Negative electrode material, preparation method of material, negative electrode, and battery comprising negative electrode

A negative electrode material and negative electrode technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex preparation process, high preparation cost, and unsuitability for large-scale production, and achieve simple preparation method and high capacity , is conducive to the effect of rapid transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] A preparation method of a negative electrode material, the preparation method comprising the steps of:

[0081] Dissolving the carbon material precursor in the first solvent, adding silicon oxide SiO to the first solvent dissolved with the carbon material precursor x , after mixing, add the second solvent to make the carbon material precursor coated silicon oxide SiO x Precipitation, the precipitated product is dried and then subjected to high temperature treatment to obtain carbon material-coated silicon oxide SiO x , where 1≤x≤2.

[0082] The first solvent is used to dissolve the carbon material precursor, so that the carbon material precursor is fully and uniformly dispersed, and the first solvent is selected from one of dimethylformamide, dimethyl sulfoxide, sulfolane or N-methylpyrrolidone .

[0083] Specifically, the first solvent dissolved with the carbon material precursor and the silicon oxide SiO x The mixing is done by ball milling, the rotational speed r...

Embodiment approach

[0098] Under another preferred embodiment, silicon oxide SiO is added to the first solvent in which the carbon material precursor is dissolved x Add iron powder together with graphene, and then dissolve the iron powder in the product obtained by high temperature treatment with dilute hydrochloric acid solution to obtain a porous negative electrode material, which provides a larger buffer space for the volume effect of the negative electrode material during charging and discharging. At the same time, the contact between the carbon material coating layer and the silicon oxide layer can be improved, thereby improving the electrochemical performance of the negative electrode material. Specifically, the concentration of dilute hydrochloric acid is 1.6-2.4 mol / L, more preferably, the concentration of dilute hydrochloric acid is 2 mol / L.

[0099] Specifically, PAN was dissolved in NMP to form a homogeneous solution, and nano-SiO or SiO 2 Particles, graphene dispersed in a homogeneou...

Embodiment 1

[0143] Dissolve 2.17g of PAN in 12mL of NMP to form a homogeneous solution, 0.8g of SiO 2 Mixed with PAN solution, the mixture was passed through a high-energy ball mill (Pulverisette7, Germany) at a speed of 300rpm, mechanically milled for 36h, using zirconia balls with a diameter of 5 mm, and the weight ratio of zirconia balls to the mixture was 10:1. After ball milling, ethanol was added to the solution to make the PAN-coated SiO 2 precipitation. PAN coated SiO 2 At 1000°C, under the protection of ultra-high-purity nitrogen gas for 3 hours, PAN was pyrolyzed into carbon, the heating rate was 10K / min, and the gas flow rate was 100mL / min.

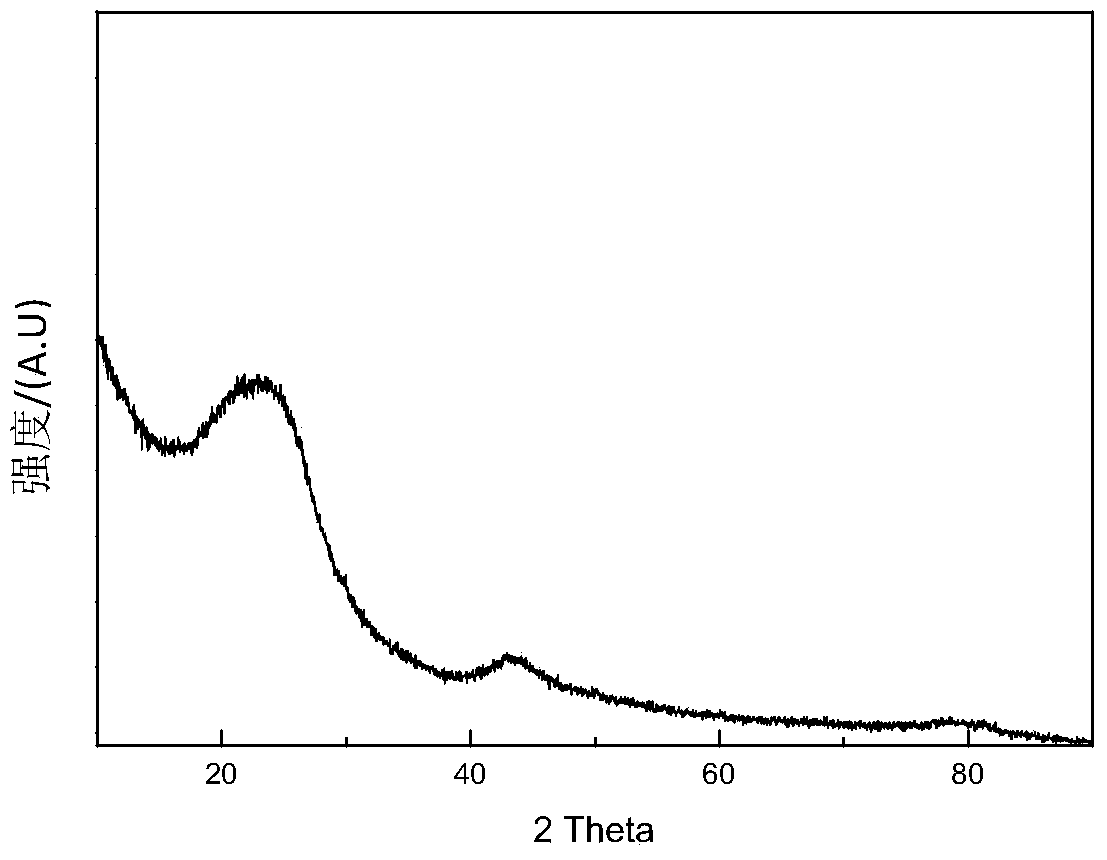

[0144] figure 1 It is the negative electrode material SiO that embodiment 1 provides 2 / C X-ray diffraction pattern. It can be seen from the figure that SiO 2 and C are amorphous.

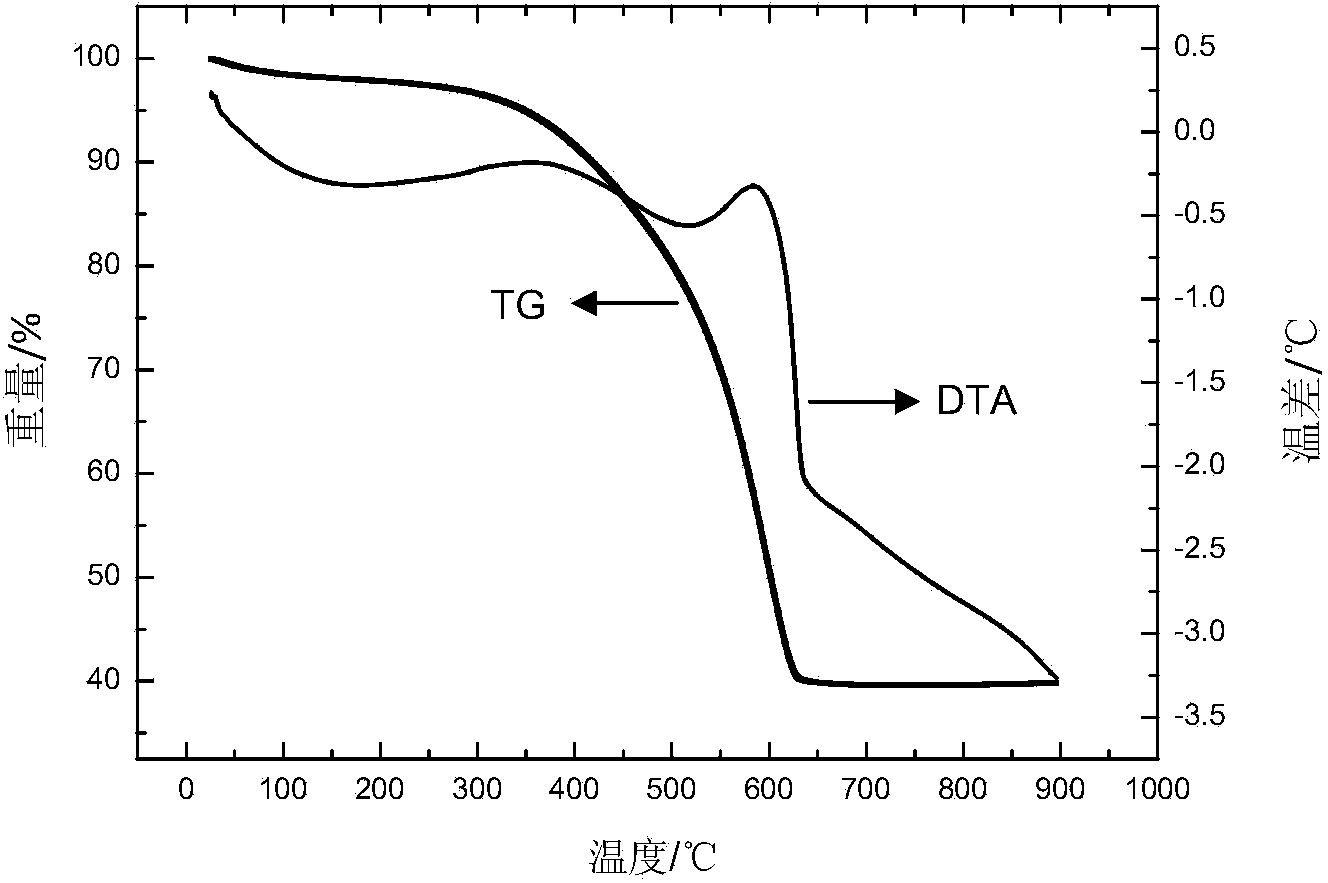

[0145] figure 2 It is the negative electrode material SiO that embodiment 1 provides 2 The thermogravimetric analysis (TG) and differential thermal a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com