Method for preparing lithium ion battery silicon carbon composite anode material and product prepared by method

A lithium-ion battery and silicon-carbon composite technology, which is applied to battery electrodes, negative electrodes, active material electrodes, etc., can solve the problems of being easily damaged, and achieve the effects of easy large-scale production, optimized quality and structure, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

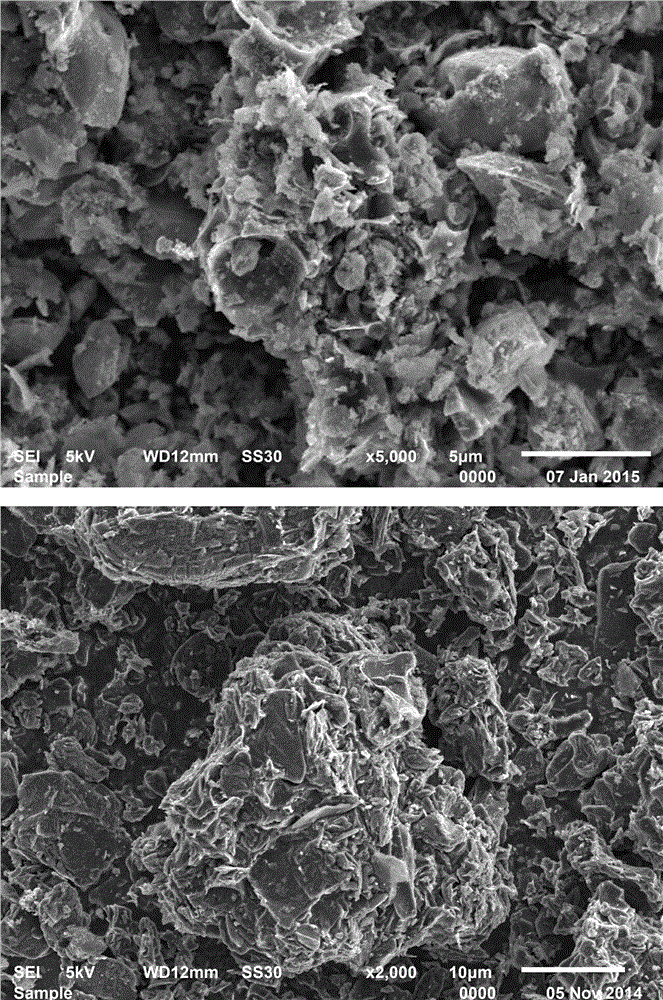

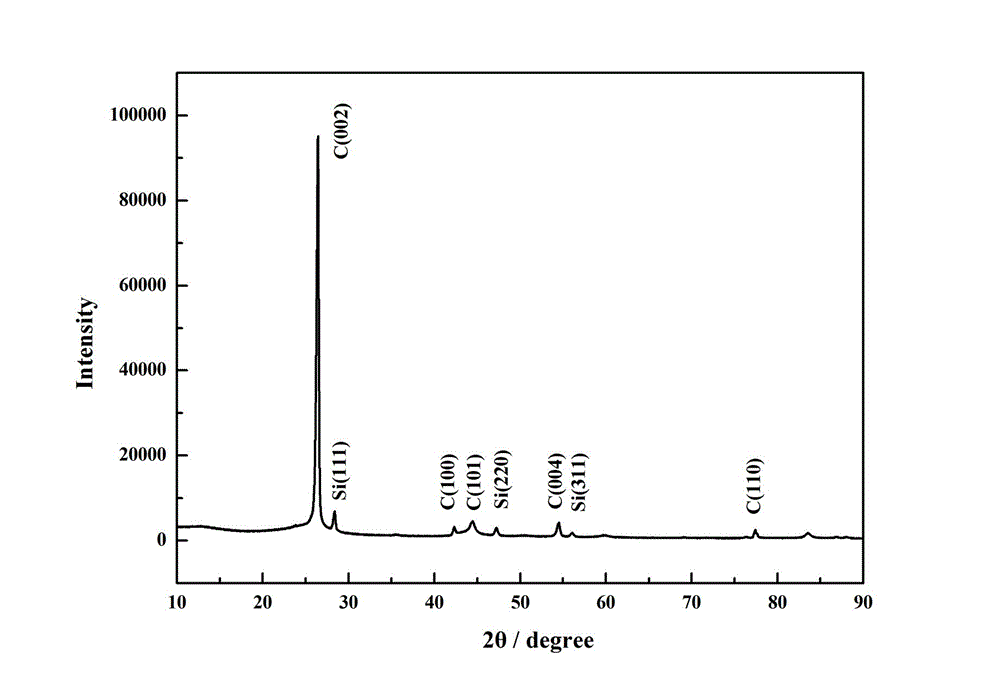

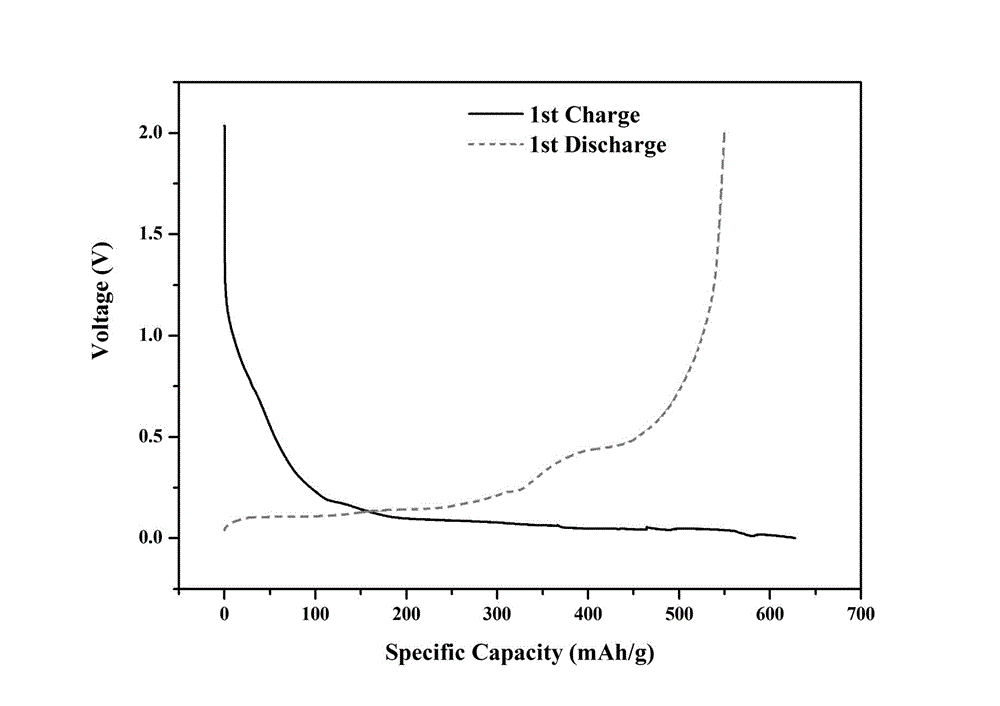

[0039] Add aluminum-silicon alloy powder to excess 8% hydrochloric acid solution, and continue to stir magnetically. After the alloy in the alloy is completely dissolved, wash it with deionized water three times, put it in HF solution and stir for 2 hours, and then use deionized water several times. Wash and dry the material in vacuum, the drying time is 8 hours, the drying temperature is 80°C, and then placed in an organic solution for dispersion, magnetically stirred for 2 hours, and then added asphalt for stirring (the mass ratio of asphalt to silicon is 6:1) , the stirring time is 2 hours, and then artificial graphite is added for stirring for 4 hours (the mass ratio of silicon and artificial graphite is 1:15). Carry out carbonization in a carbonization furnace, the carbonization temperature is 1000°C, the heat preservation time is 6 hours, and the heating rate is 5°C / min. After the carbonization is completed, the material is pulverized and passed through a 200-mesh sieve. ...

Embodiment 2

[0042] Add iron-silicon alloy powder to excess 8% hydrochloric acid solution, and continue to stir magnetically. After the alloy in the alloy is completely dissolved, wash it with deionized water three times, put it in HF solution and stir for 2 hours, and then use deionized water several times. Wash and dry the material in vacuum, the drying time is 8 hours, the drying temperature is 80°C, and then placed in an organic solution for dispersion, magnetically stirred for 2 hours, and then added asphalt for stirring (the mass ratio of asphalt to silicon is 6:1) , the stirring time is 2h, and then artificial graphite is added for stirring for 4h (the mass ratio of silicon and artificial graphite is 1:15). Carry out carbonization in a carbonization furnace, the carbonization temperature is 1000°C, keep warm for 6 hours, and the heating rate is 5°C / min. After the carbonization is completed, crush the material and pass through a 200-mesh sieve. Then put the sieved product in absolute...

Embodiment 3

[0045]Add the manganese-silicon alloy powder into excess 8% hydrochloric acid solution, and keep magnetically stirring until the alloy in the alloy is completely dissolved, wash it with deionized water three times, put it in HF solution and stir for 2 hours, and then use deionized water several times Wash and dry the material in vacuum, the drying time is 8 hours, the drying temperature is 80°C, and then placed in an organic solution for dispersion, magnetically stirred for 2 hours, and then added asphalt for stirring (the mass ratio of asphalt to silicon is 6:1) , the stirring time is 2 hours, and then artificial graphite is added for stirring for 4 hours (the mass ratio of silicon and artificial graphite is 1:15). Carry out carbonization in a carbonization furnace, the carbonization temperature is 1000°C, the heat preservation time is 6 hours, and the heating rate is 5°C / min. After the carbonization is completed, the material is pulverized and passed through a 200-mesh sieve....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com