Lithium ion battery positive pole pieceand preparation method thereof

A lithium-ion battery, positive electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor dispersion effect, reduced battery cycle performance, and poor electrode conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method for a lithium-ion battery positive plate, characterized in that it comprises the steps of:

[0034] S1. Add the proportion of the material installation formula required for the conductive coating layer 2 into the agitator, and adjust the homogenate dispersion to a viscosity of 500-1000mPa.s to obtain a conductive paste, which is ready for use;

[0035] S2. Add the ratio of the material installation formula required for the active slurry layer 3 into the agitator, and adjust the homogenate dispersion to a viscosity of 4000-6000mPa.s to obtain the active material slurry for use;

[0036] S3, coating the conductive coating layer 2 obtained in S1 on the surface of the positive electrode current collector 1 and baking for later use;

[0037] S4. Coating the active slurry obtained in S2 on the surface of the conductive coating layer 2, baking and rolling to obtain the positive electrode sheet.

[0038] In S3, the baking temperature is 80-105°C, and the b...

Embodiment 1

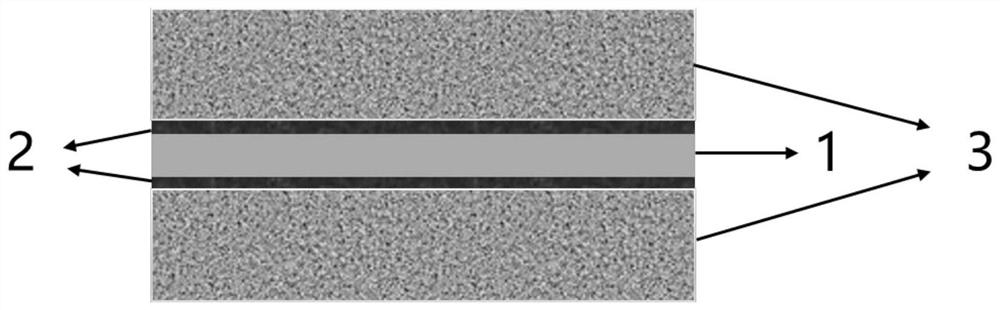

[0041] as shown figure 1 A positive electrode sheet of a lithium ion battery is shown, including a positive current collector 1, the surface of the positive current collector is coated with a conductive coating layer 2, and the conductive coating layer is made of the following components in mass percentage: conductive carbon black 0.0543kg, 0.0109kg of polyvinylidene fluoride, 0.054kg of ethanol, 0.054kg of acetone, and 0.478kg of deionized water; the surface of the conductive coating layer 2 is coated with an active slurry layer 3, and the active slurry layer is made of the following components in mass percentage Cheng: Anda (trademark) LiFePO 4 Active material 10.5kg, German side (industry trademark) LiFePO 4 Active material 4.5kg, conductive agent (0.237kg conductive carbon black SP+0.126kg LiTX300+0.079kg ECP), binder (0.313kg polyvinylidene fluoride HSV900+0.034kg polyvinylidene fluoride HSV1800). When homogenizing, add part of N-methylpyrrolidone to adjust the viscosit...

Embodiment 2

[0048] as shownfigure 1 A positive electrode sheet of a lithium ion battery is shown, including a positive current collector 1, the surface of the positive current collector is coated with a conductive coating layer 2, and the conductive coating layer is made of the following components in mass percentage: conductive carbon black 0.0543kg, 0.0109kg of polyvinylidene fluoride, 0.054kg of ethanol, 0.054kg of acetone, and 0.478kg of deionized water; the surface of the conductive coating layer 2 is coated with an active slurry layer 3, and the active slurry layer is made of the following components in mass percentage Cheng: Anda (trademark) LiFePO 4 Active material 10.5kg, German side (industry trademark) LiFePO 4 Active material 4.5kg, conductive agent (0.158kg conductive carbon black SP+0.158kg LiTX300+0.126kg ECP), binder (0.278kg polyvinylidene fluoride HSV900+0.069kg polyvinylidene fluoride HSV1800). When homogenizing, add part of N-methylpyrrolidone to adjust the viscosity....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com