Silicon-based composite material, preparation method thereof, negative electrode and lithium ion battery

A silicon-based composite material and powder technology, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve problems such as poor cycle performance, uncontrollable nano-silicon quantity, and increased production costs, so as to improve electrical conductivity and inhibit Effect of volume expansion and improvement of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

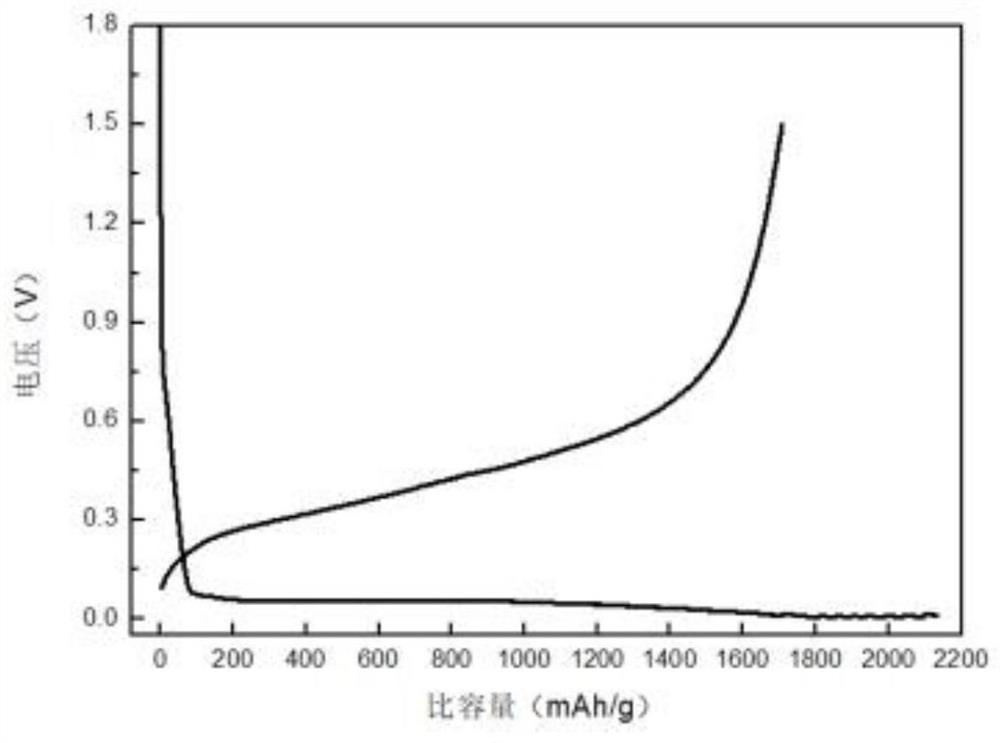

[0050] In the prior art, the negative electrode materials of lithium ion batteries have problems such as poor electrical conductivity, large volume expansion effect, and poor cycle performance. Therefore the present invention provides a kind of preparation method of silicon-based negative electrode material of lithium ion battery, comprising,

[0051] S1, performing the first carbon coating treatment on silicon and silicon oxide to obtain the first powder;

[0052] S2, subjecting the first powder to a second carbon coating treatment to obtain a second powder;

[0053] S3, sieving and demagnetizing the second powder to obtain a silicon-based composite material.

[0054] Correspondingly, the present invention also provides a silicon-based composite material prepared according to the above method.

[0055] Correspondingly, the present invention also provides a negative electrode of a lithium-ion battery, comprising the above-mentioned silicon-based composite material.

[0056]...

Embodiment 1

[0058] This embodiment discloses a method for preparing a silicon-based composite material, including:

[0059] S1, performing the first carbon coating treatment on silicon powder and silicon oxide powder to obtain a first powder.

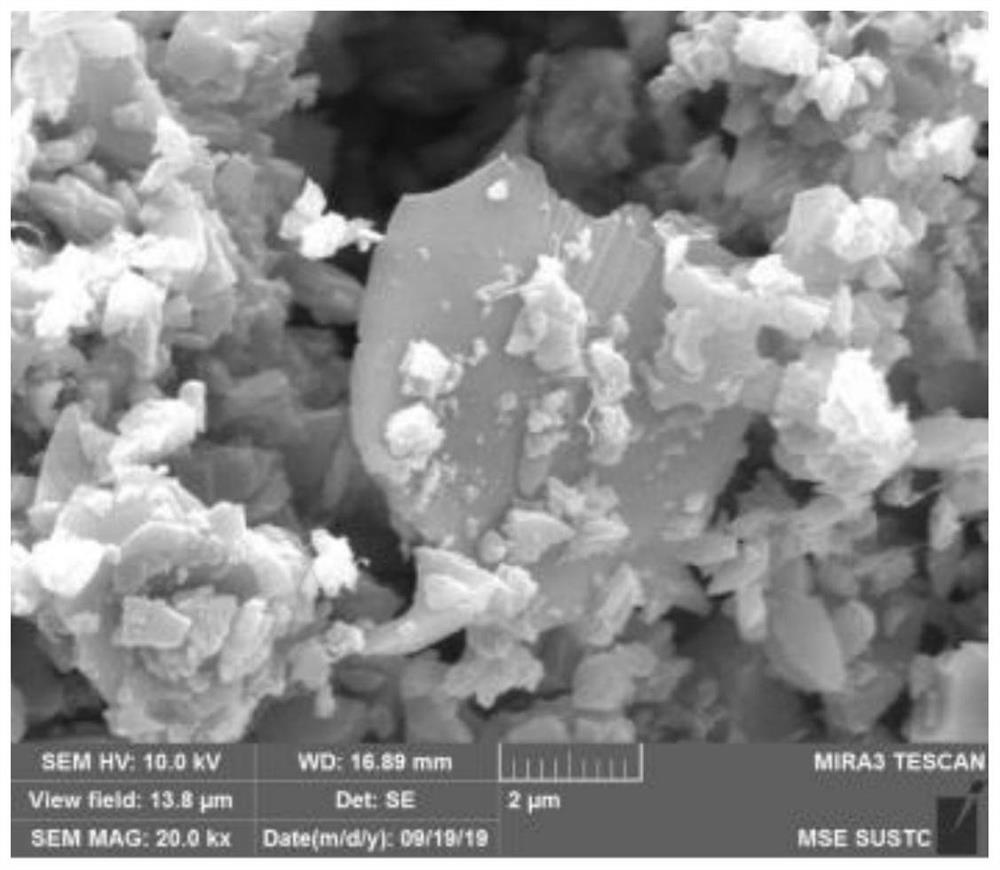

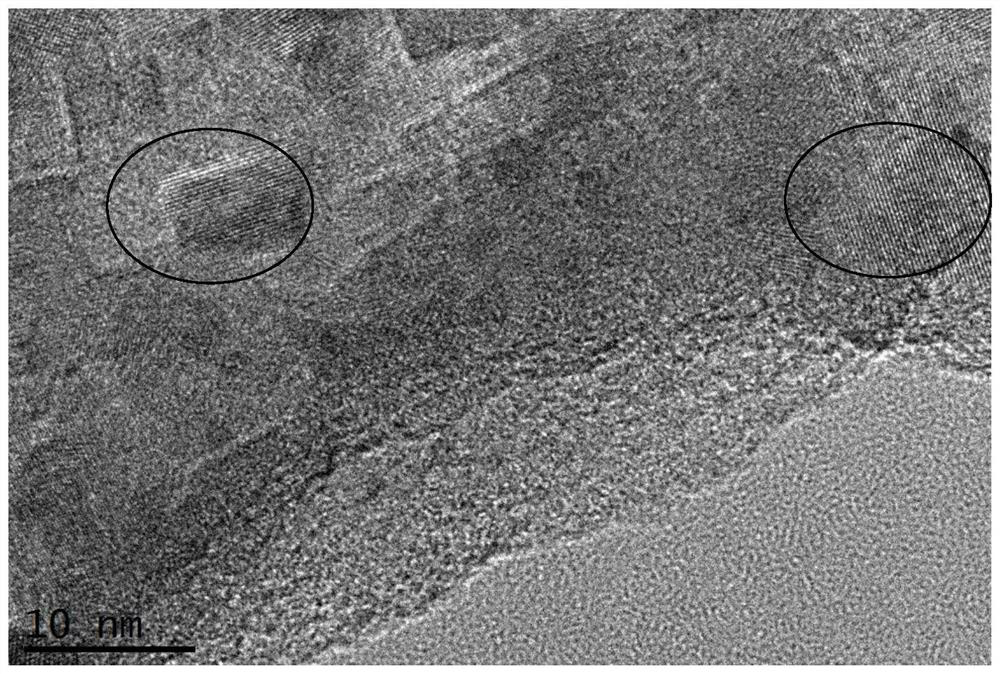

[0060] Specifically, first, silicon powder particles, silicon oxide powder particles, a first carbon source, and a first solvent are wet-grinded to obtain a first mixed liquid. Among them, the size of silicon powder particles is preferably 1-50 nm, and the size of silicon oxide powder particles is preferably 0.5-20 μm; the mass ratio of silicon powder to silicon oxide powder is preferably (1-20): 100; the powder of silicon oxide is preferably silicon oxide SiOx (wherein, x=0.8~1); the first carbon source can be citric acid, sucrose, glucose, maltose, pitch, phenolic resin, epoxy resin, polypyrrole, One or more polyanilines, the quality of the first carbon source is 5% to 15% of the powder mass of silicon oxide; the first solvent can be ethanol, isop...

Embodiment 2

[0073] This embodiment discloses a method for preparing a silicon-based composite material, including:

[0074] (1) Take 10g of silicon powder with D50 (also known as median diameter or median diameter, which refers to the corresponding particle diameter value when the cumulative distribution percentage reaches 50%) of 30nm, and 1000g of silicon oxide with D50 of 10μm, and place them in 3L In the absolute ethanol solution, add 46g of asphalt, and then place it in a sand mill with a speed of 3000rpm / min for grinding for 3 hours, wherein the grinding medium is imported high-purity grinding zirconium beads with a diameter of 1.0mm; after grinding, grind The final material was subjected to vacuum rotary evaporation treatment, and the obtained solid material was placed in a carbonization furnace filled with argon, and treated at 600° C. for 2 hours to obtain the first powder.

[0075] (2) Get above-mentioned first powder material, be placed in 3L dehydrated ethanol solution, simult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com