Composite conductive agent, lithium ion battery positive electrode and lithium ion battery

A technology of composite conductive agent and lithium-ion battery, which is applied in battery electrodes, secondary batteries, electrode carriers/collectors, etc., can solve problems such as the inability to effectively reduce the DC internal resistance of ternary batteries, and achieve improved overcharge performance, distribution Ratio is reasonable, the effect of improving electronic conductivity and ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

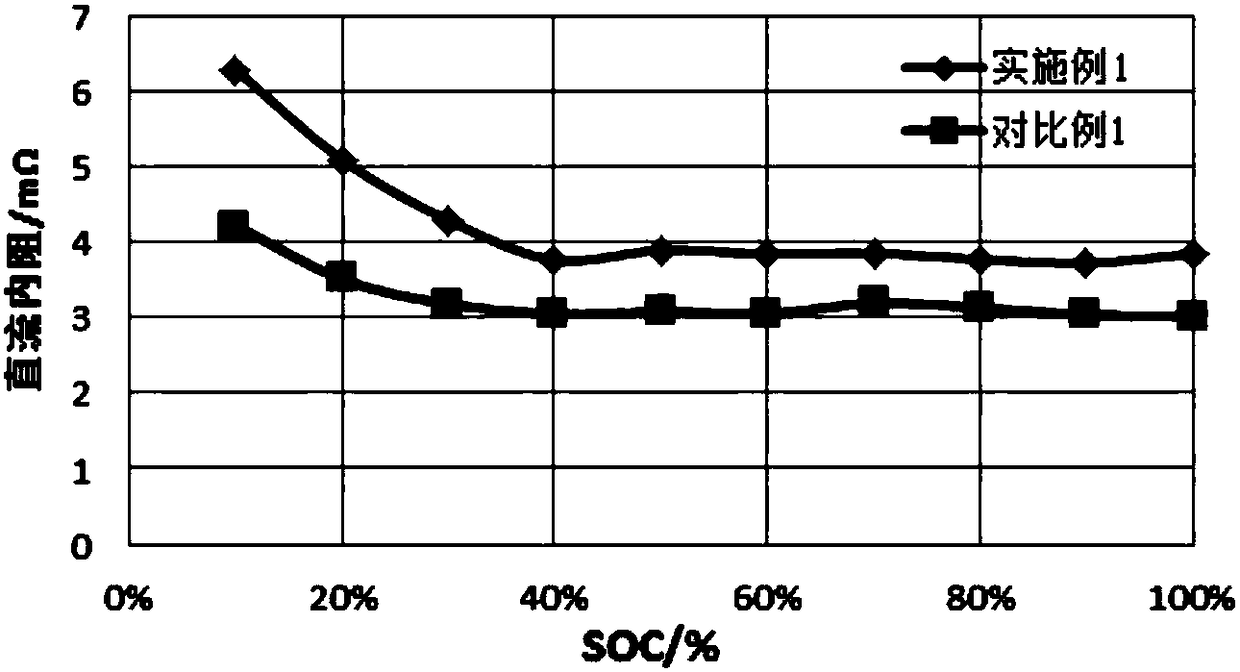

Embodiment 1

[0032] The positive electrode of the lithium ion battery of this embodiment includes copper foil and electrode material layers coated on both sides of the copper foil, the electrode material layer is composed of a positive electrode active material, a binder and a composite conductive agent, and the positive electrode active material is three Element material (LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 ) and lithium manganese iron phosphate, the binder is PVDF, the composite conductive agent is conductive agent SP, KS6 and carbon nanotubes, and the weight ratio of each component is ternary material: lithium manganese iron phosphate: PVDF: conductive agent SP: KS6 : carbon nanotubes = 80: 14: 2.0: 1.7: 1.5: 0.8.

[0033] The preparation method of the positive electrode of lithium ion battery in this embodiment adopts the following steps: mix NMP solvent and PVDF to prepare binder solution, add carbon nanotubes to the binder solution and mix evenly, then add conductive agent SP, KS6 and mix ...

Embodiment 2

[0038] The positive electrode of the lithium ion battery of this embodiment is made up of positive electrode active material, binding agent and composite conductive agent, and positive electrode active material is ternary material (LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 ) and lithium manganese iron phosphate, the binder is PVDF, the composite conductive agent is conductive agent SP, KS6 and carbon nanotubes, and the weight ratio of each component is ternary material: lithium manganese iron phosphate: PVDF: conductive agent SP: KS6 : carbon nanotubes = 84.6: 9.4: 1.9: 1.5: 1.9: 0.7.

[0039]The lithium-ion battery of this embodiment adopts the positive electrode of this embodiment, and then refers to the method of Example 1 to manufacture a lithium-ion battery.

Embodiment 3

[0041] The positive electrode of the lithium ion battery of this embodiment is made up of positive electrode active material, binding agent and composite conductive agent, and positive electrode active material is ternary material (LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 ) and lithium manganese iron phosphate, the binder is PVDF, the composite conductive agent is conductive agent SP, KS6 and carbon nanotubes, and the weight ratio of each component is ternary material: lithium manganese iron phosphate: PVDF: conductive agent SP: KS6 : carbon nanotubes = 75.2: 18.8: 2.4: 1.5: 1.4: 0.7.

[0042] The lithium-ion battery of this embodiment adopts the positive electrode of this embodiment, and then refers to the method of Example 1 to manufacture a lithium-ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com