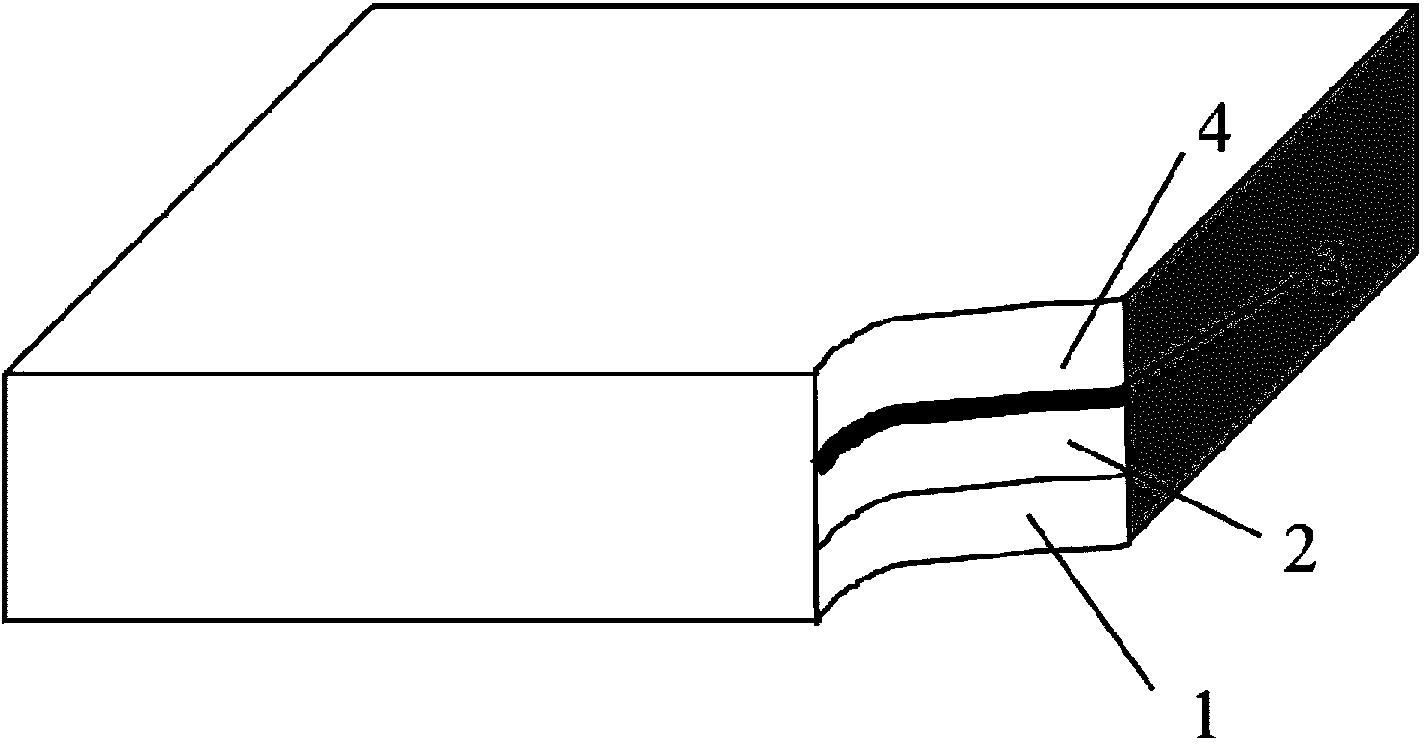

Three-layer electrode structure for alloy anode of lithium ion battery

A lithium-ion battery, alloy negative electrode technology, applied in battery electrodes, structural parts, secondary batteries, etc., can solve the problems of lithium-ion battery alloy negative electrode structure less involved, not suitable for large-scale commercial production, harsh operating conditions, etc. Achieve the effects of low production cost, reduced process difficulty and cost, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

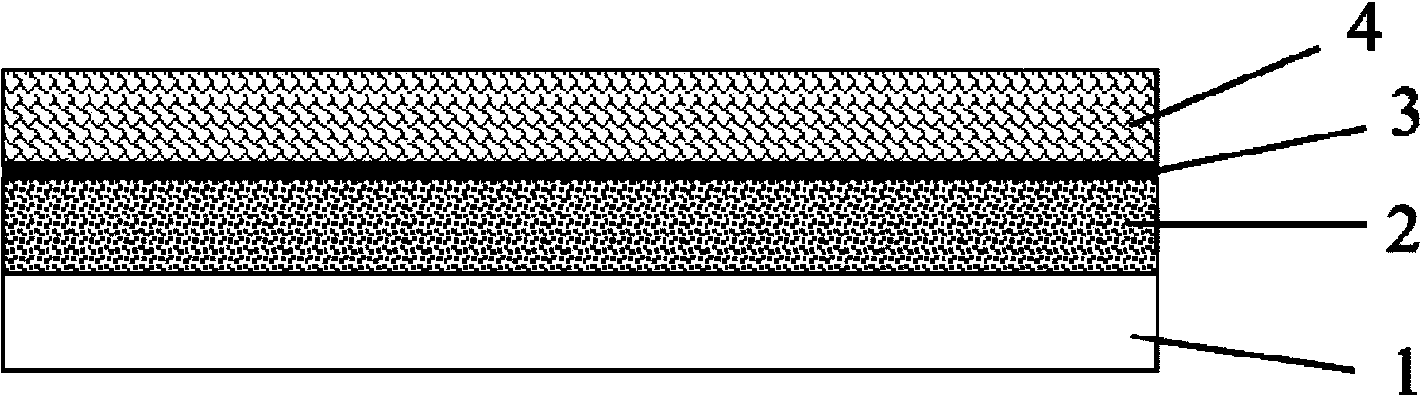

[0036] The preparation method of the deintercalated lithium active material layer is not limited, for example, it can be prefabricated by coating following the traditional lithium ion battery manufacturing process. Specifically, it can be prepared by mixing the lithium-deintercalation active material, the first conductive agent, the first binder, and a certain amount of solvent to form a slurry, coating it on the surface of the current collector layer, drying it in vacuum, and removing the solvent. Deintercalation of the lithium active material layer. Wherein the selection of the solvent is related to the first binder, if the first binder is an organic binder, an organic solvent, such as N-methylpyrrolidone, etc. can be used, if the first binder is a water-based binder, Water can be used as the solvent.

[0037] Using the traditional manufacturing process of lithium-ion batteries avoids the waste of resources, saves costs, and does not need to improve the equipment. The new p...

Embodiment 1

[0061] The preparation of the deintercalated lithium active material layer 2 is the same as that of Comparative Example 1. Mix polypyrrole nanowires, acetylene black, and sodium alginate pre-dissolved in water at a mass ratio of 9:0.5:0.5 to make a slurry, apply it to the deintercalation lithium active material layer 2, and dry it under vacuum at 70°C to make it inert The protective layer 4 is pressed into a three-layer electrode by 6MPa pressure. The battery assembly and test conditions are the same as in Comparative Example 1. The test results are shown in Table 1.

Embodiment 2

[0063] The preparation of the deintercalated lithium active material layer 2 is the same as that of Comparative Example 1. Polypyrrole nanowires, acetylene black and sodium alginate pre-dissolved in water are mixed to form a slurry at a mass ratio of 6:2:2. The preparation of the electrode is the same as Example 1. The battery assembly and test conditions are the same as in Comparative Example 1. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com