Vapor chamber and manufacturing method thereof

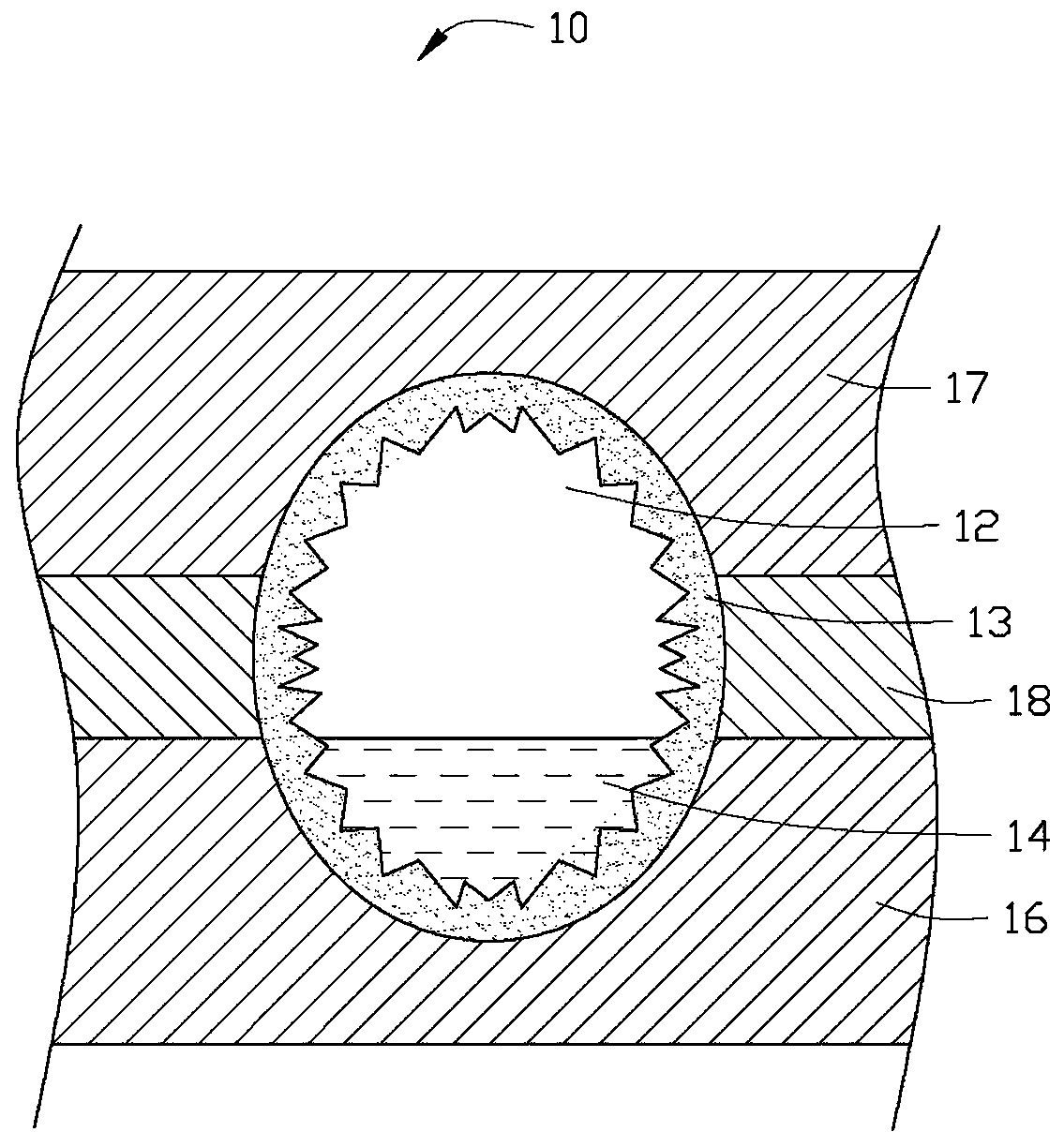

A technology of vapor chamber and manufacturing method, which is applied in cooling/ventilation/heating transformation, lighting and heating equipment, indirect heat exchangers, etc., and can solve problems such as affecting heat dissipation effect and reducing the volume of cavity 12

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] see Figure 2 to Figure 9 , the embodiment of the present invention provides a method for manufacturing a vapor chamber 20, comprising the following steps:

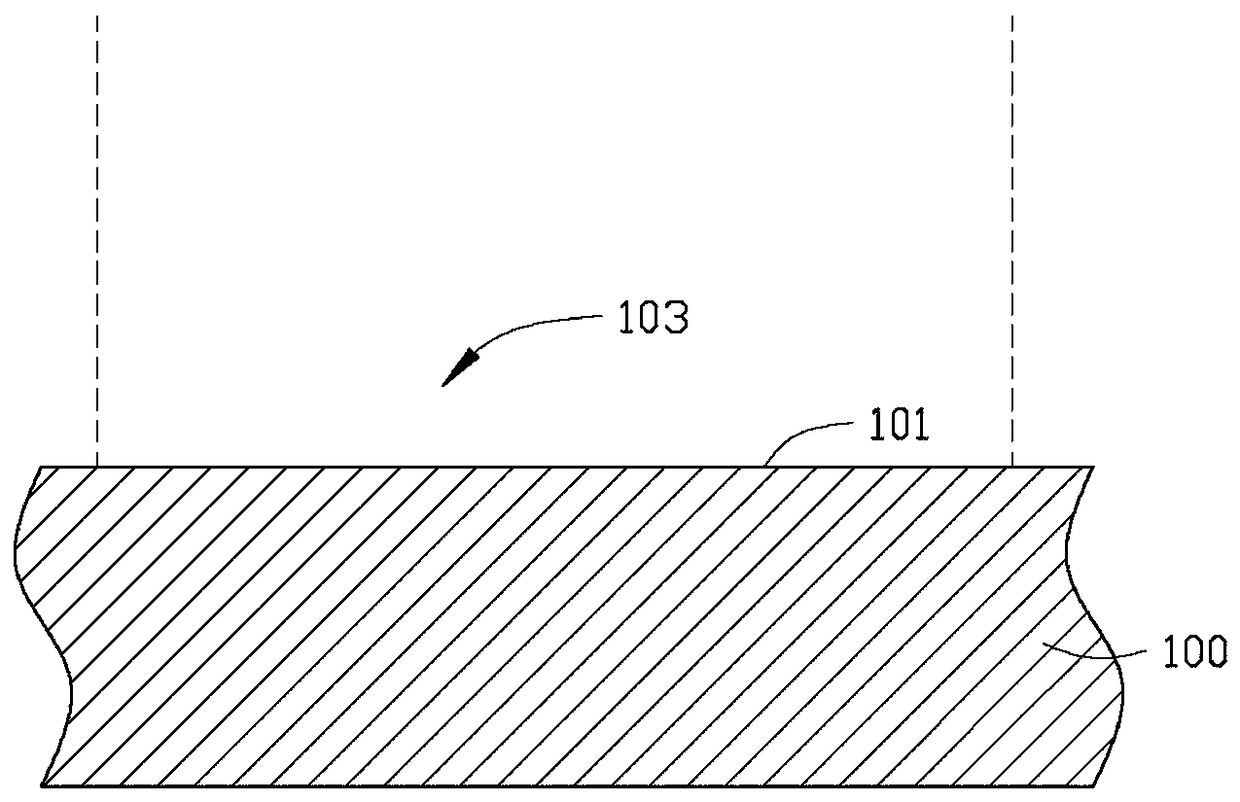

[0028] For a first step, see figure 2 , providing a first bottom plate 100 .

[0029] The material of the first bottom plate 100 is metal, such as magnesium-aluminum alloy, aluminum alloy, magnesium alloy, aluminum, copper, etc. In this embodiment, the first bottom plate 100 is a pure copper plate, and the first bottom plate 100 includes a flat The first surface 101 of the first surface 101 includes at least one cavity area 103 (only one is shown in the figure, in other embodiments, it can also be 3 or 5, when there is one more cavity area 103 , multiple cavity regions 103 are arranged side by side).

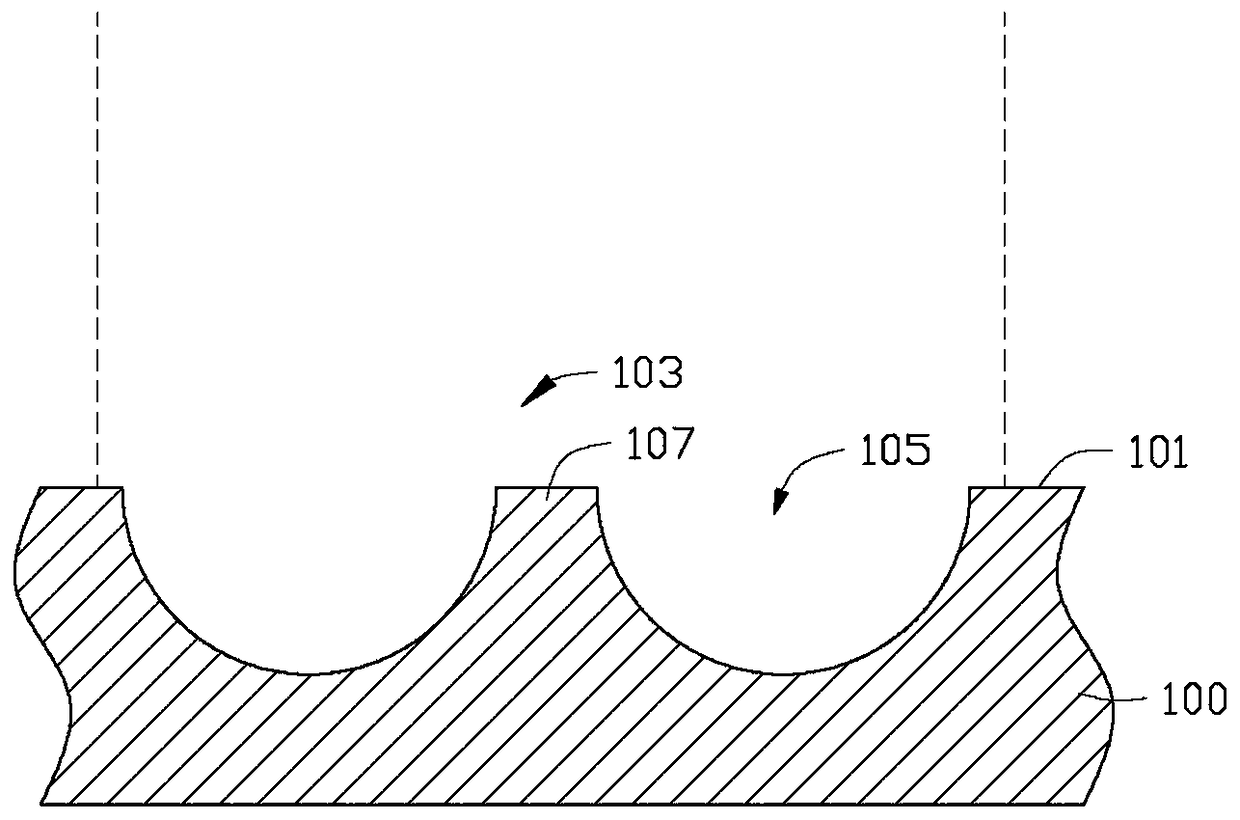

[0030] In the second step, please also refer to the image 3 and Figure 4 , etch the first surface 101 to obtain several first grooves 105 arranged side by side in each cavity area 103 (only two are shown in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com