Graphene/waterborne epoxy zinc-rich coating with high corrosion resistance and strong adhesive force and preparation method of graphene/waterborne epoxy zinc-rich coating

A water-based epoxy zinc-rich, strong adhesion technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings and other directions, can solve the problems of limited graphene application and limited compatibility, and achieve improved cathodic protection performance, excellent Corrosion resistance, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

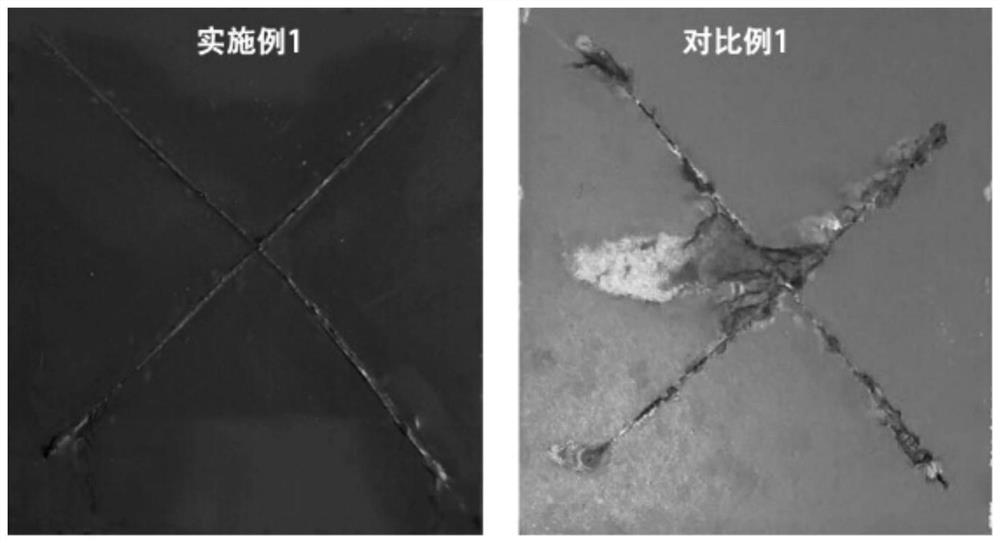

Embodiment 1

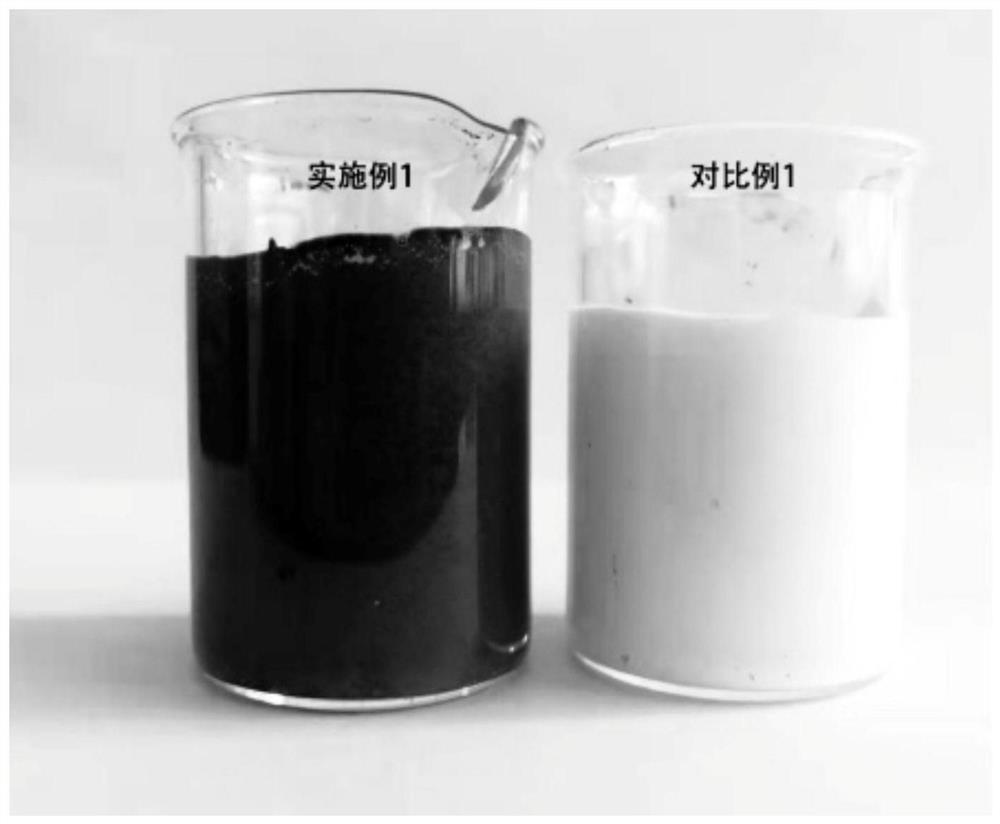

[0032] (1) In terms of parts by mass, disperse 1 part of graphene oxide in 300 parts of deionized water, ultrasonically disperse for 1 h, adjust its pH to 8, then add 3 parts of polyethyleneimine with an n value of 50, and heat up to 60°C, stirring and reacting for 2 hours. After the reaction, use deionized water to filter, wash, and dry to obtain polyethyleneimine grafted reduced graphene oxide, which is hereinafter referred to as modified graphene.

[0033] (2) In terms of parts by mass, take 0.6 parts of modified graphene obtained in step (1) and disperse it into 5 parts of deionized water, add 30 parts of Hexion water-based epoxy resin 6520 and 0.3 parts of TEGO Twin 4100, 500 rev / min and stirred for 15 min to obtain component A of the coating.

[0034](3) In terms of parts by mass, 40 parts of zinc powder, 15 parts of ethylene glycol monobutyl ether and 10 parts of Hexion water-based epoxy resin curing agent 8538 are passed through 4000rev / min, stirred for 30min and mixe...

Embodiment 2

[0036] (1) In terms of parts by mass, disperse 1 part of graphene oxide in 500 parts of deionized water, ultrasonically disperse for 1 h, adjust its pH to 8, then add 3 parts of polyethyleneimine with an n value of 500, and heat up to 60 ° C, stirring the reaction for 2h. After the reaction, use deionized water to suction filter, wash, and dry to obtain polyethyleneimine grafted reduced graphene oxide, hereinafter referred to as modified graphene.

[0037] (2) In terms of parts by mass, take 0.6 parts of modified graphene obtained in step (1) and disperse it into 5 parts of deionized water, add 30 parts of water-based epoxy resin 6520 and 0.3 part of SURFYNOL 104E, stir at 800 rev / min for 15 min , to obtain component A of the coating.

[0038] (3) In terms of parts by mass, 40 parts of zinc powder, 15 parts of ethylene glycol monobutyl ether and 10 parts of water-based epoxy resin curing agent 6870 are passed through 6000 rev / min, stirred for 30 minutes and mixed uniformly, a...

Embodiment 3

[0040] (1) In terms of parts by mass, disperse 3 parts of graphene oxide in 800 parts of deionized water, ultrasonically disperse for 1 h, adjust its pH to 9, then add 8 parts of polyethyleneimine with an n value of 600, and heat up to 70 ° C, stirring the reaction for 4h. After the reaction, use deionized water to suction filter, wash, and dry to obtain polyethyleneimine grafted reduced graphene oxide, hereinafter referred to as modified graphene.

[0041] (2) In terms of parts by mass, disperse 1.5 parts of modified graphene obtained in step (1) into 25 parts of deionized water, add 75 parts of water-based epoxy resin 3540 and 0.3 part of TEGO Twin 4100, and stir at 500 rev / min After 15 minutes, component A of the coating was obtained.

[0042] (3) In terms of parts by mass, mix 60 parts of zinc powder, 25 parts of ethylene glycol monobutyl ether and 25 parts of water-based epoxy resin curing agent 8538. Stir at 6000rev / min for 30min and mix evenly as component B of the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

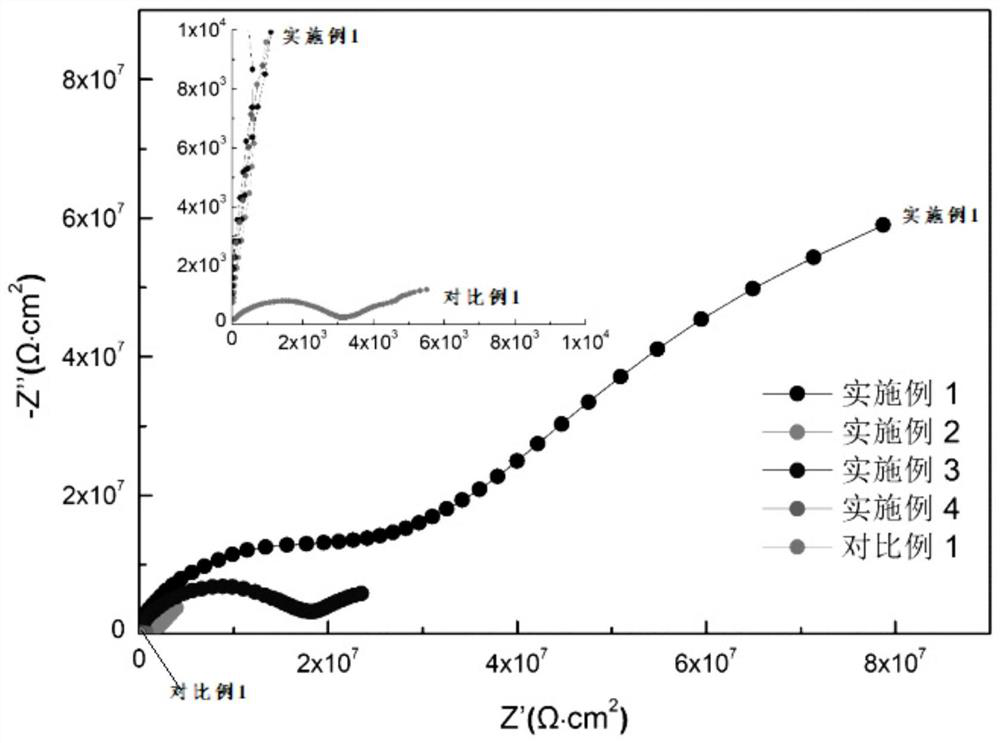

| Impedance value | aaaaa | aaaaa |

| Impedance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com