Antimicrobial finish on fabrics

a technology of antimicrobial finish and fabric, applied in the field of antimicrobial finish on fabrics, can solve the problems of cross infection by pathogens, development of odor in the inner garment, staining and loss of performance properties of textile substrates, etc., and achieves the effects of not altering the tone, colour, hand feel and appearance of the fabric, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

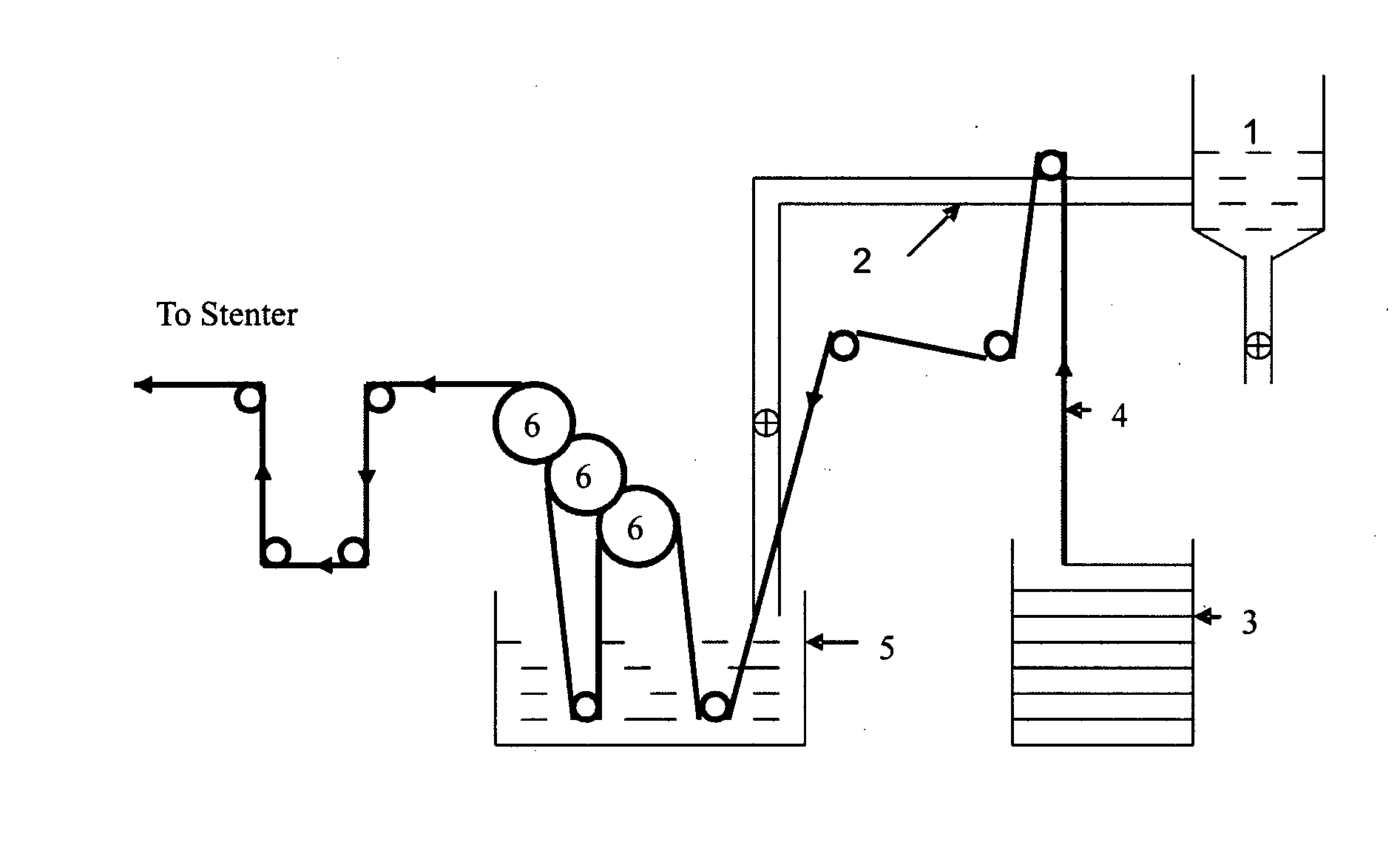

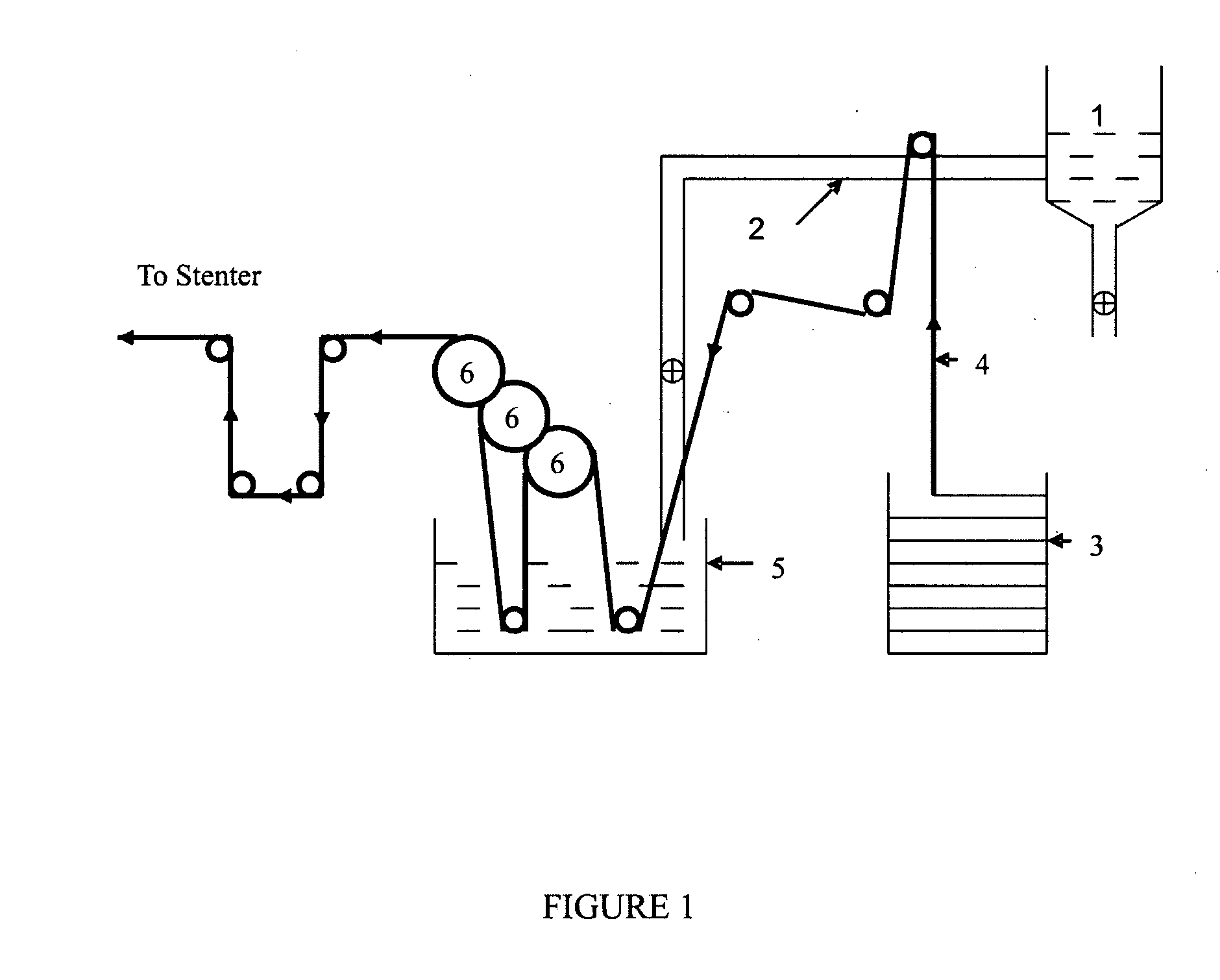

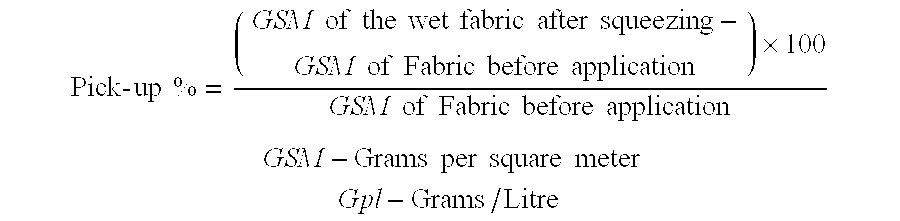

Method used

Image

Examples

example 1

Preparation of Anti-Microbial Formulation (a)

[0077]The anti-microbial formulation was prepared using the following ingredients.

Sr.No.IngredientsQuantity1Isopropyl alcohol985 ml2chloroxylenol12 gm3Terpineol3ml

example 2

Preparation of Anti-Microbial Formulation (b)

[0078]The anti-microbial formulation was prepared using the following ingredients.

Sr.No.IngredientsQuantity1Isopropyl alcohol985 ml2chloroxylenol10 gm3Terpineol5 ml

example 3

Preparation of Anti-Microbial Formulation (c)

[0079]The anti-microbial formulation was prepared using the following ingredients.

Sr.No.IngredientsQuantity1Isopropyl alcohol985 ml2chloroxylenol8 gm3Terpineol7 ml

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com