Preparation method and application of lignin-based hard carbon

A lignin-based, lignin-based technology, applied in the field of lithium-ion capacitors, can solve problems such as insufficient pulse discharge capacity, high manufacturing cost, and complicated process, and achieve the effects of first-time efficiency, low cost, and simple preparation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

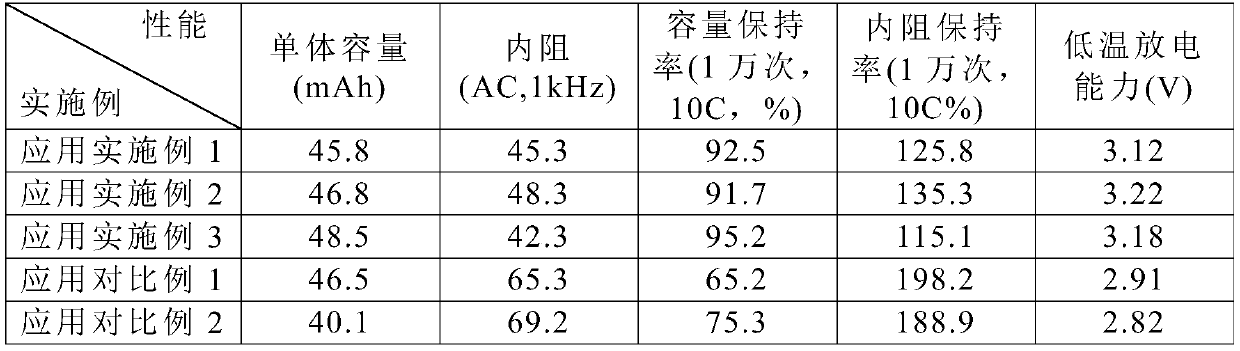

Examples

Embodiment 1

[0043] (1) Pretreatment: Add 100g of sodium lignosulfonate to 500g of 2% sodium hydroxide solution with a mass concentration of 0.5 to 1.5h for ultrasonic treatment, the weight ratio of sodium lignosulfonate to sodium hydroxide solution is 1:5 , then the product after the alkali treatment is filtered, 20g hydrochloric acid is added in the filtrate, after standing until the solution is layered, the lower layer of precipitate is taken, and the steps of the above-mentioned pretreatment (alkaline treatment, acid treatment and washing) are repeated twice. The obtained precipitate was dried at 80° C. for 12 hours to obtain 65 g of sodium lignosulfonate after removal of impurities for use.

[0044] (2) Preparation of lignin nanoparticle precursor: Take 100g of acetone and 100g of deionized water and mix evenly to make an acetone aqueous solution, add 10g of pretreated sodium lignosulfonate to the acetone aqueous solution, and form lignin after fully dissolving for 4 hours Nanoparticl...

Embodiment 2

[0047](1) Pretreatment: Add 100g of sodium lignosulfonate to 500g of 2% sodium hydroxide solution with a mass concentration of 0.5 to 1.5h for ultrasonic treatment, the weight ratio of sodium lignosulfonate to sodium hydroxide solution is 1:5 , then the product after the alkali treatment is filtered, 20g hydrochloric acid is added in the filtrate, after standing until the solution is layered, the lower layer of precipitate is taken, and the steps of the above-mentioned pretreatment (alkaline treatment, acid treatment and washing) are repeated twice. The obtained precipitate was dried at 80° C. for 12 hours to obtain 65 g of sodium lignosulfonate after removal of impurities for use.

[0048] (2) Preparation of lignin nanoparticle precursor: Take 20g of acetone and 100g of deionized water and mix evenly to make an acetone aqueous solution, add 10g of pretreated sodium lignosulfonate to the acetone aqueous solution, and form lignin after fully dissolving for 4 hours Nanoparticle ...

Embodiment 3

[0051] (1) Pretreatment: Add 100g of sodium lignosulfonate to 500g of 2% sodium hydroxide solution with a mass concentration of 0.5 to 1.5h for ultrasonic treatment, the weight ratio of sodium lignosulfonate to sodium hydroxide solution is 1:5 , then the product after the alkali treatment is filtered, 20g hydrochloric acid is added in the filtrate, after standing until the solution is layered, the lower layer of precipitate is taken, and the steps of the above-mentioned pretreatment (alkaline treatment, acid treatment and washing) are repeated twice. The obtained precipitate was dried at 80° C. for 12 hours to obtain 65 g of sodium lignosulfonate after removal of impurities for use.

[0052] (2) Preparation of lignin nanoparticle precursor: Take 30g of acetone and 100g of deionized water and mix evenly to make an acetone aqueous solution, add 10g of pretreated sodium lignosulfonate to the acetone aqueous solution, and form lignin after fully dissolving for 4 hours Nanoparticle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com