Preparation method for composite negative electrode material of lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of volume effect and pulverization and shedding reducing battery efficiency and cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1. Preparation of nanoporous silicon / copper / graphite composite negative electrode material for lithium ion battery:

[0019] (1) Mix 1 g of silicon oxide powder and 0.6 g of aluminum powder in an argon atmosphere at room temperature at a mass ratio of 1:0.6, place them in a stainless steel ball mill jar equipped with an O-ring, put stainless steel balls, and keep The argon atmosphere in the tank, the rotating speed of the high-energy ball mill is 400 rpm, and the ball milling time is 15 hours, and about 1.4g of highly dispersed nano-silicon / alumina composites are obtained;

[0020] (2) Mix 0.5g of nano-silicon / alumina composite with 0.45g of metal copper powder in an argon atmosphere at room temperature at a mass ratio of 1:0.9, place them in a stainless steel ball mill jar equipped with an O-ring, and put Stainless steel balls to keep the argon atmosphere in the tank, the speed of the high-energy ball mill is 400 rpm, and the ball milling time is 2 hours to ...

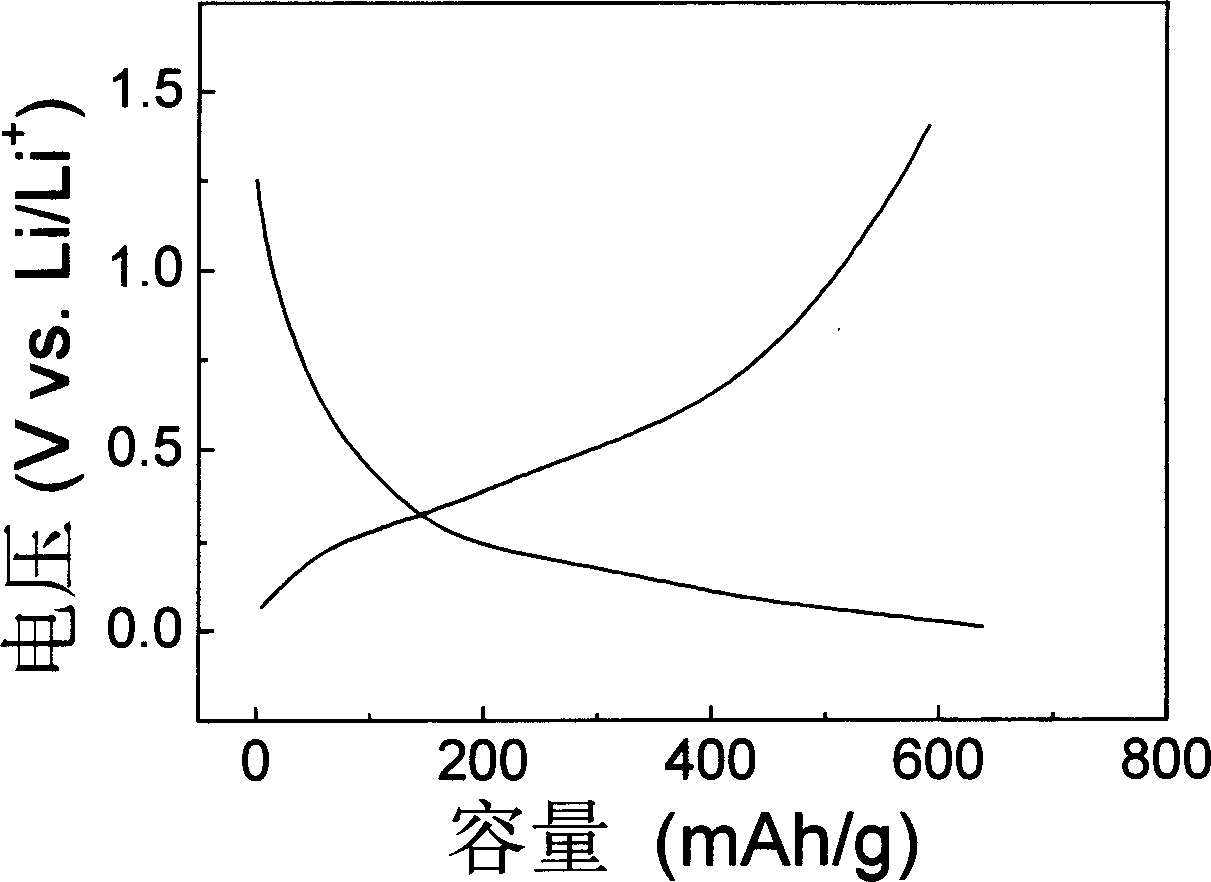

Embodiment 2

[0023] Embodiment 2. Preparation of nanoporous silicon / copper / mesophase carbon microsphere composite negative electrode material for lithium ion battery:

[0024] (1) Mix 1 g of silicon oxide powder and 0.6 g of aluminum powder in an argon atmosphere at room temperature at a mass ratio of 1:0.6, place them in a stainless steel ball mill jar equipped with an O-ring, put stainless steel balls, and keep The argon atmosphere in the tank, the rotating speed of the high-energy ball mill is 400 rpm, and the ball milling time is 15 hours, and about 1.4g of highly dispersed nano-silicon / alumina composites are obtained;

[0025] (2) Mix 0.5g of nano-silicon / alumina composite with 0.45g of metal copper powder in an argon atmosphere at room temperature at a mass ratio of 1:0.9, place them in a stainless steel ball mill jar equipped with an O-ring, and put Stainless steel balls to keep the argon atmosphere in the tank, the speed of the high-energy ball mill is 400 rpm, and the ball milling...

Embodiment 3

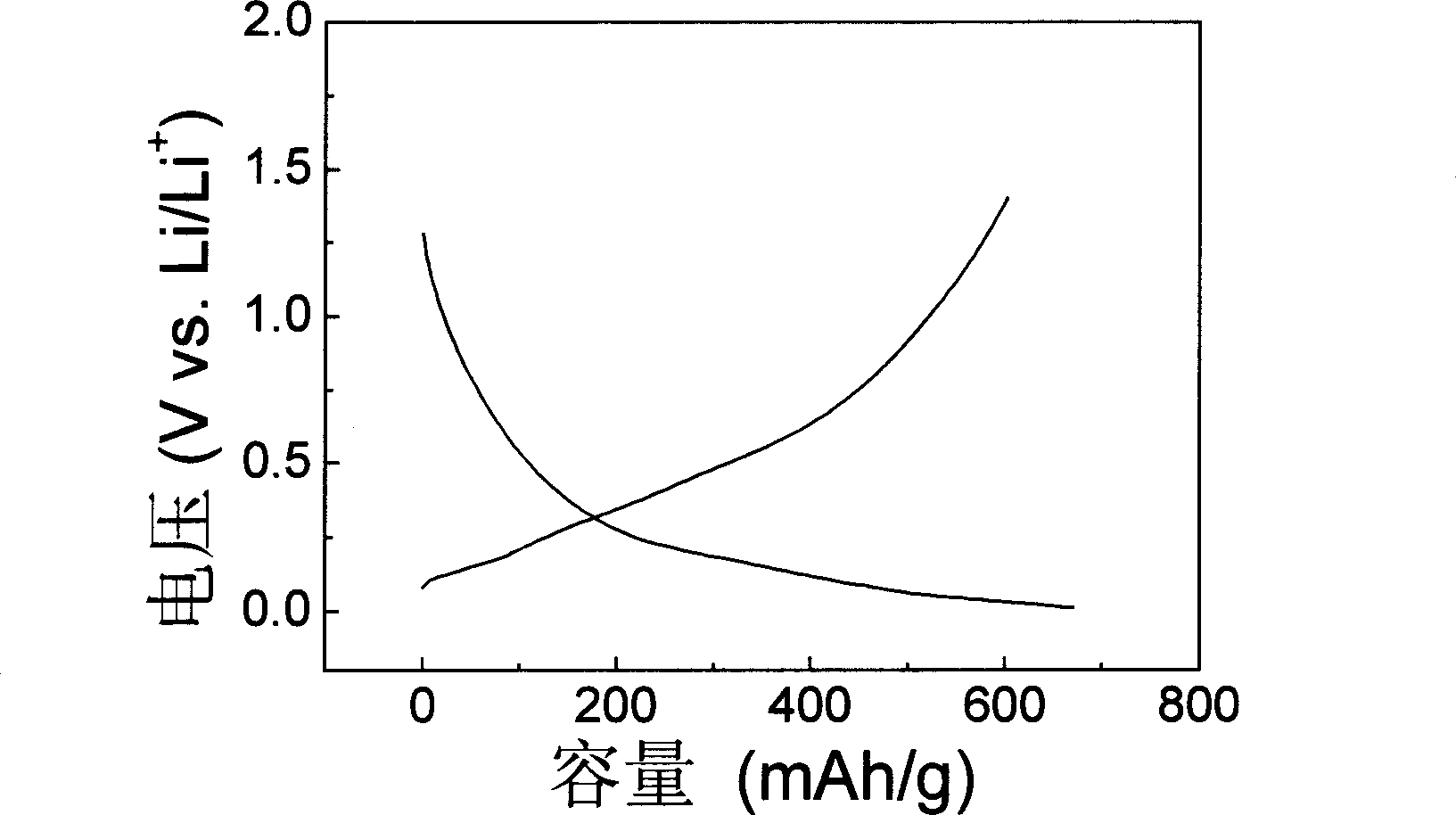

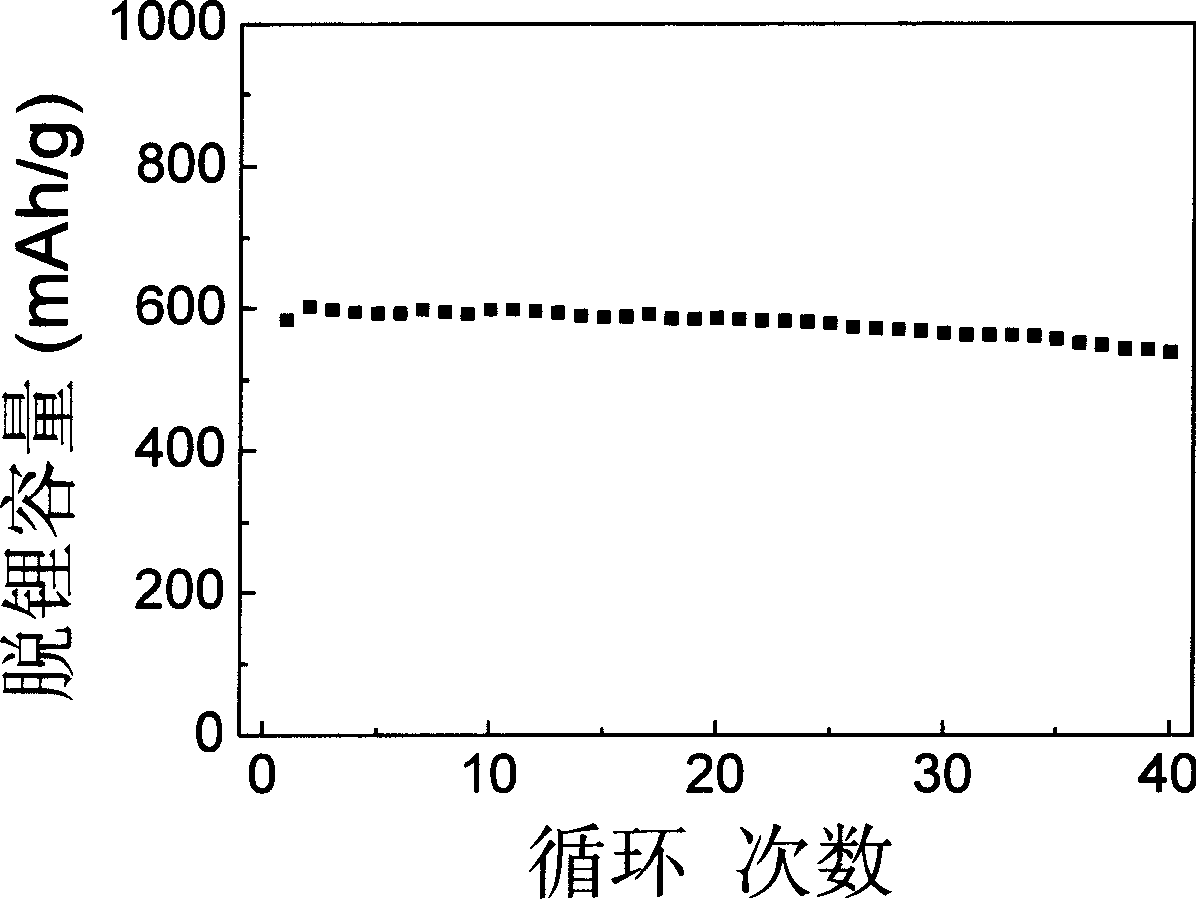

[0029] In the nanoporous silicon / copper / graphite composite powder material that the lithium ion battery that embodiment 1 obtains, add the acetylene black of 30wt% as conductive agent, the PVDF (polyvinylidene fluoride) of 10wt% (PVDF is the 0.02g / mL of PVDF / NMP solution, NMP is N-methylpyrrolidone) as a binder, after being fully stirred evenly, coated on the copper foil, dried in an oven at 80°C, and then coated with Φ12.5mm The punch is punched into a pole piece, and after being pressed at a pressure of 1MPa, it is placed in a vacuum oven at 120°C for 4 hours to dry. Transfer the pole piece to an argon glove box, and make an experimental button battery with metal lithium as the counter electrode, and the electrolyte is 1mol L -1 LiPF 6 / EC:DMC (1:1 volume ratio, EC: ethylene carbonate, DMC: dimethyl carbonate), the test charge and discharge current density is 0.2mA cm -2 , charge-discharge cut-off voltage relative to Li / Li + It is 0.01~1.4V.

[0030] figure 1 It is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com