Silicon-based negative electrode material and preparation method thereof, negative electrode and lithium ion battery

A silicon-based negative electrode material and silicon-based technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor electrical conductivity of silicon oxide, difficulty in meeting application requirements, and low initial Coulombic efficiency, etc., to improve electrical conductivity , Improve the reversible capacity and alleviate the effect of volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In the prior art, the negative electrode materials of lithium ion batteries have problems such as poor electrical conductivity, large volume expansion effect, and poor cycle performance. Therefore the present invention provides a kind of preparation method of silicon-based negative electrode material of lithium ion battery, comprising,

[0045] Taking silicon oxide as a raw material,

[0046] Firstly, the silicon oxide raw material is subjected to surface modification treatment,

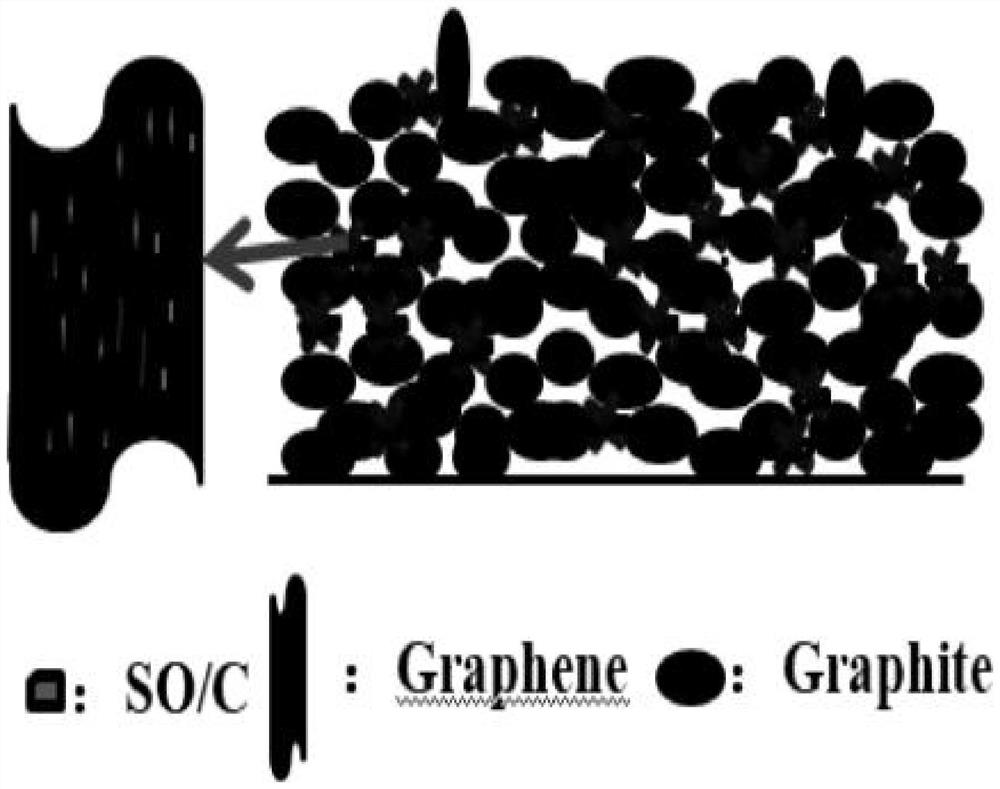

[0047] Then, the silicon-based capacity unit is prepared by combining the surface-modified silicon oxide with few-layer graphene,

[0048]Then the silicon-based capacity unit and the carbon-based material are mixed to prepare the silicon-based negative electrode material.

[0049] Correspondingly, the present invention also provides a silicon-based negative electrode material for a lithium-ion battery, which is prepared by the above-mentioned method.

[0050] Correspondingly, the present in...

Embodiment 1

[0053] This embodiment discloses a method for preparing a silicon-based negative electrode material for a lithium-ion battery, comprising: taking silicon oxide as a raw material, first performing surface modification treatment on the silicon oxide raw material; A few-layer graphene is combined to prepare a silicon-based capacity unit; then the silicon-based capacity unit is mixed with a carbon-based material to obtain a silicon-based negative electrode material product.

[0054] The method of this embodiment specifically includes the following steps:

[0055] S1, surface modification treatment: take the silicon oxide raw material, use carbon source A to pre-coat the silicon oxide raw material, and / or use the doping source to perform ion doping treatment on the silicon oxide raw material, to obtain Modified silica.

[0056] In this embodiment, silicon oxide raw materials with a particle size of 3-12 μm are preferably used. Pre-coating treatment refers to the deposition of a n...

Embodiment 2

[0079] This embodiment discloses a method for preparing a silicon-based negative electrode material for a lithium-ion battery, which includes first adopting a gas phase method, using acetylene as a gas carbon source (i.e. carbon source A1), and modifying the surface of silicon oxide to A dense nano-carbon layer is formed on the surface, and then the modified silicon oxide is used to prepare a silicon-based capacity unit and further prepare a silicon-based negative electrode material.

[0080] The specific steps of the preparation method of this embodiment are as follows:

[0081](1) Take 5kg of silicon oxide raw material, put it into CVD (chemical vapor deposition) equipment, heat it to 950°C, and keep it warm, wherein the heating rate is preferably 5°C / min, and the holding time is preferably 15min. Then feed acetylene and argon into the CVD equipment to decompose acetylene at 950°C and argon and deposit it on the surface of silicon oxide to form a nano-carbon layer (single ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com