Silicon phosphorus soil conditioner

A soil conditioner, silicon-phosphorus technology, applied in agriculture, fertilization equipment, applications, etc., can solve the problems of reduced phosphorus resource utilization, large phosphorus loss, environmental pollution, etc., achieve industrial application safety, simple preparation process, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

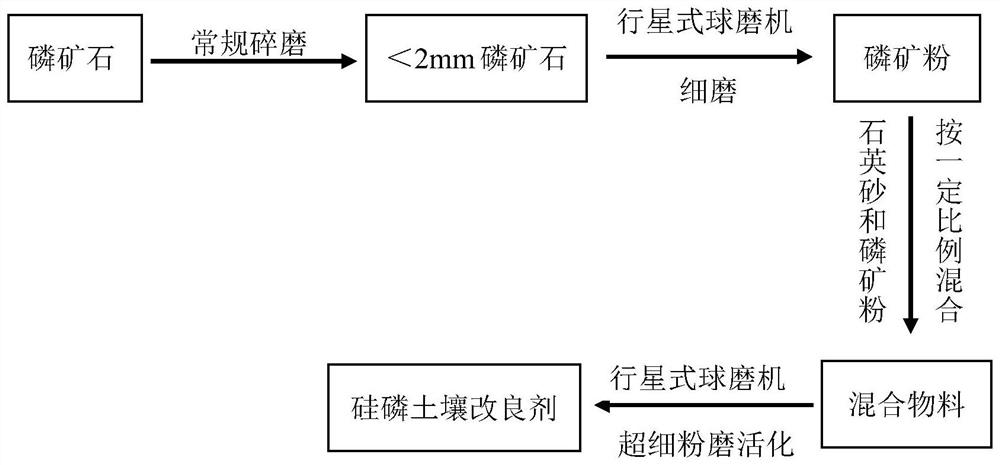

Method used

Image

Examples

Embodiment 1

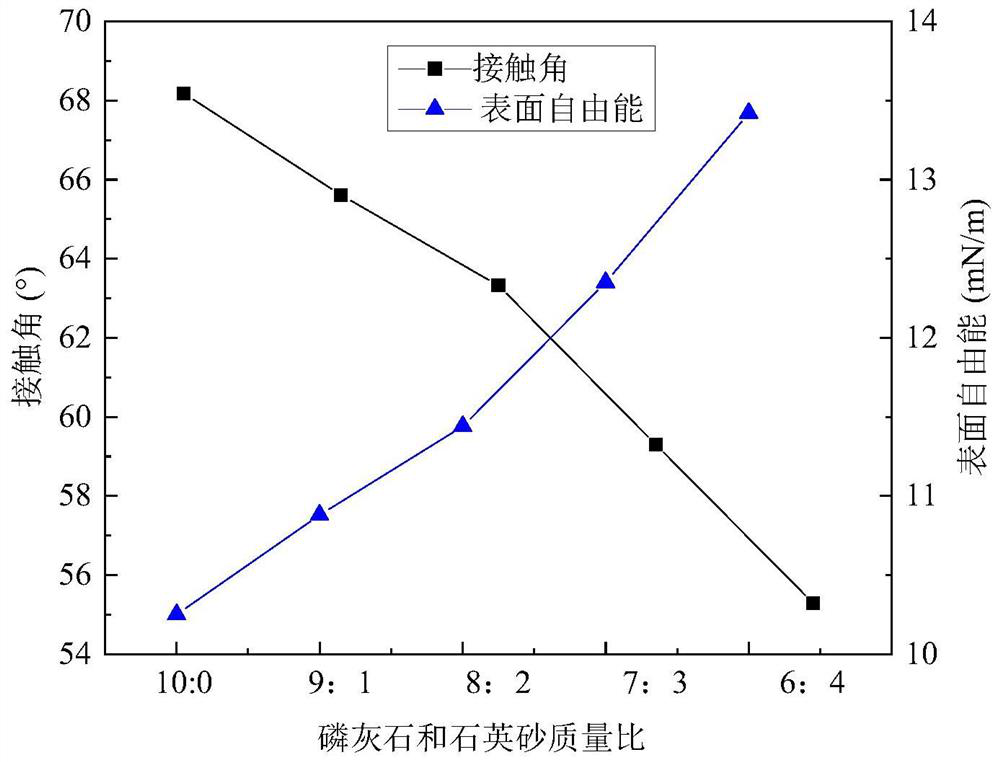

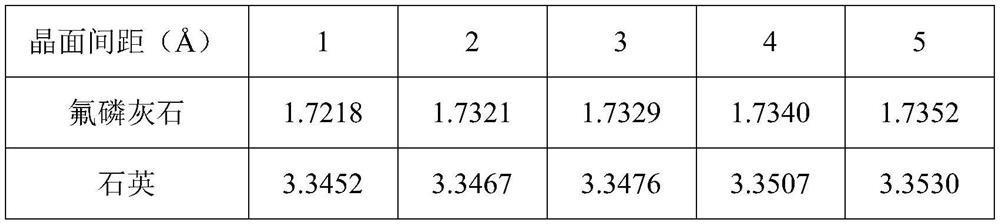

[0025] Use a certain phosphate rock with a phosphorus content of 20.6% and a phosphorus citric acid solubility rate of 8.2%, and pulverize it to a particle size of less than 2mm by conventional grinding means; use a planetary ball mill for fine grinding to obtain a phosphate rock powder of less than 0.15mm; The powder is mixed with quartz with a silicon content of 92% and a silicon citric acid dissolution rate of 0.04% at a mass ratio of 9:1, and the mixed material is ultra-finely ground by a planetary ball mill at a speed of 500r / min, a slurry concentration of 55%, and a time of 150min. After activation, a silicon-phosphorus soil conditioner with a phosphorus-citrate solubility rate of 65.1% and a silicon-citrate solubility rate of 25.8% was obtained.

Embodiment 2

[0027] Use a certain phosphate rock with a phosphorus content of 20.6% and a phosphorus citric acid solubility rate of 8.2%, and pulverize it to a particle size of less than 2mm by conventional grinding means; use a planetary ball mill for fine grinding to obtain a phosphate rock powder of less than 0.15mm; The powder is mixed with quartz with a silicon content of 92% and a silicon citric acid dissolution rate of 0.04% in a mass ratio of 8:2, and the mixed material is ultra-finely ground by a planetary ball mill at a speed of 500r / min, a slurry concentration of 55%, and a time of 150min. After activation, a silicon-phosphorus soil conditioner with a phosphorus-citrate solubility rate of 68.7% and a silicon-citrate solubility rate of 28.4% was obtained.

Embodiment 3

[0029] Use a certain phosphate rock with a phosphorus content of 20.6% and a phosphorus citric acid solubility rate of 8.2%, and pulverize it to a particle size of less than 2mm by conventional grinding means; use a planetary ball mill for fine grinding to obtain a phosphate rock powder of less than 0.15mm; The powder is mixed with quartz with a silicon content of 92% and a silicon citric acid dissolution rate of 0.04% at a mass ratio of 7:3, and the mixed material is ultra-finely ground by a planetary ball mill at a speed of 500r / min, a slurry concentration of 55%, and a time of 150min. After activation, a silicon-phosphorus soil conditioner with a phosphorus-citrate solubility rate of 72.5% and a silicon-citrate solubility rate of 33.9% was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com