Power lithium ion battery silicon-carbon composite negative electrode material preparation method

A lithium-ion battery, silicon-carbon composite technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of limited application, large specific surface area of materials, low initial efficiency, etc., to suppress agglomeration, suppress volume effect, avoid The effect of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

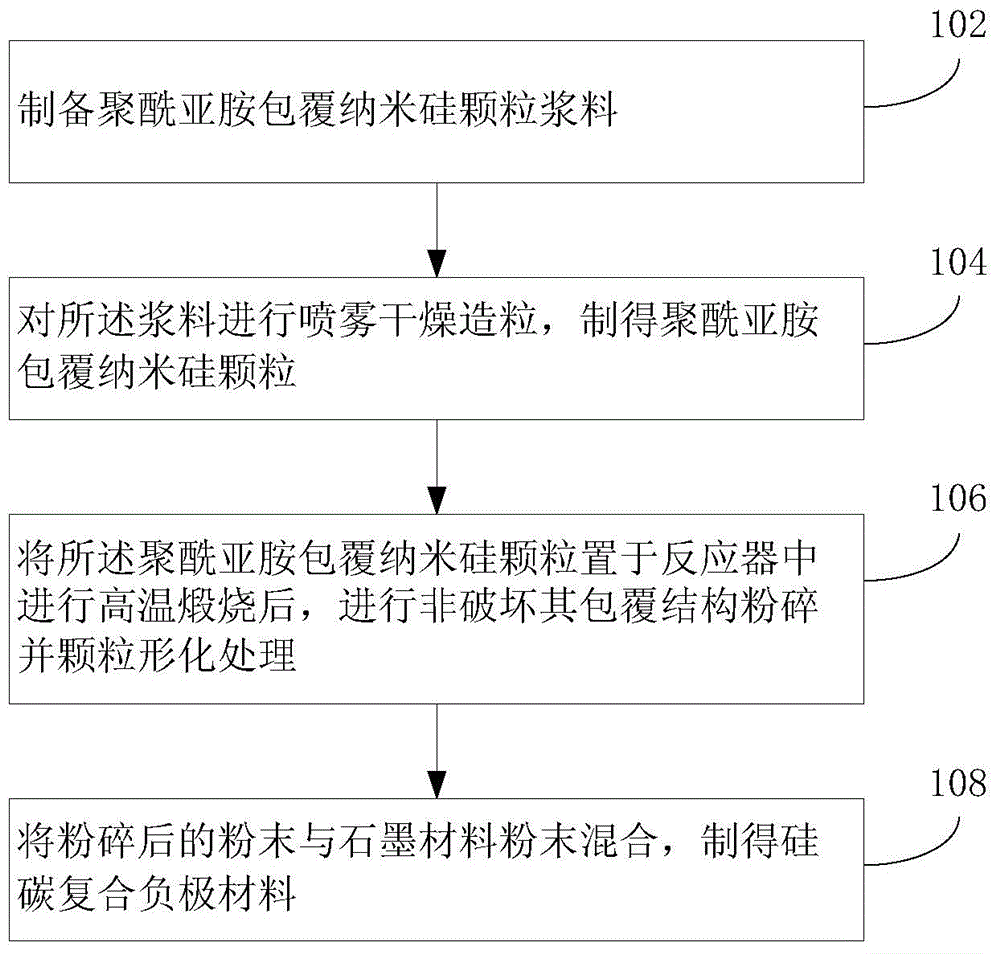

[0034] Such as figure 1 As shown, the preparation method of the power lithium-ion battery silicon-carbon composite negative electrode material of the present application, an embodiment thereof, comprises the following steps:

[0035] Step 102: Prepare polyimide-coated nano-silicon particle slurry.

[0036] Step 104: Spray-drying and granulating the slurry to obtain polyimide-coated nano-silicon particle powder.

[0037] When the slurry is spray-dried and granulated, the feed rate is 5Kg / h-15Kg / h, the air inlet temperature is 200-300°C, the air outlet temperature is 90-150°C, and the spray frequency is 250-350Hz. Spray drying can be performed in a spray dryer or spray drying equipment.

[0038] Step 106: After placing the polyimide-coated nano-silicon particle powder in a reactor for high-temperature calcination, carry out non-destroying coating structure crushing and granulation treatment.

[0039] The polyimide-coated nano-silicon particles are calcined in a reactor, at a ...

Embodiment 1

[0057] one. Preparation of polyimide-coated nano-silicon particle slurry: under the condition of ultrasonic power of 150w, add 1Kg of nano-silicon particle powder and 30g of silane coupling agent to 600g of N,N'-dimethylacetamide, and ultrasonically stir for 12h , then add 2Kg of 4,4'-diaminodiphenyl ether to the reaction system, stir until the 4,4'-diaminodiphenyl ether is completely dissolved, and put 2. Add 178Kg pyromellitic dianhydride to the reaction system in 4 times, stir for 12 hours to obtain a composite glue, then degrade the composite glue in a hot water bath at a temperature of 30°C for 30 minutes, and filter to remove gases and impurities , and finally carry out chemical imidation with 1kg acetic anhydride and 1kg pyridine to obtain nano-silicon particle / polyimide slurry;

[0058] two. Preparation of polyimide-coated nano-silicon particles: the slurry was spray-dried and granulated, the feed rate was 5Kg / h, the air inlet temperature was 200°C, the air outlet te...

Embodiment 2

[0064] one. Preparation of polyimide-coated nano-silicon particle slurry: under the condition of ultrasonic power of 180w, add 1Kg of nano-silicon particle powder and 40g of silane coupling agent to 700g of N,N'-dimethylacetamide, and ultrasonically stir for 14h , then add 3Kg of 4,4'-diaminodiphenyl ether to the reaction system, stir until the 4,4'-diaminodiphenyl ether is completely dissolved, and put 3. Add 267Kg of pyromellitic dianhydride to the reaction system in 4 times, stir for 14 hours to obtain a composite glue, then degrade the composite glue in a hot water bath at a temperature of 30°C for 30 minutes, and filter to remove gases and impurities , and finally carry out chemical imidation with 1.5Kg acetic anhydride and 1.5Kg pyridine to obtain nano-silicon particle / polyimide slurry;

[0065] two. Preparation of nano-silicon particles / polyimide particles: The slurry is spray-dried and granulated, the feed rate is 6Kg / h, the air inlet temperature is 220°C, the air ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com