Secondary battery and electronic device

A technology for secondary batteries and carbon nanotube bundles, applied in secondary batteries, secondary battery manufacturing, battery electrodes, etc., can solve the problem of battery rate performance, deterioration of charging performance, increase in DC internal resistance of batteries, and damage to conductive networks, etc. problem, to achieve the effect of improved battery life, improved cycle life, strong conductive network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0083] In the positive electrode preparation method, including:

[0084] Specifically, the preparation of the positive electrode sheet includes:

[0085] 1) Mix the positive electrode active material, carbon material, binder, and solvent (such as deionized water, N-methylpyrrolidone) evenly to make a slurry;

[0086] 2) coating the slurry in step 1) on the target area of the current collector;

[0087] 3) After drying the solvent, obtain a primary pole piece coated with a positive electrode active material layer;

[0088] 4) The primary pole piece obtained in step 3) is dried and rolled to obtain a positive pole piece.

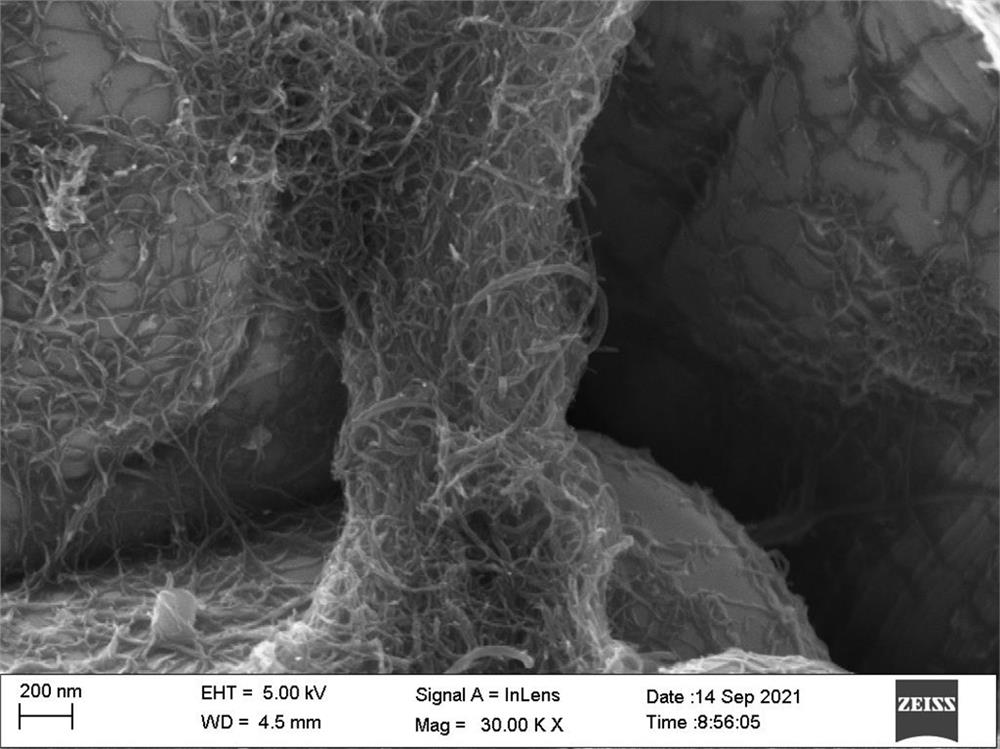

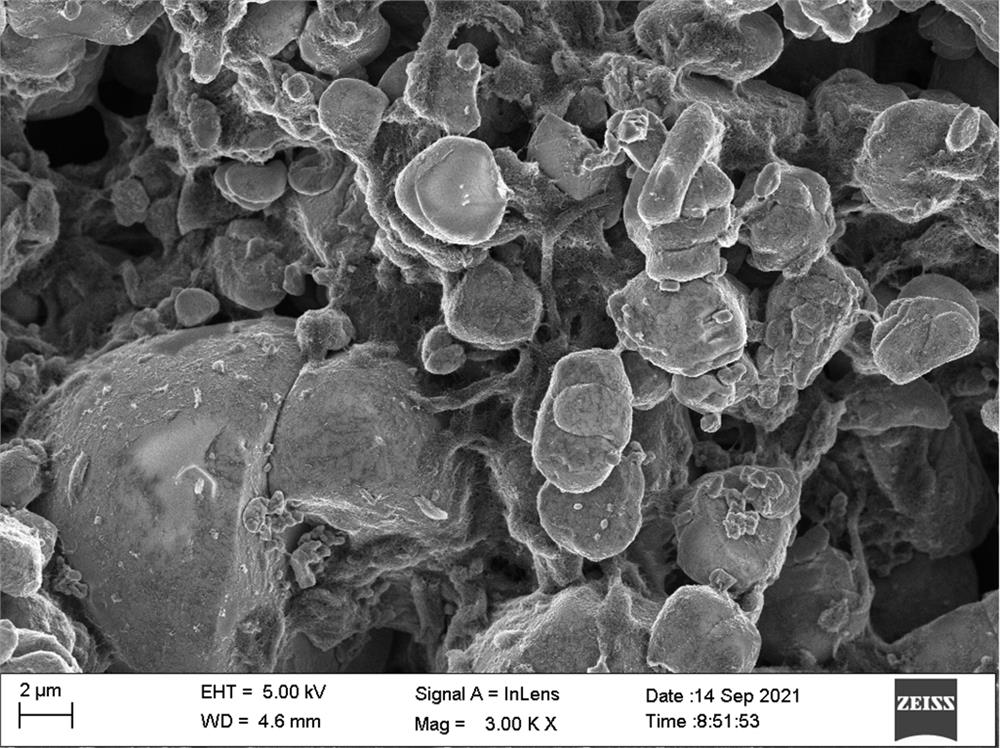

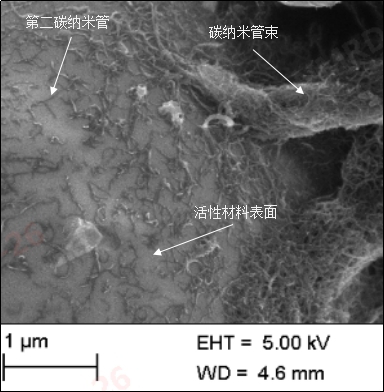

[0089] Specifically, the carbon material may be a conductive agent made by mixing carbon nanotube bundles and at least one of conductive carbon black and second carbon nanotubes.

[0090] Optionally, the positive electrode active material layer includes a positive electrode active material, carbon nanotube bundles, second carbon nanotubes and a binder.

...

Embodiment approach

[0093] The parameters of the carbon nanotube bundles in each example are shown in Table a. The carbon nanotube bundle can be purchased from the market, as long as it meets the parameters of the carbon nanotube bundle of the present application.

[0094] Table a Parameters of carbon nanotube bundles

[0095]

[0096] The parameters of the second carbon nanotubes in each example are shown in Table b. The carbon nanotubes can be purchased from the market, as long as they meet the parameters of the second carbon nanotubes of the present application.

[0097] Table b Parameters of the second carbon nanotubes

[0098] .

Embodiment 1-1

[0100] S100, the LiCoO 2 ,1 # Carbon nanotube bundles and PVDF are mixed according to the ratio of 98.2:0.5:1.3 to prepare a slurry;

[0101] S200, coating the slurry on the target area of the current collector (aluminum foil);

[0102] S300, drying at 120° C. to obtain a primary pole piece coated with an active material layer;

[0103] S400, drying and rolling the primary pole piece obtained in step S300 to obtain the positive pole piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com