Silicon-carbon composite material and preparation method thereof, and lithium ion battery

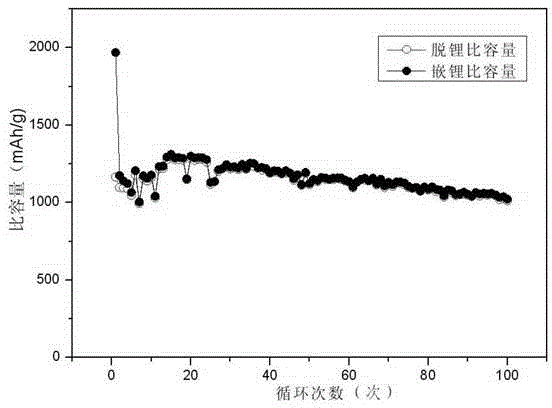

A silicon-carbon composite material and composite powder technology, applied in the field of lithium-ion batteries, can solve problems such as capacity decay, and achieve the effects of reduced volume effect, small size, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing a silicon-carbon composite material, including:

[0033] (1) Silica, conductive carbon material and metal compound

[0034] Add fumed silica (particle size: 30nm) to be ball-milled, graphite (150 mesh) as a conductive carbon material, and metal calcium particles (particle size: 1mm) into the ball mill tank of the planetary ball mill, in which fumed silica and The mass ratio of graphite is 1 / 9, and the quality of calcium metal particles is 70% of the theoretical calcium particle quality required for reducing fumed silica to silicon; reaction with metal), wherein the mass of toluene is 70% of the mass of the material to be milled; the ball milling beads are steel balls with a diameter of 20mm and 60mm, and the mass ratio of the milling beads to the material to be milled is 6; the speed of the ball milling is 400 rpm , ball milled for 4 hours to obtain a composite powder.

[0035] (2) Reduction reaction

[0036] Take the d...

Embodiment 2

[0045] This embodiment provides a method for preparing a silicon-carbon composite material, including:

[0046] (1) Silica, conductive carbon material and metal compound

[0047] Add the porous silica gel to be ball-milled, acetylene black as conductive carbon material, and metal sodium particles (particle size 1mm) into the ball mill tank of the planetary ball mill, wherein the mass ratio of porous silica gel to acetylene black is 0.5, and the mass ratio of metal sodium particles The quality is 50% of the theoretical sodium metal particles required for reducing the porous silica gel to silicon; then add ether as an alkane dispersant in the ball mill jar, wherein the quality of ether is 50% of the mass of the material to be ball milled; the ball milling beads have a diameter of 20mm and 60mm steel balls, wherein the mass ratio of the milling balls to the material to be milled is 6; the rotational speed of the ball milling is 300 rpm, and the ball milling is 2 hours to obtain a c...

Embodiment 3

[0056] This embodiment provides a method for preparing a silicon-carbon composite material, including:

[0057] (1) Silica, conductive carbon material and metal compound

[0058] Add the mesoporous silica to be ball-milled, the vapor-grown carbon fiber and metal potassium particles (particle size 1mm) as the conductive carbon material into the ball milling tank of the planetary ball mill, wherein the mass of the mesoporous silica and the vapor-grown carbon fiber Ratio is 9, and the quality of metal potassium particle is 100% of the theoretical metal potassium particle quality required for reducing mesoporous silica to silicon; The mass is 150% of the mass of the material to be milled; the ball milling beads are steel balls with a diameter of 20mm and 60mm, wherein the mass ratio of the milling beads to the material to be milled is 6; the speed of the ball mill is 500 rpm, and the ball mill is 8h to obtain a composite powder .

[0059] (2) Reduction reaction

[0060] Take th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com