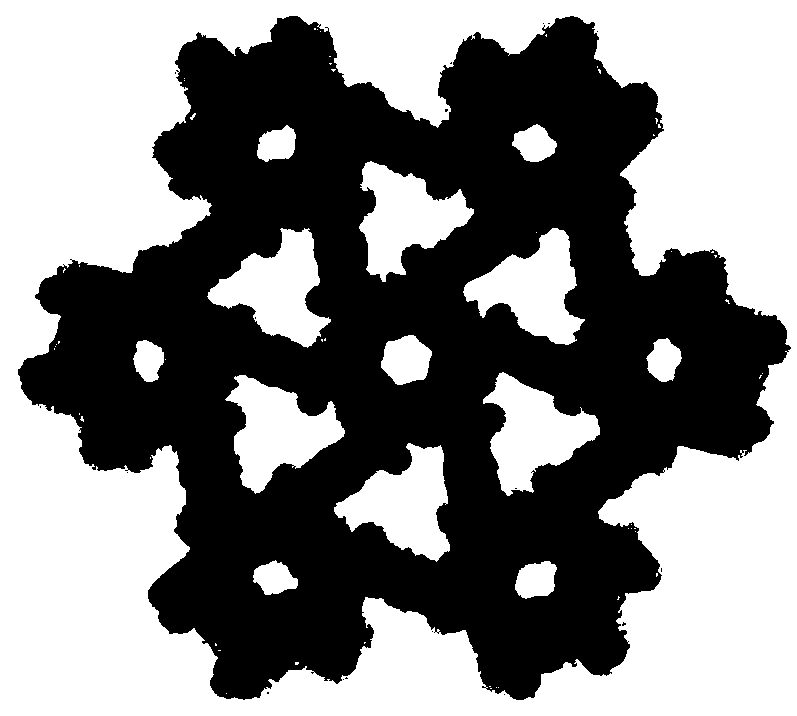

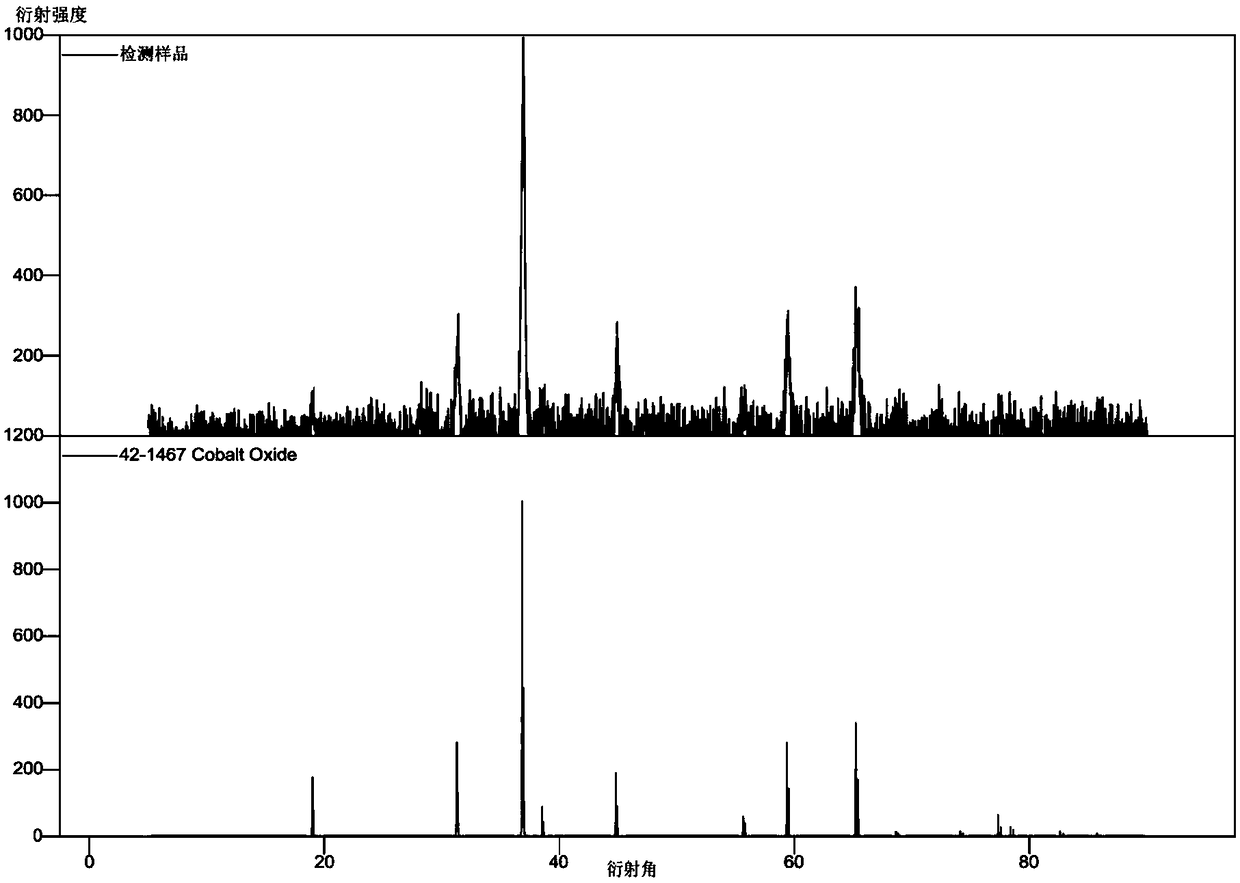

Method of in-situ synthesis of porous nano Co3O4/C anode material

A technology of cobalt tetroxide and carbon anode material, applied in the field of electrochemistry, can solve the problems of insufficient lithium storage performance of anode materials, and achieve the effects of good cycle performance, high specific capacity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

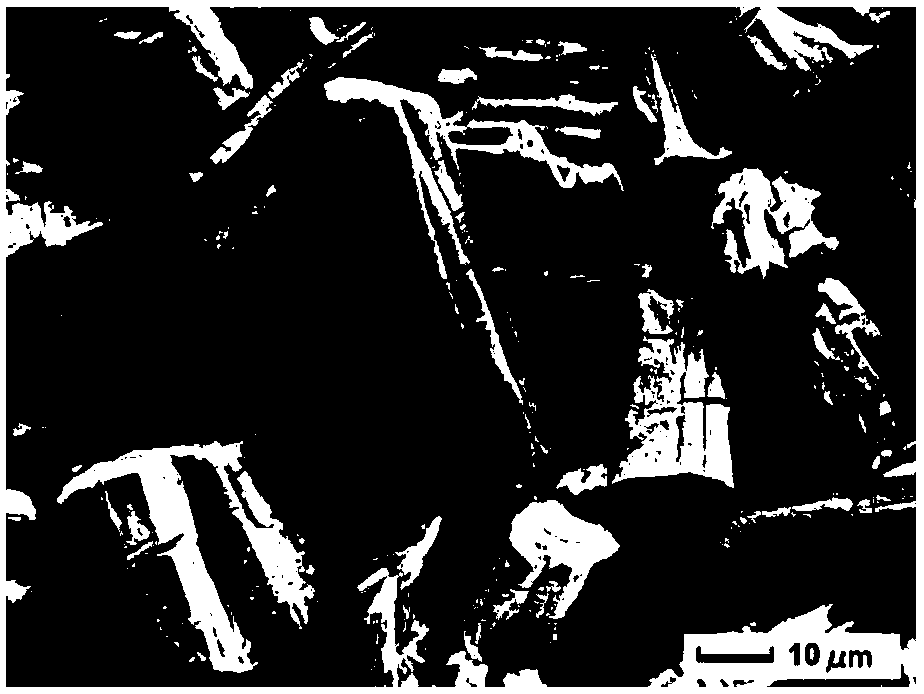

Embodiment 1

[0032] 1. 0.1mol of H 2 ndc, 0.4mol of Co(NO 3 ) 2 ·6H 2 O, 0.1mol Ce(NO 3 ) 3 ·6H 2 O with 6 mL DMF and 2 mL H 2 O was weighed in turn and put into a 25mL tetrafluoroethylene reactor liner, and loaded into a stainless steel reactor for compaction and tightening. Put the above reaction kettle into a blast drying oven, raise it to 100°C for 1 hour at room temperature, keep this temperature for 72 hours, and then drop it to room temperature within 72 hours by means of uniform cooling. Take out the reaction kettle, wash the obtained product with DMF for 1-2 times, put it into an ultrasonic instrument and wash it for 15 minutes, take it out, filter out the pink precipitate, wash it with methanol three times, seal it and soak it in methanol for 3 days. After 3 days, put it into a vacuum drying oven for drying. The drying step is to raise the temperature from room temperature to 80°C for 2 hours within 30 minutes, and then rise to 100°C for 30 minutes and hold it for 10 hour...

Embodiment 2

[0039] 1. 0.1mol of H 2 ndc, 0.4mol of Co(NO 3 ) 2 ·6H 2 O, 0.1mol Ce(NO 3 ) 3 ·6H 2 O with 4 mL DMF and 1 mL H 2 O was weighed in turn and put into a 25mL tetrafluoroethylene reactor liner, and loaded into a stainless steel reactor for compaction and tightening. Put the above reaction kettle into a blast drying oven, raise it to 100°C for 1 hour at room temperature, keep the temperature for 72 hours, and then cool it down to room temperature for about 72 hours in a uniform cooling method. Take out the reaction kettle, wash the obtained product with DMF for 1-2 times, put it into an ultrasonic instrument for 30 minutes, take it out, filter out the pink precipitate, wash it with methanol three times, seal it and soak it in methanol for 3 days. After 3 days, put it in a vacuum drying oven for drying. The drying step is to raise the temperature from room temperature to 100°C within 30 minutes and keep it warm for 10 hours, and then rise to 130°C after 30 minutes and keep ...

Embodiment 3

[0042] 1. 0.1mol of H 2 ndc, 0.4mol of Co(NO 3 ) 2 ·6H 2 O, 0.1mol Ce(NO 3 ) 3 ·6H 2 O with 8 mL DMF and 3 mL H 2 O was weighed in turn and put into a 25mL tetrafluoroethylene reactor liner, and loaded into a stainless steel reactor for compaction and tightening. Put the above reaction kettle into a blast drying oven, raise it to 100°C for 1 hour at room temperature, keep the temperature for 72 hours, and then cool it down to room temperature for about 72 hours in a uniform cooling method. Take out the reaction kettle, wash the obtained product with DMF for 1-2 times, put it into an ultrasonic instrument for 20 minutes, take it out, filter out the pink precipitate, wash it with methanol three times, seal it and soak it in methanol for 3 days. After 3 days, put it in a vacuum drying oven for drying. The drying step is to raise the temperature from room temperature to 90°C within 30 minutes and keep it warm for 6 hours, and then rise to 110°C after 30 minutes and keep it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com