Method for preparing titanium dioxide nanorod/polypyrrole/dacron compound fabric

A technology of titanium dioxide and composite fabrics, applied in textiles and papermaking, anti-coloring and pollution/anti-fouling fibers, fiber types, etc., can solve the problem of high cost, and achieve the effect of low cost and simple and controllable preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

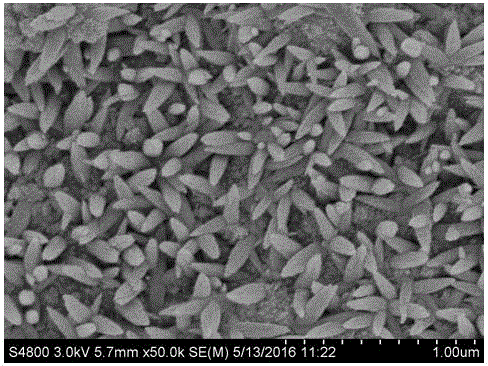

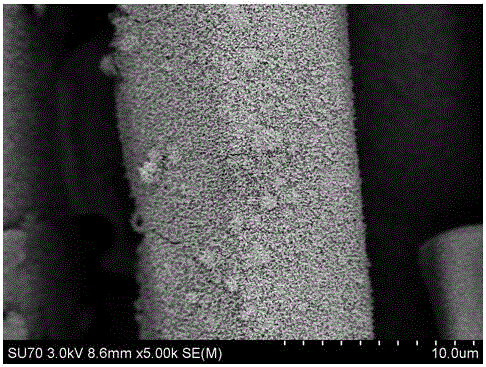

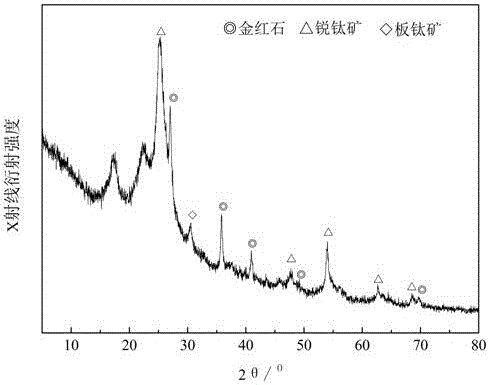

Embodiment 1

[0023] (1) Dissolve ethylenediamine, sodium hydroxide and accelerator 1631 in deionized water to prepare an alkaline amine aqueous solution, so that the mass concentration of ethylenediamine in the alkaline amine aqueous solution is 2%, and the mass concentration of sodium hydroxide is 28%. The mass concentration of accelerator 1631 is 0.08%; a polyester fabric with a specification of 75 D×120 D is selected as a sample, and the size is 5×5 cm 2 The samples were washed once with acetone, three times with ethanol and three times with deionized water, dried, and then

[0024] The polyester fabric was immersed in an aqueous alkali amine solution at a bath ratio of 1:30, reacted at 75 °C for 10 min, washed with water, and dried.

[0025] (2) FeCl 3 and 1,5-naphthalenedisulfonic acid were dissolved in deionized water, and 30 mL of oxidation bath was configured to make FeCl in the oxidation bath 3 The concentration of 0.09 M, the concentration of 1,5-naphthalene disulfonic acid is ...

Embodiment 2

[0031] (1) Dissolve ethylenediamine, sodium hydroxide and accelerator 1631 in deionized water to prepare an alkaline amine aqueous solution, so that the mass concentration of ethylenediamine in the alkaline amine aqueous solution is 2%, and the mass concentration of sodium hydroxide is 28%. The mass concentration of accelerator 1631 is 0.08%; a polyester fabric with a specification of 75 D×120 D is selected as a sample, and the size is 5×5 cm 2 The samples were washed once with acetone, three times with ethanol and three times with deionized water, dried, and then

[0032] The polyester fabric was immersed in an aqueous alkali amine solution at a bath ratio of 1:50, reacted at 55 °C for 20 min, washed with water, and dried.

[0033] (2) Fe2 (SO 4 ) 3 and 1,5-naphthalenedisulfonic acid were dissolved in deionized water, and 15 mL of oxidation bath was configured so that Fe in the oxidation bath 2 (SO 4 ) 3 The concentration of 0.045 M, the concentration of 1,5-naphthalene ...

Embodiment 3

[0039] (1) Dissolve ethylenediamine, sodium hydroxide and accelerator 1631 in deionized water to prepare an alkaline amine aqueous solution, so that the mass concentration of ethylenediamine in the alkaline amine aqueous solution is 2%, and the mass concentration of sodium hydroxide is 28%. The mass concentration of accelerator 1631 is 0.08%; a polyester fabric with a specification of 75 D×75 D is selected as a sample, and the size is 5×5 cm 2 The samples were washed once with acetone, three times with ethanol and three times with deionized water, dried, and then

[0040] The polyester fabric was immersed in an aqueous alkali amine solution at a bath ratio of 1:30, reacted at 75 °C for 10 min, washed with water, and dried.

[0041] (2) Fe 2 (SO 4 ) 3 and 1,5-naphthalenedisulfonic acid were dissolved in deionized water, and 20 mL of oxidation bath was configured so that Fe in the oxidation bath 2 (SO 4 ) 3 The concentration of 0.045M, the concentration of 1,5-naphthalene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com