Printed circuit board (PCB) chip layout structure and electronic terminal using the same

A chip layout and electronic terminal technology, applied in the direction of printed circuits connected with non-printed electrical components, can solve the space constraints of chip placement and conductive traces, unfavorable engineer layout and conductive traces, and increase the risk of power supply line interference and other issues to achieve the effect of reducing the risk of mutual interference, enhancing electromagnetic compatibility, and shortening the power supply line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and specific embodiments.

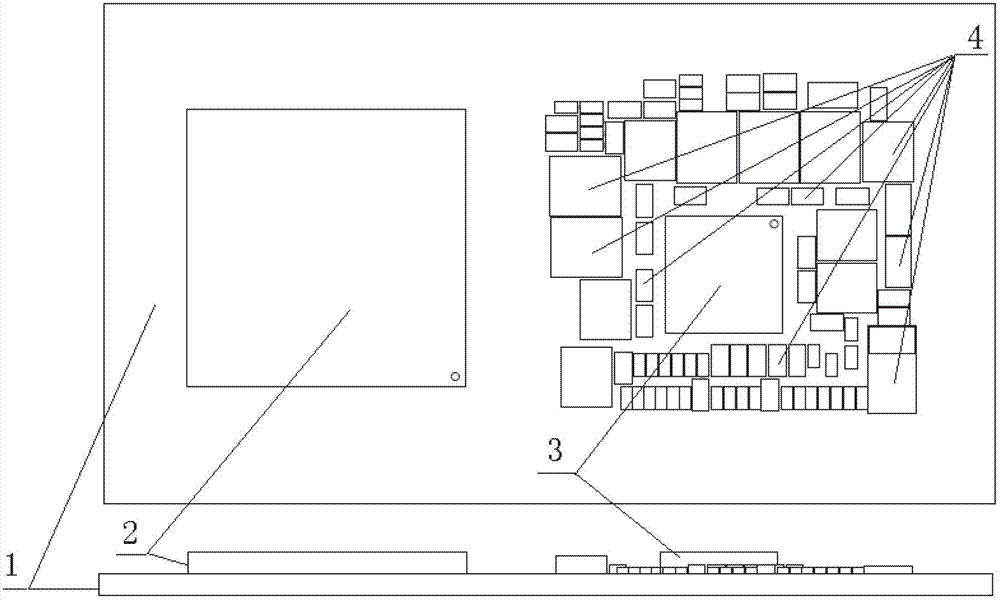

[0023] in figure 1 The CPU 2 and the PMU 3 are arranged on the same side of the PCB 1. The capacitors, inductors, and resistors 4 around the PMU 3 occupy a lot of space, which increases the distance between the CPU 2 and the PMU 3, and electromagnetic interference is easily introduced.

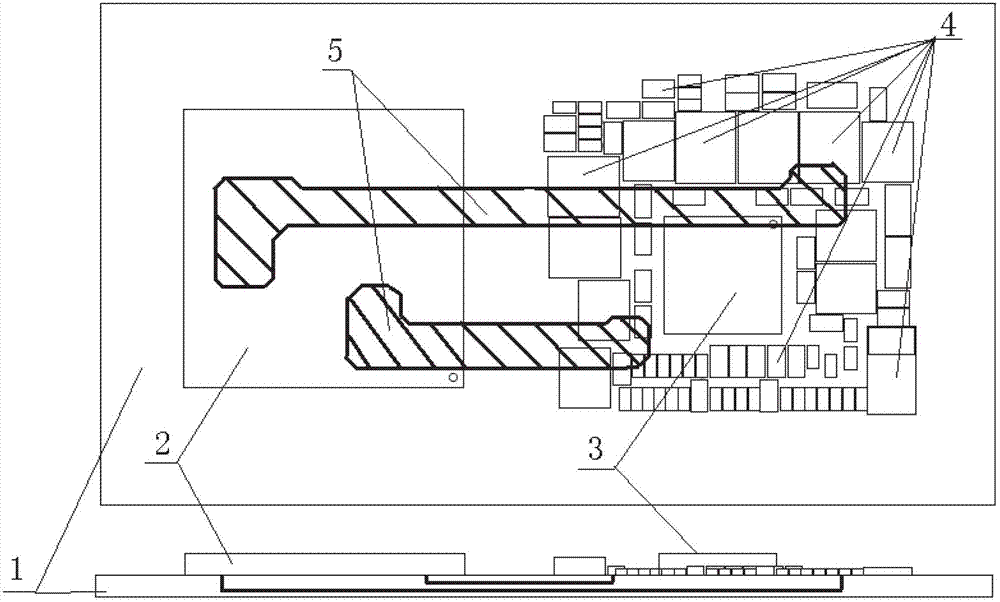

[0024] in figure 2 The conductive trace 5 is connected to the CPU2 and the PMU3, so that the PMU3 supplies power to the CPU2 through the conductive trace 5. It can be seen that the conductive trace 5 is longer, and its AC and DC resistances are large. The power supply is easily unstable and easy to introduce interference.

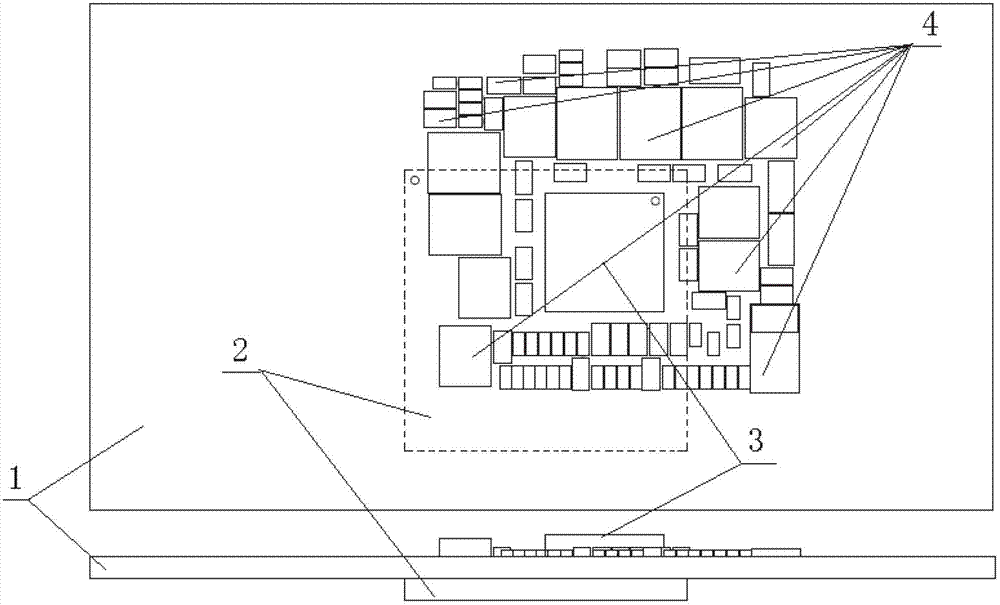

[0025] in image 3 CPU2 is arranged on the back of PMU3 and the projections of the two on the PCB are mostly overlapped, which shortens the distance between CPU2 and PMU3, and at the same time makes full use of the space of PCB1, making the device placement com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com