Carbon-coated ferroferric oxide/nitrogen-doped grapheme composite material and preparation method thereof

A carbon-coated ferric oxide and nitrogen-doped graphene technology is applied in the field of materials and electrochemistry, which can solve the problems of low electrical conductivity, large volume change, and limited application of ferric oxide materials, so as to improve the electrochemical performance. performance, high rate capability, and the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Graphene oxide was prepared by the traditional Hummers method. Assemble a 250ml reaction bottle in an ice-water bath, add 23ml of concentrated sulfuric acid, add 2g of natural flake graphite powder and 1g of sodium nitrate under stirring, control the temperature below 4°C for 2 hours during the whole process, and then gradually add 6g of potassium permanganate to control the reaction The temperature does not exceed 20°C, stir and react for 1h, then raise the temperature to about 35°C and continue to stir for 30min, then slowly add 60ml of deionized water, stir for 20min, and add 25ml of hydrogen peroxide (30Vol%) to react for 15min to turn the solution into bright yellow, and use 40ml HCl solution (10Vol%) was dissolved, centrifuged and washed with deionized water until the pH value was close to neutral, and finally the obtained graphene oxide aqueous solution was freeze-dried (vacuum, -50° C.) to obtain graphene oxide.

[0035] Step 1. Dissolve 300 mg of graphene oxide...

Embodiment 2

[0041] Step 1. Dissolve 300 mg of graphene oxide in 30 mL of distilled water, stir and sonicate for 20 minutes to obtain a uniform suspension;

[0042] Step 2. Add 1 g (5 mmol) of ferrous chloride tetrahydrate to the suspension obtained in step 1, and stir for 10 min;

[0043] Step 3: Add 1.0 g of melamine to the mixture obtained in Step 2, stir for 30 min, then add 2 ml of formaldehyde solution, transfer the mixed solution to a 100 ml polytetrafluoroethylene liner, and react in a hydrothermal kettle at 190° C. for 5 h.

[0044] Step 4, filter the reaction product obtained in step 3, transfer the filtered solid product to 200mL30wt% ammonia water, let it stand for 1h, and obtain the ferric oxide / melamine resin / graphene composite material, and freeze-dry the material deal with.

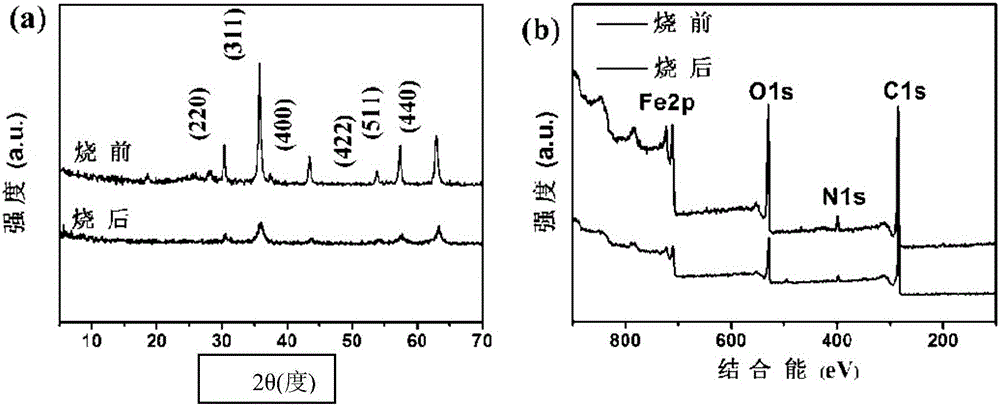

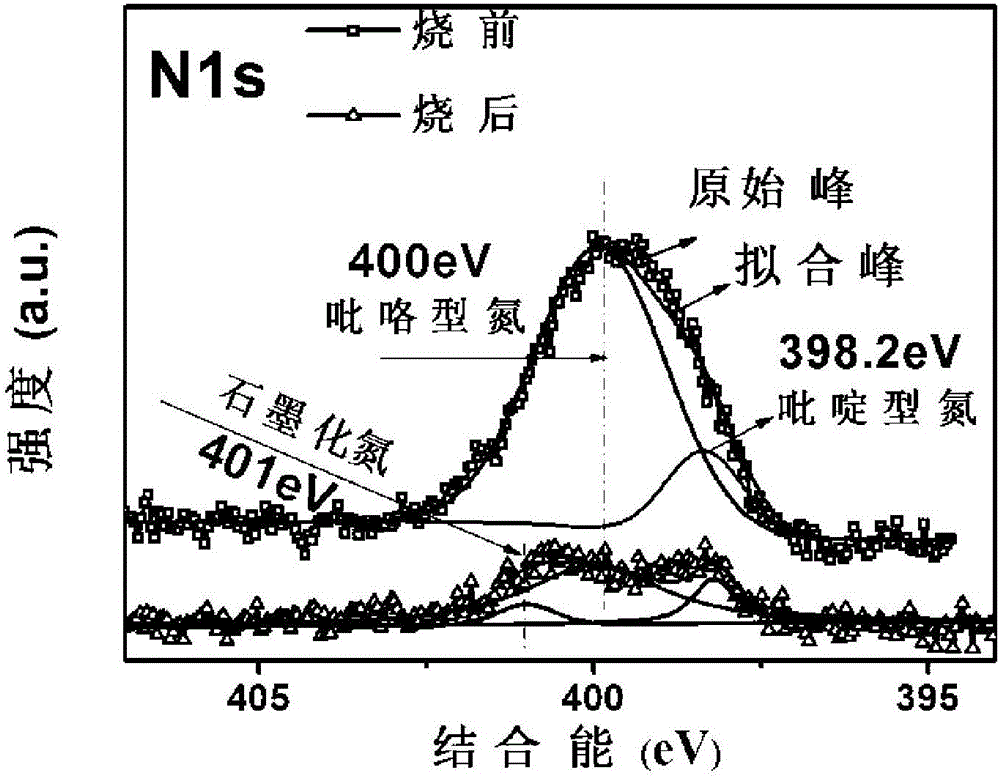

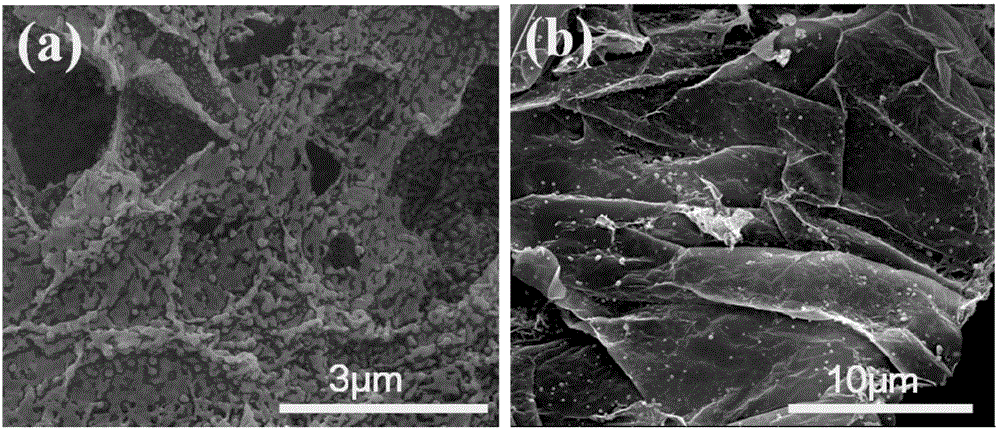

[0045] Step 5. Sinter the freeze-dried Fe3O4 / melamine resin / graphene composite material in a tube furnace at 700 °C under nitrogen protection for 3 hours to obtain carbon-coated Fe3O4 / nitrogen-doped g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com