Composite conductive agent and preparation method thereof, and lithium-ion battery positive electrode

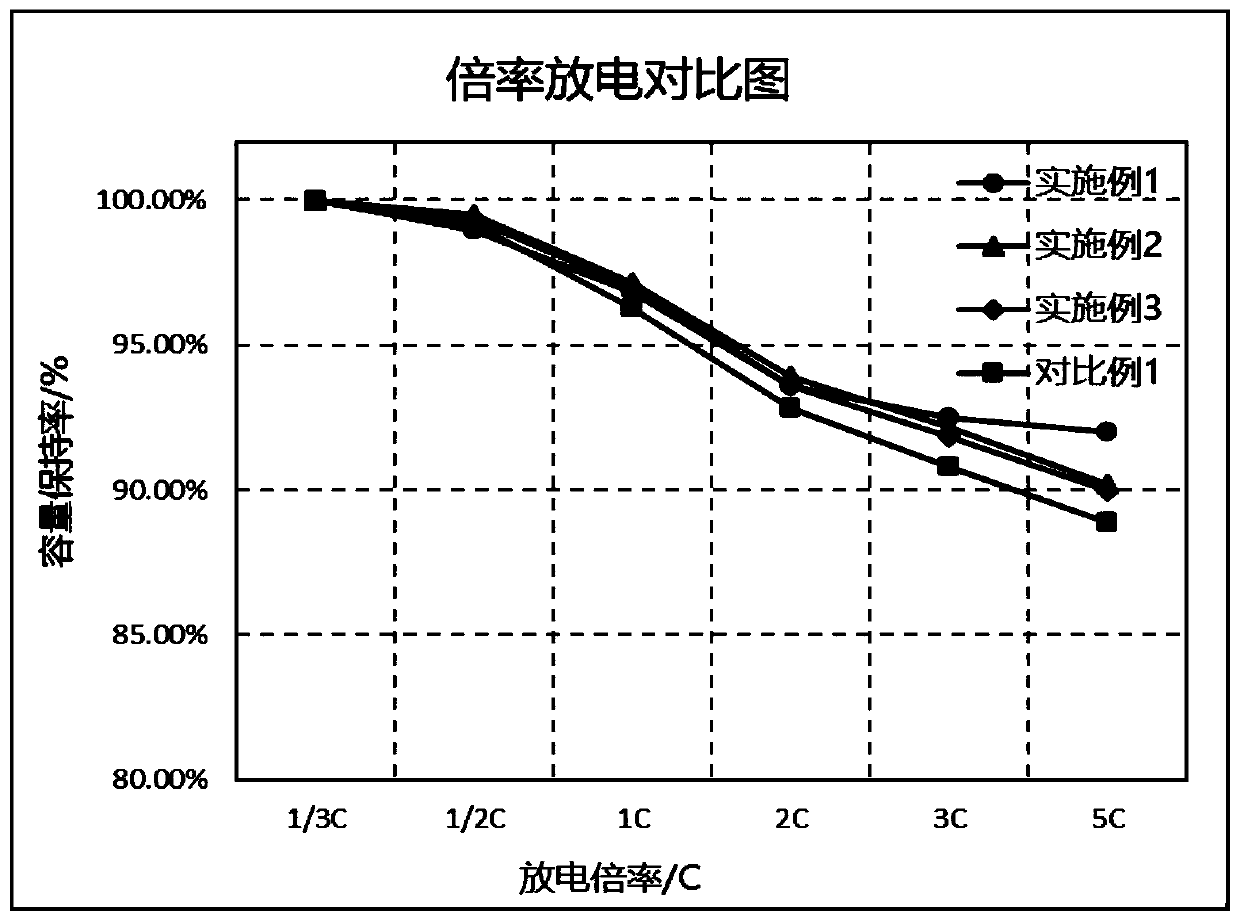

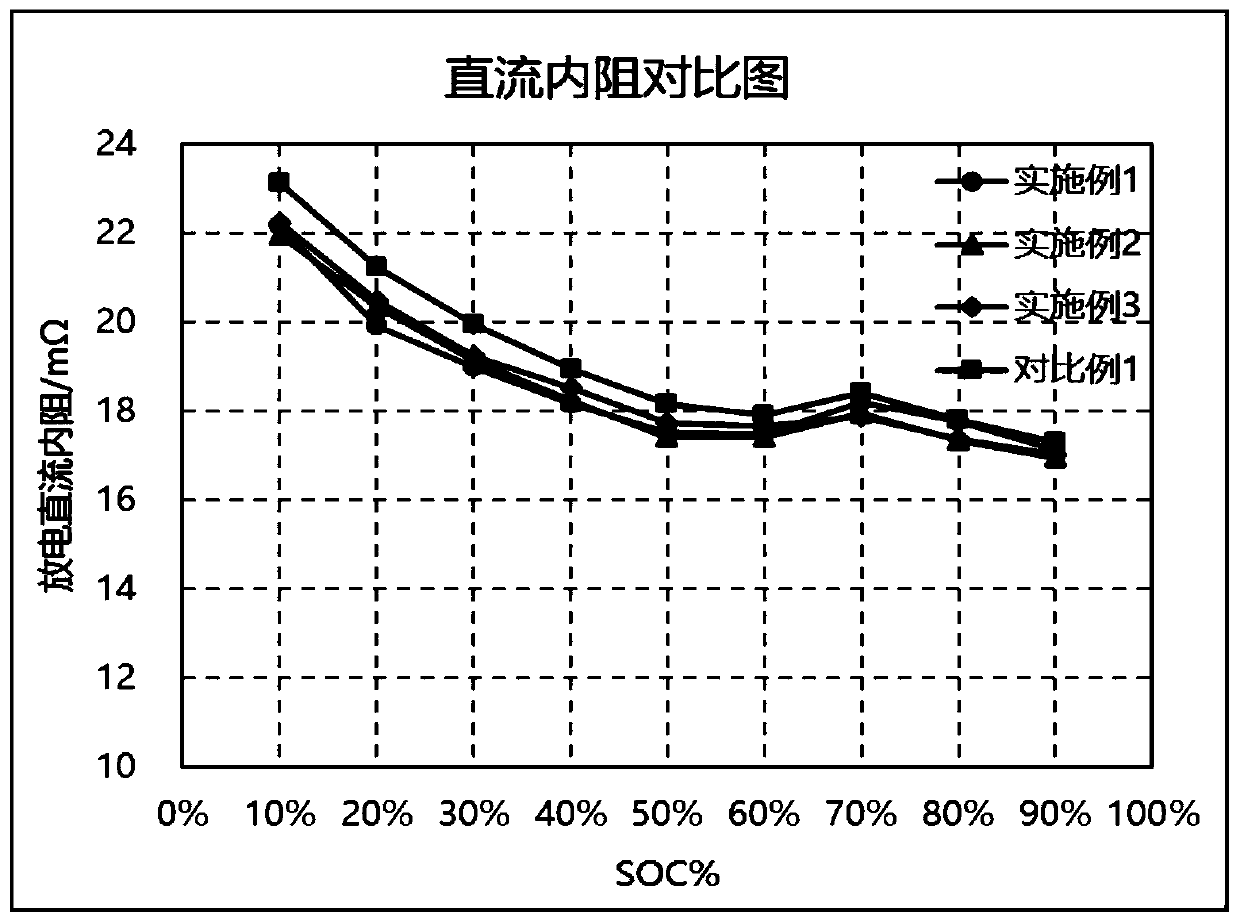

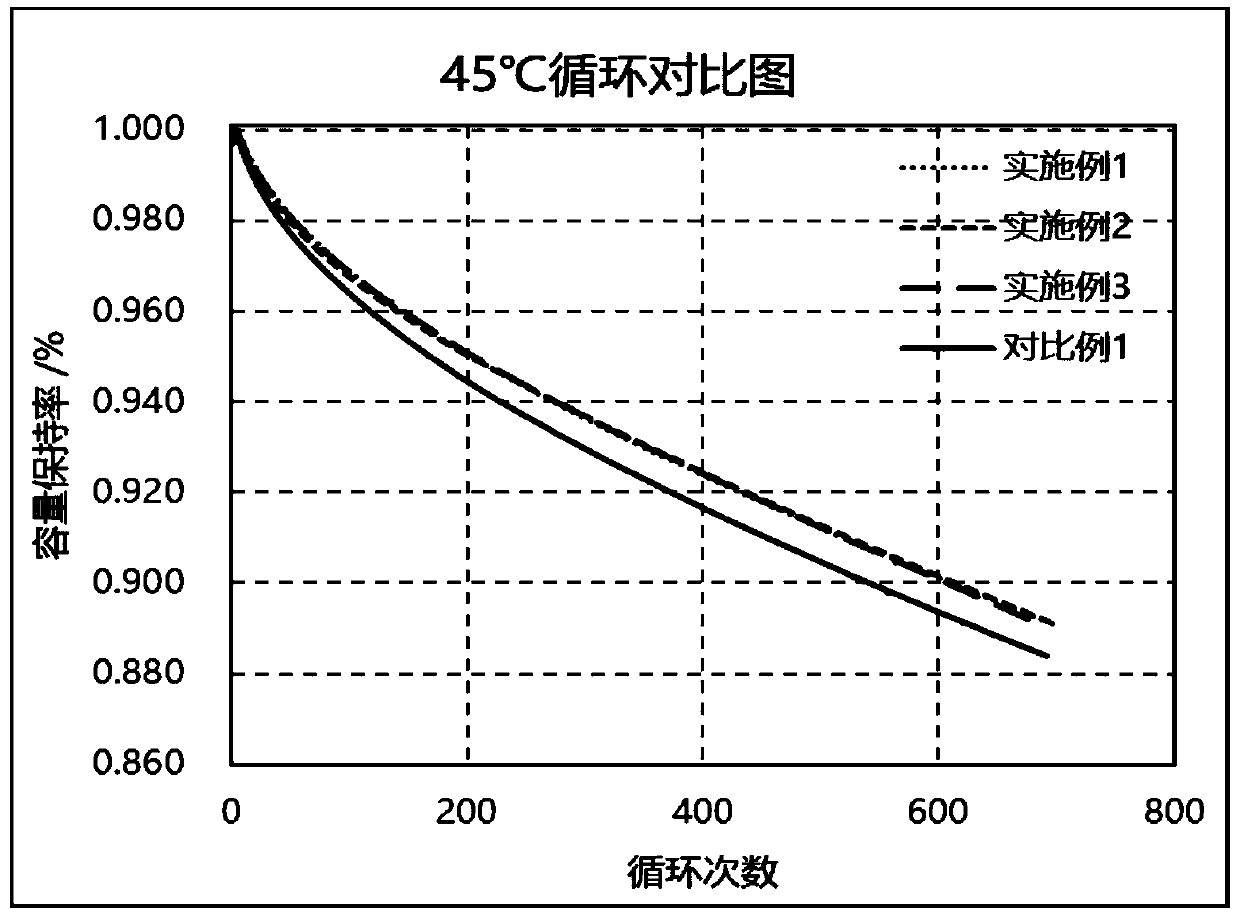

A composite conductive agent and positive electrode technology, which is applied in the direction of non-aqueous electrolyte battery electrodes, battery electrodes, secondary batteries, etc., can solve the problems of battery performance degradation, achieve stable performance, reduce DC internal resistance, and increase gram capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A composite conductive agent, including the following components in weight percentage: 1.6% conductive carbon black, 0.28% carbon nanotube, 0.12% graphene; 0.5% dispersant; 97.5% solvent. Wherein, the dispersant is polyvinylpyrrolidone, and the solvent is N-methylpyrrolidone.

[0029] A preparation method of composite conductive agent, comprising the following steps:

[0030] 1) According to the formula quantity, the composite powder of conductive carbon black, carbon nanotubes and graphene is made by hydrothermal method;

[0031] The hydrothermal method is as follows: add conductive carbon black and deionized water to the hydrothermal kettle, stir at room temperature for 15 minutes, add carbon nanotubes and continue stirring at room temperature for 10 minutes, add graphene and continue stirring at room temperature for 30 minutes, and then stir at 180 ° C After 3 hours, the obtained product was cooled to room temperature, filtered, washed and dried, put into a tube fur...

Embodiment 2

[0039] A composite conductive agent, comprising the following components in weight percentage: 0.5% conductive carbon black, 0.56% carbon nanotube, 0.24% graphene; 0.8% dispersant; 97.9% solvent. Wherein, the dispersant is polyvinylpyrrolidone, and the solvent is N-methylpyrrolidone.

[0040] A preparation method of composite conductive agent, comprising the following steps:

[0041] 1) According to the formula quantity, the composite powder of conductive carbon black, carbon nanotubes and graphene is made by hydrothermal method;

[0042] The hydrothermal method is as follows: add conductive carbon black and deionized water to the hydrothermal kettle, stir at room temperature for 20 minutes, add carbon nanotubes and continue stirring at room temperature for 20 minutes, add graphene and continue stirring at room temperature for 15 minutes, and then stir at 200 ° C After 4 hours, the obtained product was cooled to room temperature, filtered, washed and dried, put into a tube fu...

Embodiment 3

[0050] A composite conductive agent, comprising the following components in weight percentage: 1.0% conductive carbon black, 0.42% carbon nanotube, 0.18% graphene; 0.7% dispersant; 97.7% solvent. Wherein, the dispersant is polyvinylpyrrolidone, and the solvent is N-methylpyrrolidone.

[0051] A preparation method of composite conductive agent, comprising the following steps:

[0052] 1) According to the formula quantity, the composite powder of conductive carbon black, carbon nanotubes and graphene is made by hydrothermal method;

[0053]The hydrothermal method is as follows: add conductive carbon black and deionized water to the hydrothermal kettle, stir at room temperature for 10 minutes, add carbon nanotubes and continue stirring at room temperature for 15 minutes, add graphene and continue stirring at room temperature for 20 minutes, and then stir at 190°C After 3 hours, the obtained product was cooled to room temperature, filtered, washed and dried, put into a tube furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com