High-efficient curing agent for preventing cracking of concrete, as well as preparation method and application thereof

A concrete and curing agent technology, applied in the field of preparation of concrete curing agents with anti-cracking function, can solve the problems of large amount of anti-cracking curing agent, low crack resistance performance, high production cost, etc., achieve convenient construction, simple preparation process, reduce cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

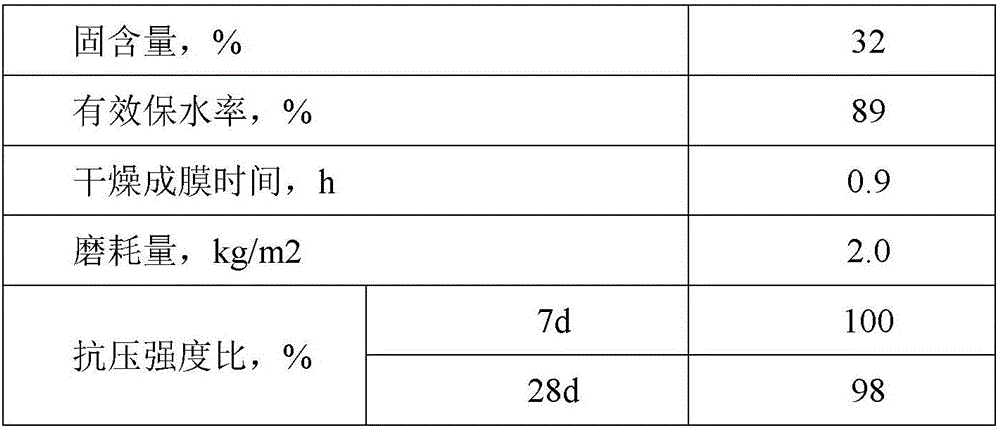

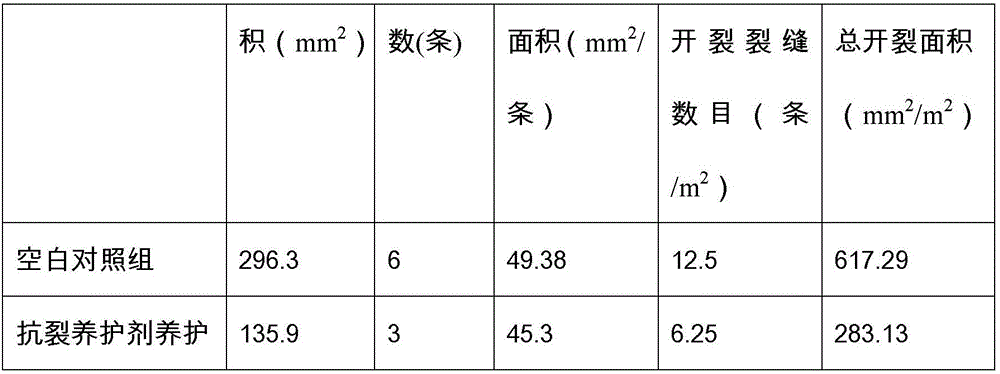

Embodiment 1

[0020] A high-efficiency concrete anti-crack curing agent is prepared by the following method:

[0021] Add 350g of water, 4.2g of sodium hypophosphite as a chain transfer agent, 100g of triethylene glycol monobutyl ether acrylate, and 15g of HPEG into a four-neck flask with a stirrer, raise the temperature to 80°C, keep the temperature for half an hour, and slowly drop Add 5g of ammonium persulfate as an initiator, and a mixed solution of 36g of acrylic acid, 50g of methyl methacrylate and 25g of allyl glycidyl ether. After the dropwise addition is completed, continue the constant temperature reaction for 2.5h, cool to room temperature, and wash with sodium hydroxide The solution is neutralized until the pH value is 7-8, and the polycarboxylic acid copolymer with shrinkage reduction function is prepared. Add 500g of shrinkage-reducing polycarboxylate copolymer, 20g of lauryl alcohol ester, 200g of pure acrylic emulsion, 1.5g of hydroxymethyl cellulose, and 300g of water into ...

Embodiment 2

[0031] A high-efficiency concrete anti-crack curing agent is prepared by the following method:

[0032] Add 350g of water, 4.2g of sodium hypophosphite, 250g of triethylene glycol monobutyl ether acrylate, and 20g of HPEG into a four-neck flask with a stirrer, raise the temperature to 70°C, keep the temperature for half an hour, and slowly add ammonium persulfate dropwise 8g, and a mixed solution of 36g of acrylic acid, 25g of methyl methacrylate and 20g of allyl glycidyl ether. After the dropwise addition, continue the constant temperature reaction for 2.5h, cool to room temperature, and neutralize it to the pH value with sodium hydroxide solution 7-8, a polycarboxylic acid copolymer with shrinkage function is prepared. Add 500g of polycarboxylate copolymer with shrinkage-reducing function, 10g of lauryl alcohol ester, 200g of pure acrylic emulsion, 1g of hydroxymethyl cellulose, and 279.5g of water into the mixer, and stir evenly to prepare high-efficiency concrete anti-crac...

Embodiment 3

[0041] A high-efficiency polymer ceramic water reducer is prepared by the following methods:

[0042] Add 350g of water, 6g of sodium hypophosphite, 100g of triethylene glycol monobutyl ether acrylate, and 17g of HPEG into a four-neck flask with a stirrer, raise the temperature to 75°C, and after holding the temperature for half an hour, slowly add 15g of ammonium persulfate dropwise , and a mixed solution of 36g of acrylic acid, 60g of methyl methacrylate and 30g of allyl glycidyl ether. After the dropwise addition, continue the constant temperature reaction for 2.5h, cool to room temperature, and neutralize it with sodium hydroxide solution until the pH value is 7~8, prepare the polycarboxylic acid copolymer with reducing function. Add 400g of shrinkage-reducing polycarboxylate copolymer, 20g of lauryl alcohol ester, 250g of pure acrylic emulsion, 2g of hydroxymethyl cellulose, and 300g of water into the mixer, and stir evenly to prepare high-efficiency concrete anti-crack c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com