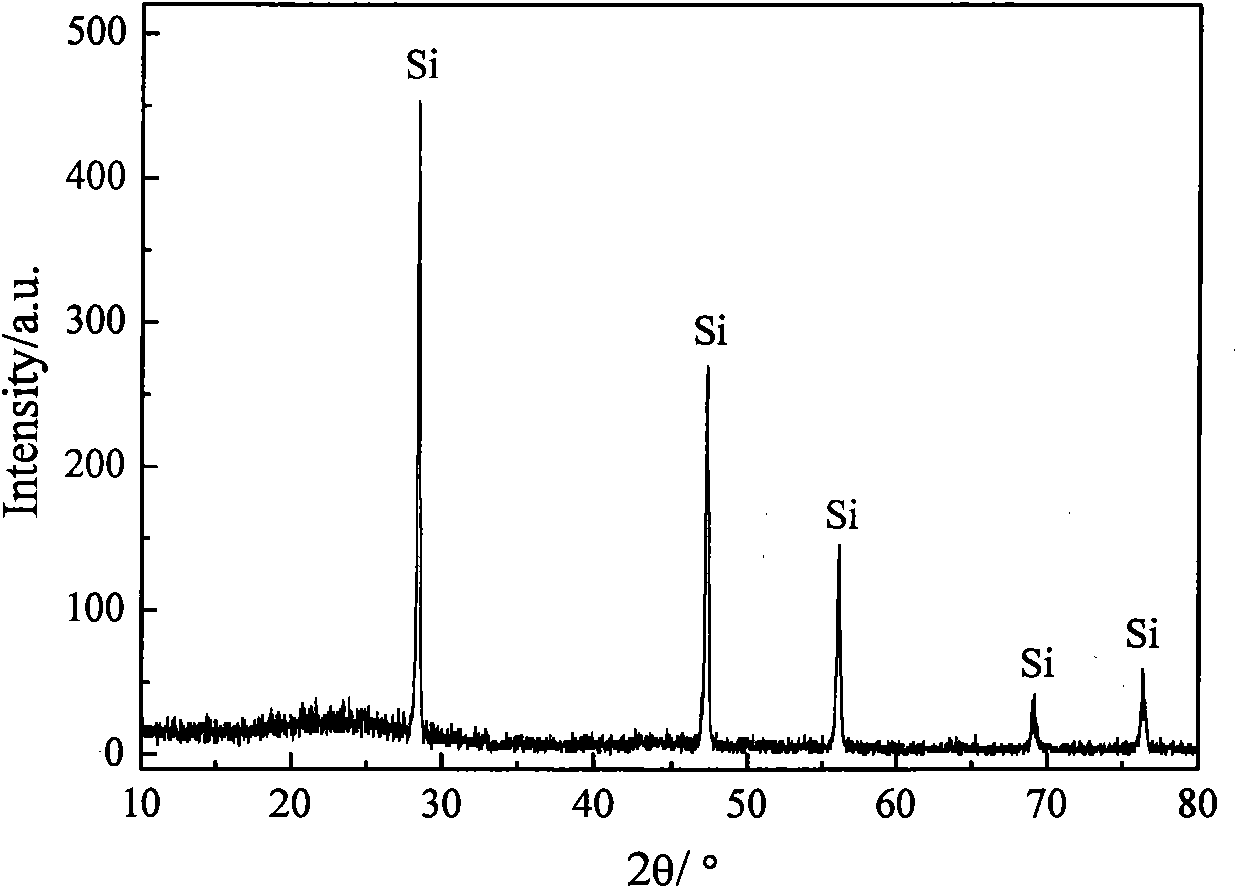

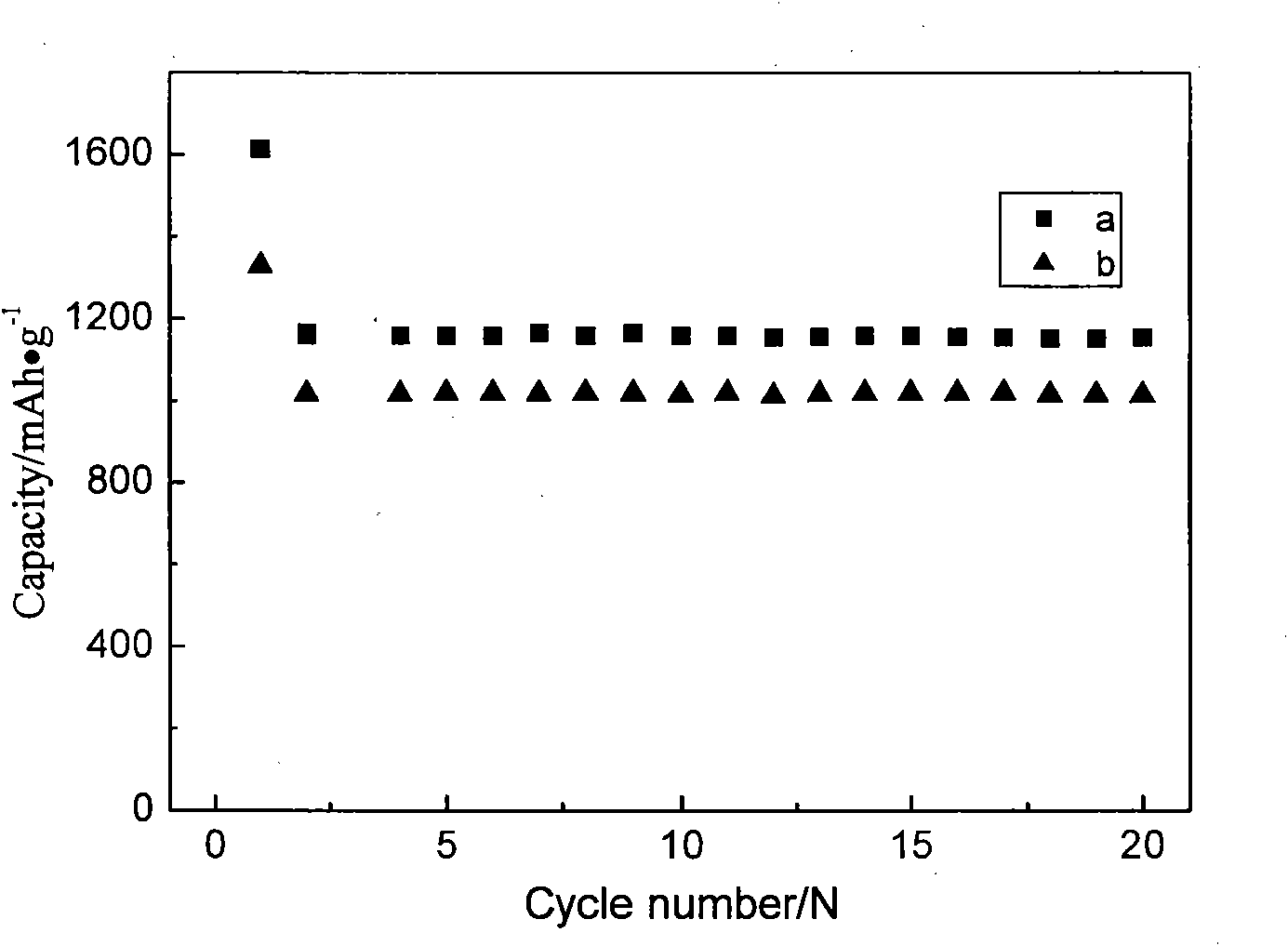

Embodiment 1

[0022] The preparation method of the lithium ion battery silicon carbon negative electrode material of the present embodiment comprises the following steps:

[0023] A: Add 2.20g of catechol, 2ml of formaldehyde and 5ml of concentrated hydrochloric acid into 10ml of ethanol, stir to dissolve completely, and form a phenolic monomer solution;

[0024] B: in the phenolic monomer solution in the A step, add the nano-silicon powder of 0.9g to form a mixed solution;

[0025] C: Put the mixed solution in step B into the reaction kettle, and place the reaction kettle in an ultrasonic cleaner for reaction, set the ultrasonic temperature to 60°C, and the ultrasonic power to 99%. After about 3 hours, the mixed solution is formed After gelling, seal the reactor and put it into the oven. The temperature of the oven is set at 80°C, and the reactor is placed in the oven for 24 hours to generate a blocky precursor;

[0026] D: Crush the precursor produced in step C, and dry it in an oven at ...

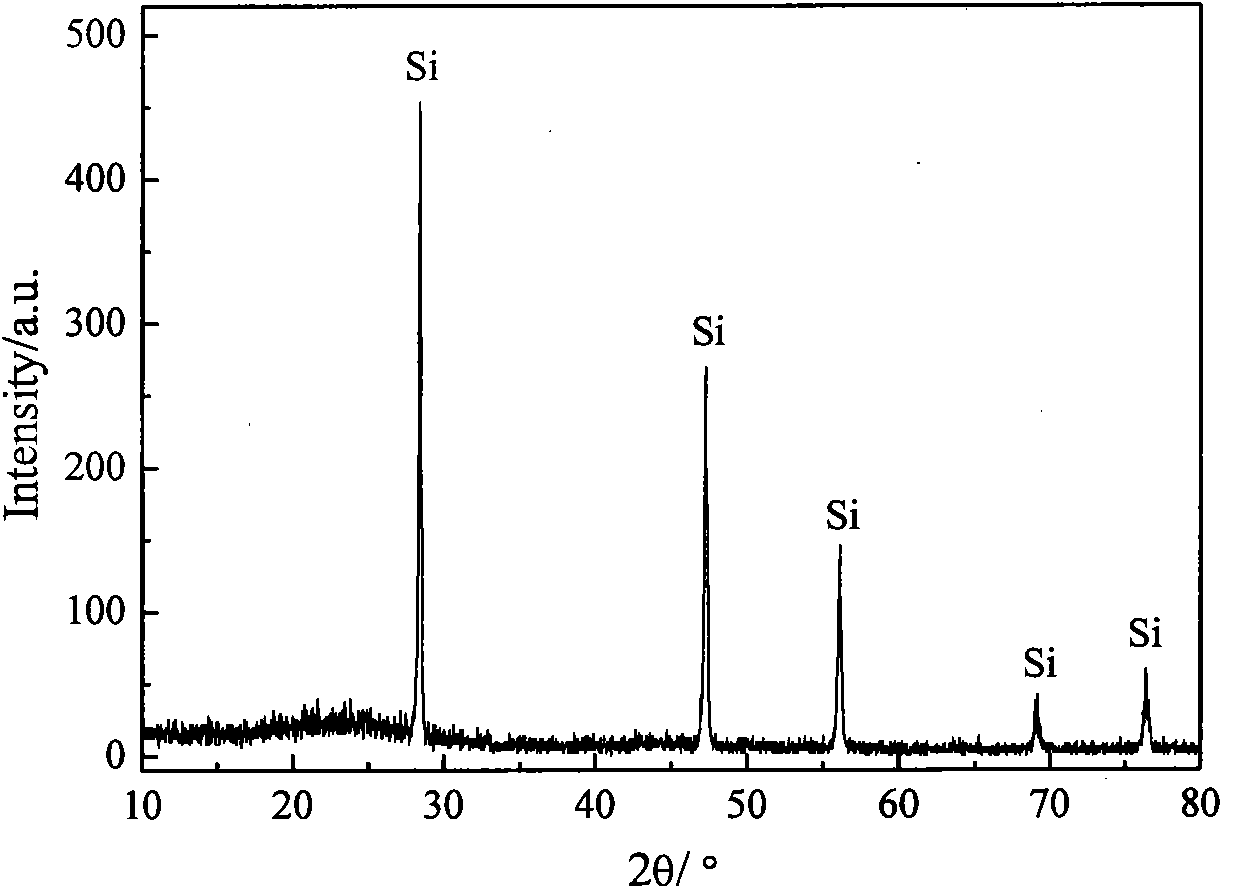

Embodiment 2

[0031] The preparation method of the lithium ion battery silicon carbon negative electrode material of the present embodiment comprises the following steps:

[0032] A: Add 1.88g of phenol, 2ml of formaldehyde and 5ml of concentrated hydrochloric acid into 10ml of ethanol, stir to dissolve completely, and form a phenolic monomer solution;

[0033] B: in the phenolic monomer solution in the A step, add the nano-silicon powder of 0.7g to form a mixed solution;

[0034] C: Put the mixed solution in step B into the reaction kettle, and place the reaction kettle in an ultrasonic cleaner for reaction, set the ultrasonic temperature to 75°C, and the ultrasonic power to 99%. After about 1.5 hours, the mixed solution is formed After gelling, seal the reactor and put it into the oven. The temperature of the oven is set to 120°C, and the reactor is placed in the oven for 12 hours to generate a blocky precursor;

[0035] D: Crush the precursor produced in step C, and dry it in an oven at...

Embodiment 3

[0039] The preparation method of the lithium ion battery silicon carbon negative electrode material of the present embodiment comprises the following steps:

[0040] A: Add 2.20g of hydroquinone, 2ml of benzaldehyde and 5ml of concentrated hydrochloric acid into 10ml of ethanol, stir to dissolve completely, and form a phenolic monomer solution;

[0041] B: in the phenolic monomer solution in the A step, add the nano-silicon powder of 1.3g to form a mixed solution;

[0042]C: Put the mixed solution in step B into the reaction kettle, and place the reaction kettle in an ultrasonic cleaner for reaction, set the ultrasonic temperature to 70°C, and the ultrasonic power to 99%. After about 2 hours, the mixed solution is formed After gelling, seal the reactor and put it into the oven. The temperature of the oven is set to 100°C, and the reactor is placed in the oven for 18 hours to generate a blocky precursor;

[0043] D: Grind the precursor produced in step C, and dry it in an oven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com