Silver-carrying titanium dioxide anti-bacterial agent and preparation method thereof

A technology for carrying silver titanium dioxide and titanium dioxide, which is applied in the fields of botanical equipment and methods, fungicides, biocides, etc., can solve the problems of restricting the application of titanium dioxide, poor slow-release performance, affecting catalytic activity, etc., to enhance the photocatalytic antibacterial effect. , Enhance antibacterial effect, prevent discoloration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

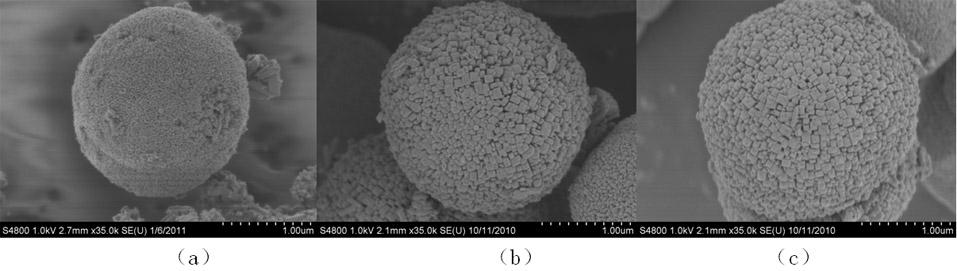

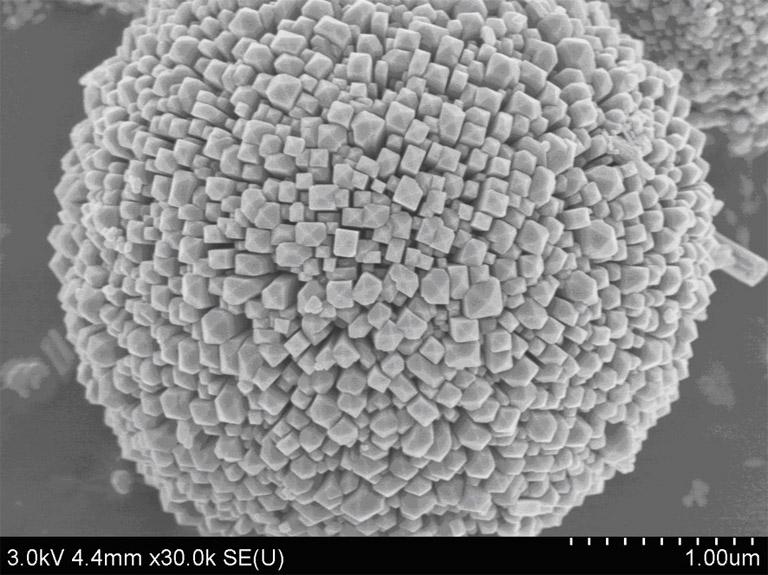

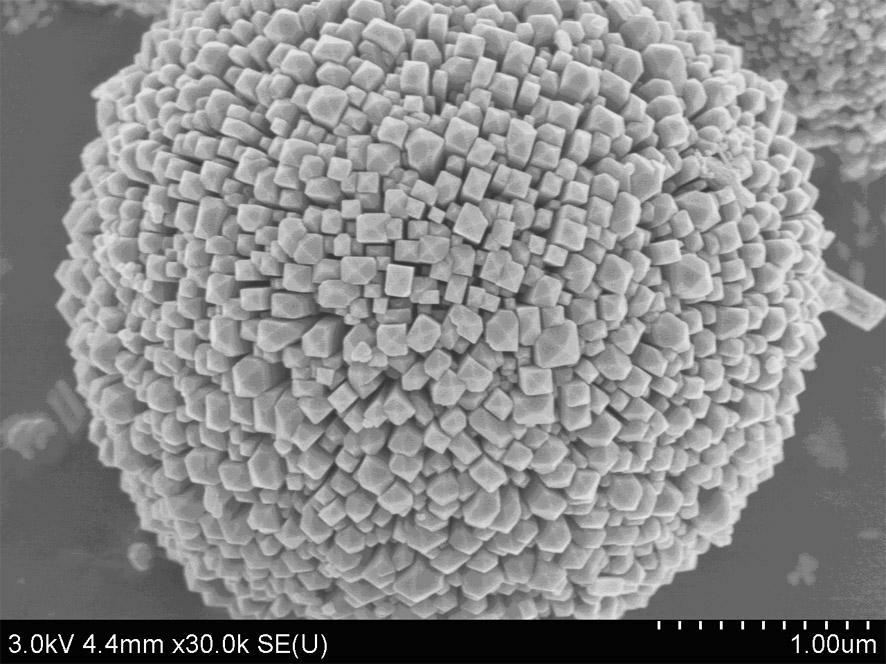

Image

Examples

Embodiment 1

[0016] 1) Dip the equal volume of titanium dioxide in ethanol, put it in a vacuum drying oven and dry it at room temperature to obtain liquid A;

[0017] 2) Prepare silver nitrate ethanol solution according to the mass ratio of titanium dioxide to silver of 100:1, prepare 4,4-bipyridine ethanol solution with the mass concentration ratio of silver nitrate and 4,4-bipyridine at 5.3:9.75, and mix the silver nitrate ethanol solution Mix with 4,4-bipyridine ethanol solution to obtain liquid B;

[0018] 3) Mix liquid A and liquid B, and evaporate at 40°C to obtain powder C;

[0019] 4) Add 80ml of ethanol to C, the speed of the magnetic stirrer is 150r / min, under the irradiation of 254nm, 96 watt ultraviolet lamp, light for 2 hours;

[0020] 5) Suction filtration and drying at 80°C to obtain the silver-loaded titanium dioxide microsphere antibacterial agent.

Embodiment 2

[0022] 1) According to the mass ratio of titanium dioxide and silver as 100:1, configure 25ml of titanium dioxide ethanol solution and 50ml of silver nitrate ethanol solution, place them in the photoreactor and beaker respectively, and pass nitrogen gas to deoxygenate for 10 minutes;

[0023] 2) Under the irradiation of 254nm, 96-watt ultraviolet lamp, the rotation speed of the magnetic stirrer is 150r / min, and the titanium dioxide ethanol solution is illuminated for 30 minutes;

[0024] 3) Under the premise of maintaining the same light and rotating speed, use a peristaltic pump to slowly add part of silver nitrate ethanol solution to the titanium dioxide solution, control the drop rate to 2ml / min, and continue to light for 5 minutes;

[0025] 4) Use a peristaltic pump to add the remaining silver nitrate ethanol solution, and continue to illuminate for 2 hours;

[0026] 5) Suction filtration, drying at 80°C and calcining at 500°C for 4 hours to obtain silver-loaded titanium d...

Embodiment 3

[0028] Titanium dioxide was added to silver nitrate aqueous solution, the mass ratio of titanium dioxide to silver was 100:1, calcination at 500°C for 4 hours after rotary evaporation at 60°C, slow cooling, and pulverization to prepare silver-loaded titanium dioxide microsphere antibacterial agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com