Silicon-based composite material and preparation method thereof, silicon-carbon composite material and lithium ion battery

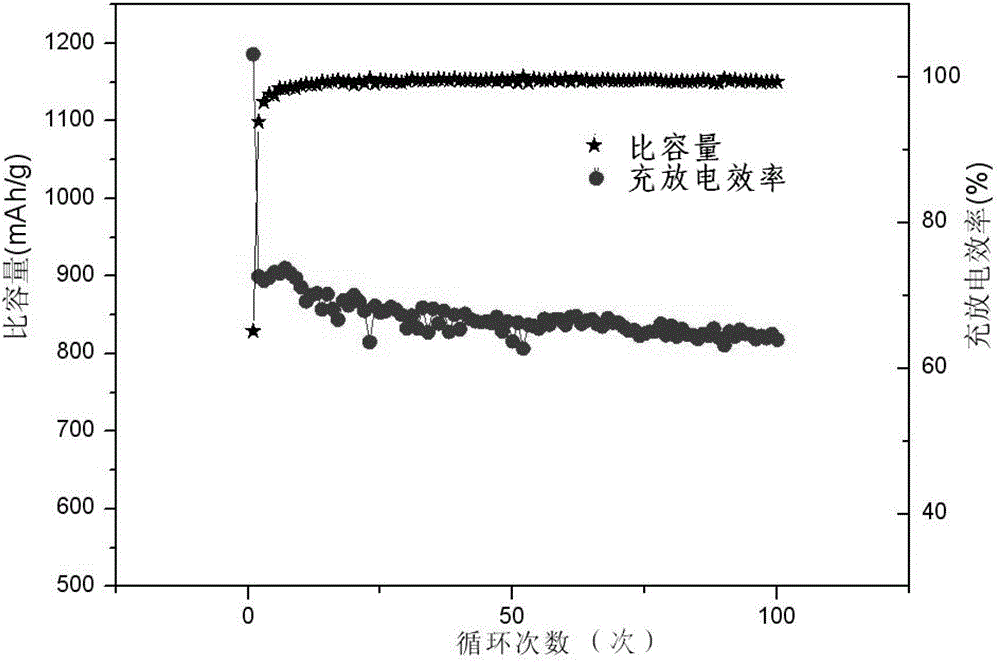

A technology of silicon-based composite materials and composite powders, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as capacity fading, achieve the effects of reduced volume effect, small size, and slow down the speed of capacity fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing a silicon-based composite material, including:

[0033] (1) SiO x (0.5≤x≤1.5) powder mixed with conductive carbon material

[0034] SiO 0.9 Powder (300 mesh) and graphite (150 mesh) as a highly conductive carbon material are added to the ball mill tank of the planetary ball mill, in which SiO 0.9 The mass ratio to graphite is 1 / 9; the ball milling beads are steel balls with a diameter of 20 mm and 60 mm, wherein the mass ratio of the milling beads to the material to be milled is 6; the speed of the ball milling is 400 rpm, and the ball milling is 4 hours to obtain the mixture.

[0035] (2) Coated carbon precursor

[0036] Take the above mixture, add water, wherein the mass ratio of water to mixture is 5; add polyvinyl alcohol and sucrose as carbon precursors, wherein the carbon precursor and SiO 0.9 The mass ratio of the powder is 5, wherein the mass ratio of polyvinyl alcohol to sucrose is 1:1; the above materials are...

Embodiment 2

[0048] This embodiment provides a method for preparing a silicon-based composite material, including:

[0049] (1) SiO x (0.5≤x≤1.5) powder mixed with conductive carbon material

[0050] SiO 1.5 (300 mesh) and carbon nanotubes (150 mesh) as a highly conductive carbon material are added to the ball mill tank of the planetary ball mill, in which SiO 1.5 The mass ratio to carbon nanotubes is 0.5; the ball milling beads are steel balls with a diameter of 20mm and 60mm, wherein the mass ratio of the milling beads to the material to be milled is 6; the speed of the ball milling is 300 rpm, and the ball milling is 2h to obtain the mixture.

[0051] (2) Coated carbon precursor

[0052] Take the above mixture, add water, wherein the mass ratio of water to mixture is 12; add sucrose as a carbon precursor, wherein sucrose and SiO 1.5 The mass ratio of the powder is 3; the above materials are stirred evenly to obtain a suspension, and the suspension is spray-dried, wherein the tempera...

Embodiment 3

[0061] This embodiment provides a method for preparing a silicon-based composite material, including:

[0062] (1) SiO x (0.5≤x≤1.5) powder mixed with conductive carbon material

[0063] SiO 0.5 Powder (300 mesh) and expanded graphite (150 mesh) as a highly conductive carbon material are added to the ball mill tank of the planetary ball mill, in which SiO 0.5 The mass ratio to graphite is 9; the ball milling beads are steel balls with a diameter of 20 mm and 60 mm, wherein the mass ratio of the milling beads to the material to be milled is 6; the speed of the ball milling is 500 rpm, and the ball milling is 8 hours to obtain the mixture.

[0064] (2) Coated carbon precursor

[0065] Take the above mixture, add water, wherein the mass ratio of water to mixture is 7; add glucose as a carbon precursor, wherein glucose and SiO 0.5 The mass ratio of the powder is 0.5; the above materials are stirred evenly to obtain a suspension, and the suspension is spray-dried, wherein the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com